The impact of Captain America, the Iron Man, and its allies are making their presence felt in the 3D printing community. Though a number of 3D printed Iron Man suits are flooding the market, this 3D printed Ultron Mask is truly amazing.

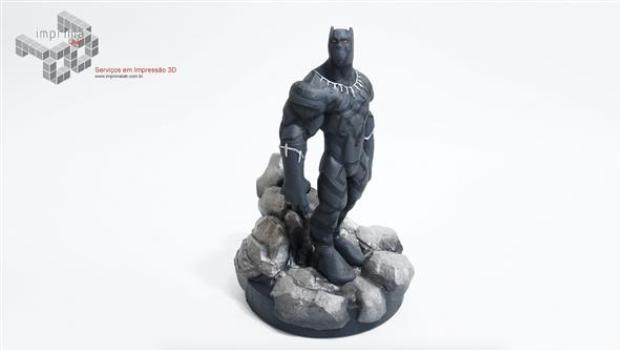

Sebastian Dominguez, a connoisseur of art collectables and action figures. He is a digital sculptor and professor of 3D modeling at the Image Campus in Buenos Aires, Argentina. Domingue loves to make his own DIY projects from his favourite movies. He selected and designed an amazing Black Panther model from the Marvel series. It was 3D printed by a specialist and industrial designer Pedro Augusto Coelho of ImprimaLab.

Dominquez’s latest project is the Captain America, Civil war. The character of Black Panther was his choice for 3D modelling. Black Panther was vested with superior speed, flexibility, and resilience, and his suit of ‘vibranium’ featuring retractable claws was captivating. Hence this character became Dominguez’s choice for 3D printing. Corey Smith sketched the designs of the model. It was 3D printed in the ImprimaLab BY Pedro of Brazil. Imprimalab works with 3 D print artists to showcase innovative 3D designs. Pedro is a 3D printing artist who designs models from movies. His notable works include the 3D printed characters of movie memorabilia, which are -the bust of Chappie, the South African robot-cop turned gangster, a Zombie replica of the Hulk and a Mad Max mouthpiece.

The Black Panther was divided into 3 parts – from head to waist, from waist to feet, and the arms were separately printed. This segmentation made 3D printing easier and saved on the wastage and cost of support material. The 3D printing took about 28 hours, and the object was printed with a 100-micron resolution. The stand was 3D printed at 200-microns in 11 hours. The total amount of used ABS filament was 400 grams.

Source:3ders.org