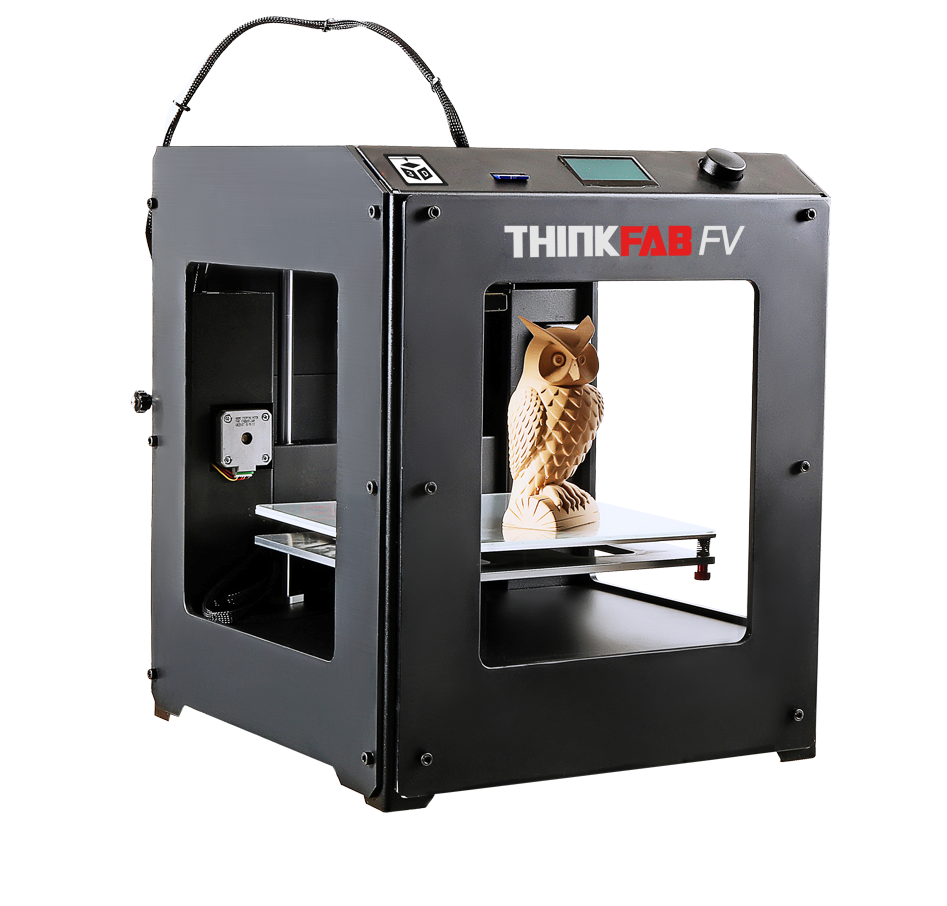

3D printing is a new & upcoming technology and because of that most 3D printers aren’t very sturdy enough like PCs, 2D printers. 3D Printers have to well taken care of to get quality prints and also to avoid regular repairs. In this article , we will be discussing the mechanical maintenance of 3D printer to help you get better quality prints.

Here are some of the tips to keep your printer nicely maintained

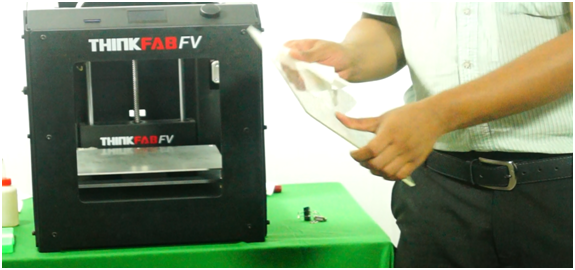

1. Keep the build plate clean

While taking 3D prints, we apply glue to the build plate to avoid warping of the prints. Because of the glue, some molten plastic and foreign particles get stuck to the build plate. Due to this, prints don’t come proper and build plate will have an irregular surface. To avoid that, always clean the build plate after every print.

We can clean it using cloth and by dipping it in the warm water.

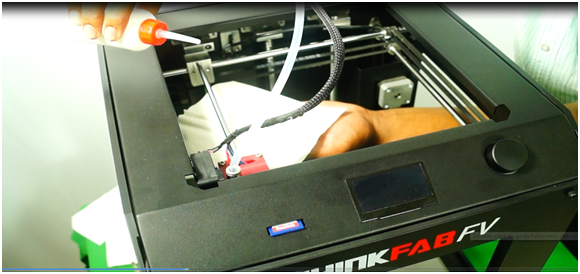

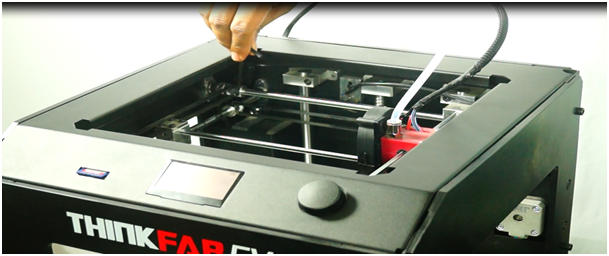

2.Lubricate the X & Y axes

While printing ,the X & Y axes are there in continuous motion along with the Printer head. The lubrication fades along with the deposition of dust on these rods over a period of time. This makes the movement of the axes stiffer and they demand lubrication for a smooth motion.

Wipe the rods to clean the dust and lubricate it with oil and manually move it to check for the lubrication .

3.Lubricate the Z axis

The Z axis of a 3D printer is generally a lead screw and it should be lubricated with a solid lubricant or grease to sustain the lubrication over it .

Lubricate the Z axis with grease and move it manually to the extremes to get the uniform lubrication.

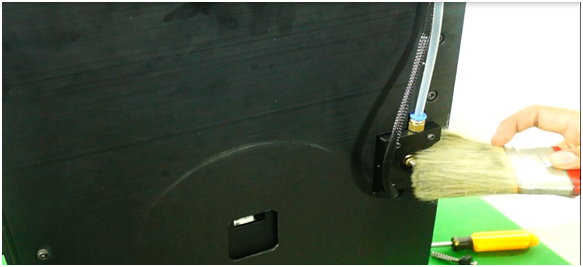

4.Clean the Extruder

The filament passes through the rollers for the extrusion in the cold end of the Extruder. During extrusion/plastic deformation some particles of the material wear off on these rollers and get stuck to it. It changes the geometry of the rollers which can make the further extrusions improper.

These rollers can be cleaned using toothbrush which will help the extruder function smoothly and give quality prints.

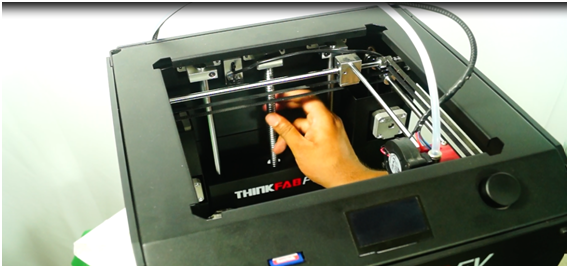

5.Tighten the Pulley Screws

The pulleys are installed on the X & Y axes of the printer. Due to the continuous motion of these axes there are vibrations in the system which result in the loosening of the pulley screws . It leads to a misaligned system and the quality may reduce .

It is a good practice to tighten the pulley screws periodically with the allen keys.

Regular maintenance of a 3D printer gives long life to the printer and helps avoid costly repairs. We hope this tutorial gives you an idea on how to maintain a 3D printer. If you have any suggestions, feel free to add those in the comments section below.