Introduction:

In the present situation like this with the outbreak of respiratory illness, we stood to take up the challenge in manufacturing the medical devices through 3d printing to help the affected patients.As we all know a ventilator is a machine that provides mechanical ventilation by moving breathable air into and out of the lungs, to deliver breaths to a patient who is physically unable to breathe, or breathing insufficiently. A Ventilator Splitter is an easy solution to differential ventilate people in different sizes and with different compliance to overcome the crisis of ventilation needed in the hospitals.

What is the need?

When we talk about the patients, we can expect to have different lung compliance and lung volumes and respiratory & inspiration patterns. It’s difficult to maintain the same amount of flow when we have dissimilarities in the patients. In this pandemic, it’s difficult for the doctors as they get worse or who are getting better patients. Overtime they realize it is not that simple as splitting the oxygen levels.This device allows one ventilator to support up-to 2-4 patients during times of acute equipment shortage such as the current COVID-19 pandemic.

Designing

The design for manufacturing of the component is given by our client company. The device was designed in two different models according to their need where they can ventilate different patients using a single ventilator.

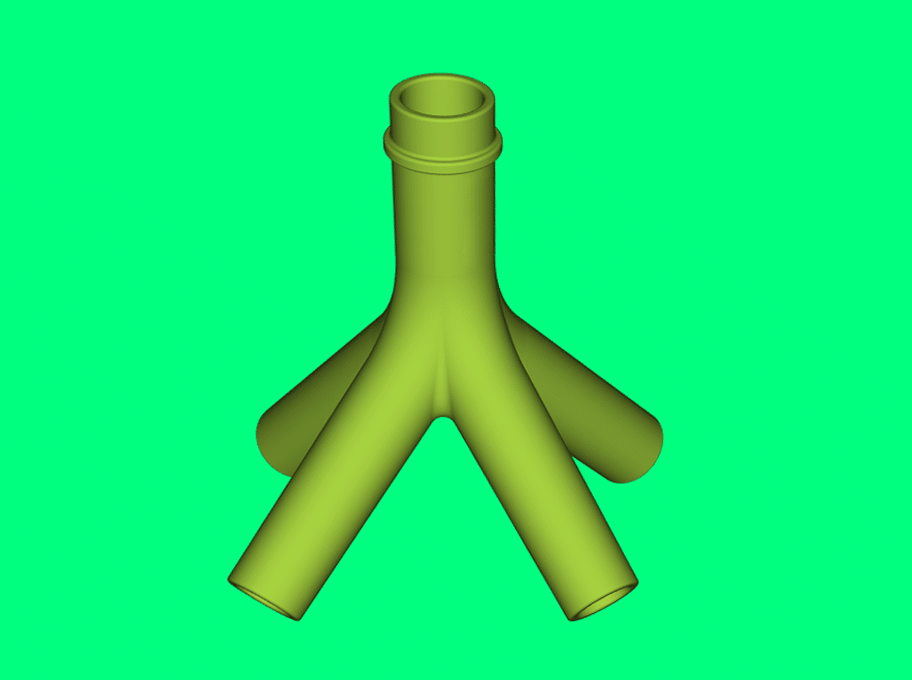

Design 1

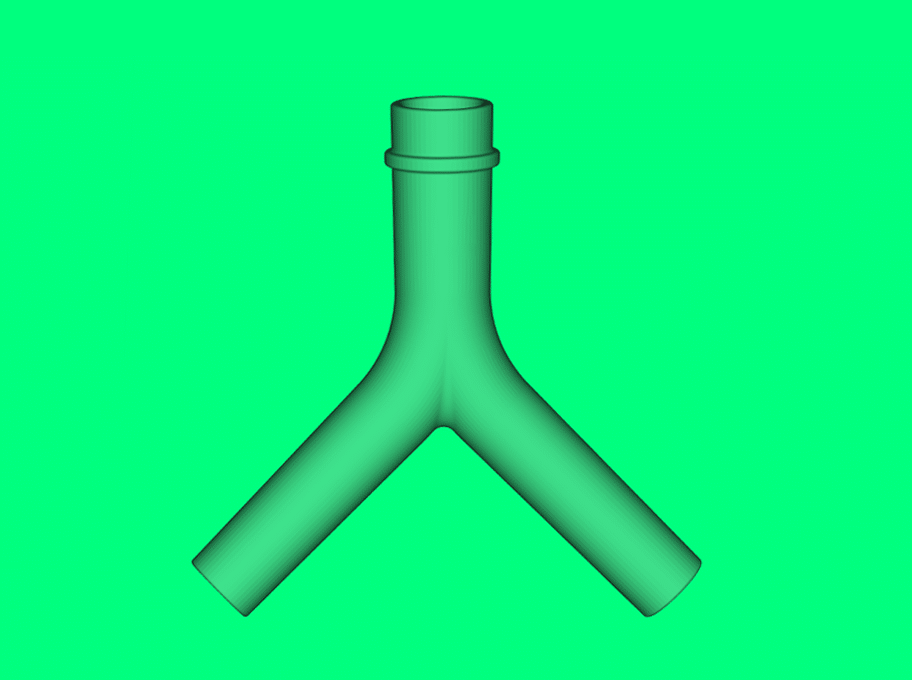

Design 2

Manufacturing

We are using a high-end additive manufacturing technology to 3D print this device which is known as MJF(multi jet fusion). Once the device is 3d printed, it goes under a curing process to get the final outcome.The 3d printed ventilator splitter device is bio-compatible and environmental friendly. We at, think3D make utmost care in the production of the medical devices and components.

How does it work?

The component which we are manufacturing here helps the doctors to alter the flow of passage through the same ventilator,multiple combinations of this device can be configured to allow a single machine to be used up to 3-4 patients. This device can be lifesaving when the number of critically ill patients requiring breathing support is greater than the number of available ventilators. This device project has been given to us by WIPRO company as it is still a rudimentary set up, this splitter can actually change the volumes which are going into each lungs of the patients.

All the manufactured components are shipped to our Client Company which is WIPRO. The assembly of the individual components into a complete equipment is done at our Client company.

We have successfully delivered the required quantity to the company within their stipulated deadline and are planning to manufacture more of these products to serve the requirement in this current situation. The manufacturing was undertaken by Think3D Labs Pvt Ltd, AMTZ campus, Visakhapatnam.

If you wish to 3D print these with us, feel free to contact us at +91 8106484999 | +91 8101986299