COVID-19 Pandemic has brought some unfathomable challenges to all of humanity. Especially the health care system around the world is in shambles. Governments have confirmed the inexplicable shortage of PPEs(personal protective Equipment), Testing kits, and Ventilators hence asked the manufacturers with an unprecedented call to action.

By lieu of our presence in Andhra Pradesh MedTech Zone, India’s first dedicated medical device manufacturing zone, we are deemed essential services and are mandated to manufacture various kinds of medical devices for prevention and diagnosis of coronavirus.

What have we done and still doing?

We have collaborated with various stakeholders like government organizations, customers and business partners. We empowered them by sharing our cutting edge technological resources to bring out innovative and rapid solutions. Our technologies include 3D printing, Laser Cutting, Injection Molding, CNC milling, CNC turning, Vaccum casting, and 3D Scanning.

Below is the brief description of various projects undertaken at our manufacturing facility:

Face shield

A face shield is a PPE (Personal Protective Equipment) which is designed to offer protection from viral fluids/droplets. Specifically, It helps Doctors and Health care workers who are in direct contact with COVID19 affected on a daily basis. We have manufactured the above-shown face shields using our Laser cutting machines with our beloved partner Biosense Technologies Pvt Ltd

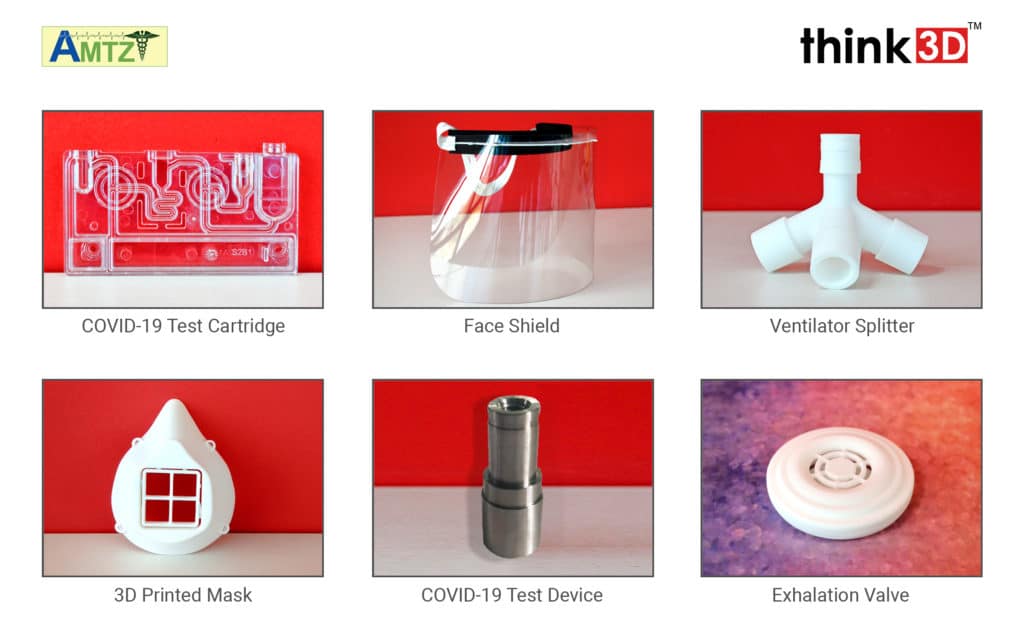

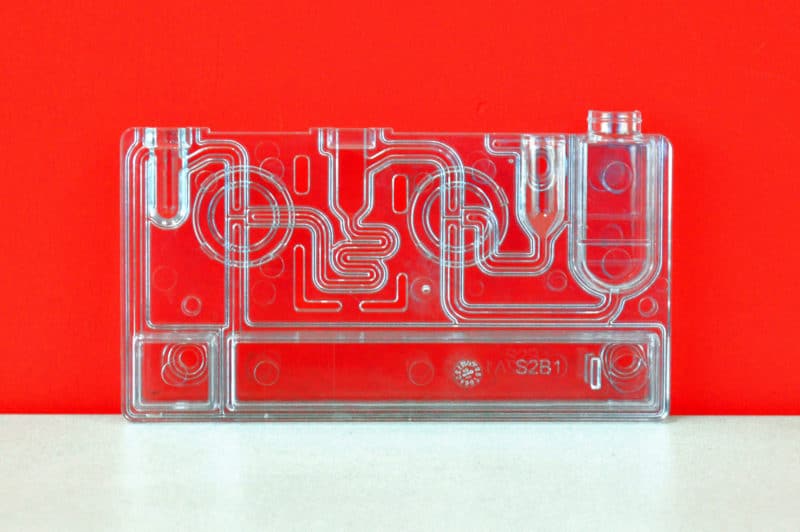

COVID-19 Test Cartridge

There is a great necessity for rapid testing of infection to contain the spread. Implementing this COVID-19 test cartridge has huge time and cost savings when compared to laboratory screening which takes days to give results and is costly. It will help control the spread by identifying the infected rapidly and accurately. We are manufacturing thousands of test cartridges in our Injection molding machine in collaboration with our business partner Molbio diagnostics Pvt ltd.

Ventilator Part

We are making devices to insert the cartridge mentioned above and get the test result.These designs are made by a diagnostic company located in the medical device manufacturing zone and we are manufacturing the components with CNC Turning and Milling technology. These are high precision parts with a tolerance of 3 – 5 microns.

Exhalation Valve

The exhalation valve is designed to release hot, humid exhaled breath quickly, helping to prevent an unpleasant build-up of heat inside the face piece and increase comfort for respirator wearers. Breathing valves are an improvement to functionality and effectiveness, only. We have 3D printed these valves in Selective laser sintering technology.

Ventilator Splitter

In the present situation like this with the outbreak of respiratory illness, we stood to take up the challenge in manufacturing the medical devices through 3d printing to help the affected patients. A Ventilator Splitter is an easy solution to differential ventilate people in different sizes and with different compliance to overcome the crisis of ventilation needed in the hospitals. We have 3Dprinted 2 way and 3-way ventilator splitters and distributed to hospitals.We are manufacturing these splitters with Multi Jet Fusion technology.

3D Printed face mask

Unlike regular face masks that filter the fluids and act as air filtration, 3d printed face masks will also act as a physical barrier to the environment. Due to the scarcity of regular masks in the market, INDIAN NAVY, Eastern Naval Command in Vizag has reached out to us to manufacture 3D printed face masks. We have 3D Printed 200 face masks as asked and handed over to the Indian Navy officials. The 3D printer is of Selective laser sintering technology consisting of strong and flexible Nylon plastic Biocompatible material.

“We will be the barrier to connect the need and the solution with our technological resources.”