3D printing technology is being pushed to its limits. And the results are amazing. A team of researchers at the Autodesk has devised the ‘Project Escher’ which uses 3D print technology to combine the power of several printers to fabricate complex parts together. This increases the production capacity and speed by 90%, as reported by the FastCoDesign.

3D printing has been difficult to implement in large-scale additive manufacturing due to its time taking processes. It is measured in weight per hour symmetries and hence, production becomes impossible in the case of heavy equipment. In fields like aerospace, construction, and automation, though there is a need for a technology that can shape complex geometrics, the 3D printing technology, although being suitable, gets, therefore, restricted.

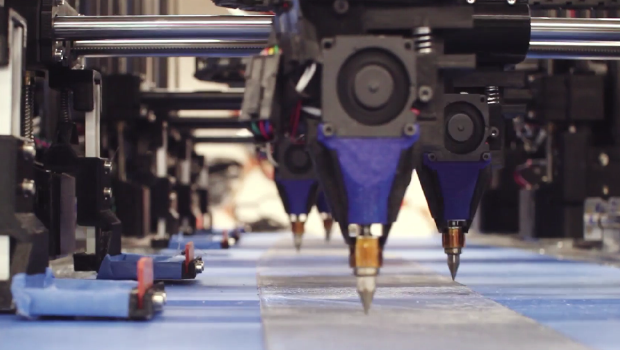

The Escher model aims at using a gantry system that contains suspended ‘bots’, to which a part of the model can be assigned for manufacturing and then they can be collectively assembled. Corey Bloome, Autodesk’s hardware head of the project, told FastCoDesign that the bots can be added as per requirement, increasing the speed and capacity manifold.

He further went on to add that robotic arms could be added to the gantry system which could increase its assembling capacity and make the possibility of printing complex objects in one sitting a reality. This could also lead to the manufacturing of cars in just one sitting.

As of now, the Escher project continues to be Autodesk’s in-house project. But in future, it plans to enlist companies which can experiment and process their services in the Escher Project. It is only then that the real utility and power of this 3D printing technology will be justified.

Source: Archdaily.com