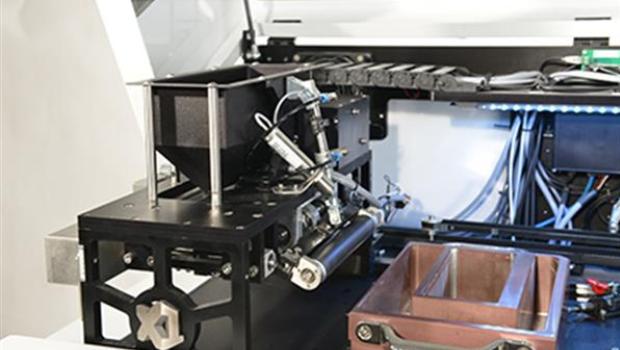

Innovent is a 3D printer by ExOne. Headquartered in Pittsburgh, Pennsylvania, ExOne is making modification in the printer to equip it to process metal and ceramic powders at less than 10 microns. The users of the Innovent will be able to access the modification package.

The Innovent 3D printer can print both ceramic and metal objects with superior surface finish and high density. It is used for prototyping and manufacturing uses. It can also be used for industrial and laboratory research. The company has now come up with an upgraded fine powder version of the machine. These upgrades will be applied to its large-format printing system and M-Flex system.

Jim McCarley the CEO of ExOne said that this new technology will complement the processes of Metal Injection Molding and Powder Metal industries. ExOne has introduced a new 3D printing material for its printers. Stainless steel 316L is a 300 Series stainless steel used in automotive, chemical processing equipment and surgical instruments. This material is ExOne’s second single metal alloy for industrial 3D printing applications. The ExOne customers can now order “job shop” 3D printed products made using 316L. The material will be available for commercial use from 2017.

This new 3D printing material will allow better manufacturing of commercial, automotive, and energy applications. This will boost the company’s credibility and future prospects. The company will produce new 3D printing products using binder jetting.

ExOne provides 3D printing services and equipment to makers all around the globe. It has an in-house printing unit. Apart from supplying equipment and material, the company is also engaged in taking orders and producing 3D printed products on orders. General Electric acquired a huge number of 3D printers from ExOne this year. These printers were set up at the GE additive manufacturing facility in Pittsburgh. GE plans to invest further in the company in the next three years.

Source: 3ders.org