Fused Deposition Modeling (FDM)

- FDM technology can go about building quick prototypes with strength and speed, at a very economical price in a wide range of thermoplastic materials, which makes it a very attractive option.

FDM 3D Printing Service

Get your initial prototype faster & cheaper using our FDM services. Our facility is equipped with 15 FDM machines of different build volumes which runs 24/7 and have a passionate team to serve you.

Quick Online Quote

Upload files in Get Quote section and get quote within 4 hrs

Technical Competency

Technically qualified team in various mfg. technologies

Competitive Pricing

Highly competitive price and bulk discounts also available

NDA & IP Protection

All designs and data are kept in highly secure private server

Overview

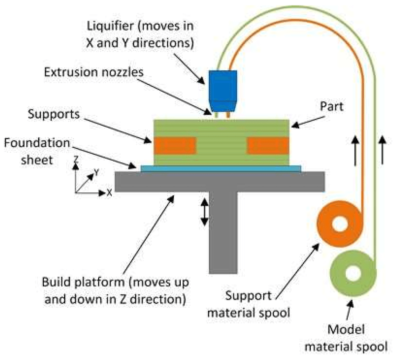

Fused Deposition Modeling (FDM), or Fused Filament Fabrication (FFF), is an additive manufacturing process that belongs to the material extrusion family. In FDM, an object is built by selectively depositing melted material in a pre-determined path layer-by-layer. The materials used are thermoplastic polymers and come in a filament form.

I. A spool of thermoplastic filament is first loaded into the printer. Once the nozzle has reached the desired temperature, the filament is fed to the extrusion head and in the nozzle where it melts.

II. The extrusion head is attached to a 3-axis system that allows it to move in the X, Y and Z directions. The melted material is extruded in thin strands and is deposited layer-by-layer in predetermined locations, where it cools and solidifies. Sometimes the cooling of the material is accelerated through the use of cooling fans attached on the extrusion head.

III. To fill an area, multiple passes are required (similar to coloring a rectangle with a marker). When a layer is finished, the build platform moves down (or in other machine setups, the extrusion head moves up) and a new layer is deposited. This process is repeated until the part is complete.

Support structure is essential for creating geomentries with overhangs in FDM because melted thermoplastic cannot be deposited on thin air. Surfaces printed on support will generally be of lower surface quality than the rest of the part. For this reason, it is recommended that the part is designed in such a way to minimize the need for support.

Support is usually printed in the same material as the part. Support materials that dissolve in liquid also exist, but they are used mainly in high-end desktop or industrial FDM 3D printers. Printing on dissolvable supports improves significantly the surface quality of the part, but increases the overall cost of a print.

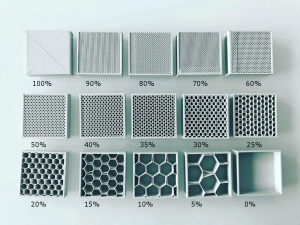

FDM parts are usually not printed solid to reduce the print time and save material. Instead, the outer perimeter is traced using several passes, called the shell, and the interior is filled with an internal, low-density structure, called the infill. Infill and shell thickness affect greatly the strength of a part. For desktop FDM printers, the default setting is 25% infill density and 1 mm shell thickness, which is a good compromise between strength and speed for quick prints.

Applications

- Prototypes for form, fit and function testing

- Prototypes directly constructed in production grade materials like ABS, Nylon

- Low-volume production of complex end-use parts

-

Patterns for Sand casting & molds with lesser detailing

- Tooling / Jigs & Fixtures

materials

PLA

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

ABS

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

PETG

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

Nylon

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

Poly Carbonate

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

Polypropelene

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

TPU

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

HIPS

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

PVA

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

Design Rules

Minimum Wall thickness: 1.2 mm

Minimum details size: 2 mm (for text/ hole diameters etc)

Layer thickness: 0.1 mm – 0.3 mm

Max dimensions: 650 x 600 x 600 mm. Large parts can be created with assembling individual parts by interlocking designs or glueing together.

Standard Accuracy: ± 0.3% (with lower limit on ± 0.3 mm).

Lead Time: Minimum 2 working days for despatch

Surface finish: visible layers with texture.

post processing

Basic: Support Removal & Sanding / Polishing

Add on: Primer, Putty, & Coating/ Painting

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL

Frequently Asked Questions

Fused Filament Fabrication (FFF) is the same process as FDM. The two terms can be used interchangeably. FFF uses a filament material that is layered and then fused, just like FDM. Fused Deposition Modeling was initially invented and trademarked by Stratysys, Inc. in 1988. The patent did not expire until 2009. To avoid trademark violations, other 3D printing companies began to reference the technology as Fused Filament Fabrication.

– 3D CAD design

– Model Slicing

– Preparing machine

– Transferring Gcodes to machine

– 3D Printing

– Supports removing

– Polishing

– Dimensional inspection

– Packing

-Machine price is less than SLA, SLS & SLM as there is no costly equipment utilized , which produces laser. Simply by thermal heat plastic is melted here.

– Raw materials are also cheaper & available every where.

STL file is input for slicing software’s & Gcodes are input file formats for FDM machines.

– Layer shifting

– Layer separation

– Curling

– Poor surface above supports

Due to layer wise deposition of plastic in circular cross-sections.

No. Its not recommended to use FDM printed parts for leak proof applications.

For general plastics like ABS, PLA, PP, PETG, Nylon extruder nozzle temperature will be between 230 – 250 Deg C.

For engineering plastics like PC, ULTEM & PEEK extruder nozzle will be between 310 – 450 Deg C.

We can get translucent parts in PETG & PC material. 100% transparent may not be possible.

Max size of part we can print is 1000 x 1000 x 1000 mm.