Copper-based filaments made of copper and PLA are available in different formats and are used in 3D printing. It is also used in lost wax 3D molding technique. But, copper loses its properties like conductivity while being 3D printed.

Researchers from the Daihen Company and Osaka Prefecture have found a new alternative to this problem. They use a copper alloy powder and an M2 metal powder. They rely on 3D laminate shaping to mold the metal into various shapes. This technique will make 3D printing using copper alloys a widespread phenomenon. Copper is an extremely good conductor of heat and 3D printing the same material will shorten the production time. Researchers are looking on to use copper for sectors like aerospace, health, and automotive industries.

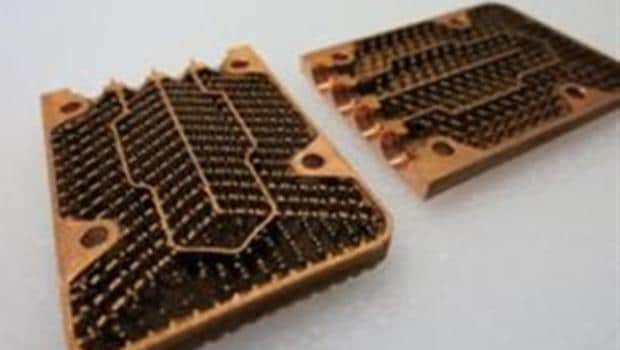

In addition, laser reflectance makes it difficult to 3D printed laminated laser. But it will be possible to 3D print laminate layers using copper with an M2 3D printer with a 4000W laser. This technique reduces production time, provides production facility, and leads to the manufacturing of single structures. Customer’s specific demands can now be catered to, and even small demands can be fulfilled. Mold storage and inventory will now be a thing of the past.

Water-cooled torches are another area where copper 3D printing can be used. Due to the alloy’s conductive features, the results display high cooling properties and reduction in weight and size. Using the pure form of copper, the electrical conductivity can be increased to 90% and the tensile strength of the product can be greatly improved. Also, the technique can change the properties of the molded component, and hence it can be used for related applications. If all these applications are put to practical use in an extensive way, copper tool manufacturing will witness a radical change.