Hope that you are clear with the basic questions – why you want a 3D printer and how much are you willing to spend on it. If not, you can have a glance at this article.

Now, let’s move on to the next important consideration – the technical aspects you need to understand.

Printing Technologies

It’s always good to start with the understanding of popular technologies used in the Desktop 3D printers. Though there are 4-5 technologies like SLA, SLS, FDM, Polyjet etc, SLA and FDM are the most popular ones used in desktop printers. In fact, FDM is the most used technology, since it can deliver lowcost-low maintenance home printers easily.

Fused Deposition Modeling (FDM)

The FDM printers use thermoplastic filament which is heated till the melting point and then the molten plastic is placed layer by layer to form the model. This is the most widely used technique for 3D printing because it uses real engineering grade thermoplastic, the parts that are built with this material are stronger and very durable. Parts can be directly built into ABS, polycarbonate, nylon and other materials.

Popular 3D Printers using this technology: Printrbot, Makerbot, Ultimaker, Stratasys Mojo, Cube, Up Plus!

Stereolithography (SLA)

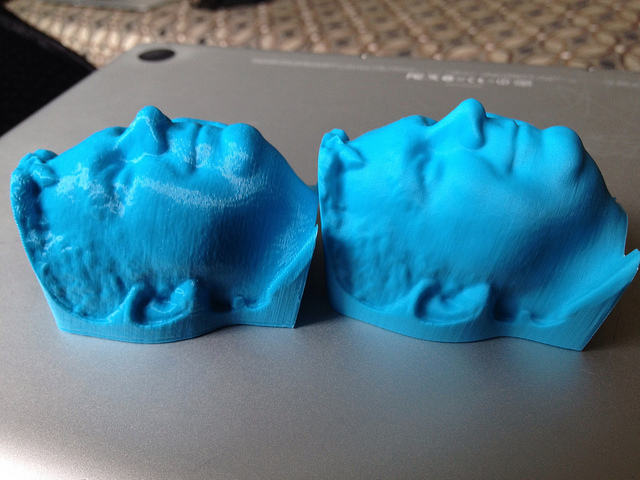

The Stereolithography or the SLA is a rapid proto-typing process or rapid modeling which makes 3D models from photo-sensitive resins or photo polymers. It uses a UV/ laser that are controlled by the computer to make a 3D model layer by layer. SLA is better than FDM on two accounts – the pieces are crisp and highly detailed and the speed of production is very high. Unlike the FDM process, in this process after the production the model needs to undergo post-curing process to impart strength to the model. These printers are more expensive. Projet series from 3D systems is very popular.

Machine Build

Most 3D printers come fully assembled and ready to print, but some are sold as kits that you assemble yourself. The prebuilt models are easier start with, but the kits offer better insight into how these printers work, and allow you to customize and tweak them yourself when they are up and running.

Some printers have an enclosed build area which is safer but costlier, while others have an open print area which is cheaper and offers more visibility. Printers that have a solid metal frame tend to vibrate less while printing at a very high speed, so there will be relatively less resonating waves that show up in the prints. But many wood and plastic frame 3D printers are lighter and easier to move around your home or office.

Printers with a direct drive system, as opposed to a belt and pulley drive system tend to have backlash when changing directions, and hence a more accurate X-Y resolution.

Printing Platform

Heated printing platform is also an aspect to lookout for if you want to use ABS. Heat beds are used because they dramatically improve print quality by keeping the extruded plastic warm and thus preventing warping. Warping is a common condition caused by plastic on the edges of the part cooling down at an uneven rate when compared to the plastic inside of the part, thereby causing deformation. Many of the latest 3d printers are equipped with heated platforms.

3D printers usually build at a layered height of 0.1mm. If the platform height is more or less than the layer height, then the first layer will not stick well with all the sides and it’s more likely that it will peel off or the worst could happen – like falling off the platform. So, “Leveling” your platform is an important aspect you should consider to get good prints. The process of leveling the platform may vary a little from printer to printer. Look for features like auto-leveling and auto-calibration system in the printers if they are coming in your budget.

Dimensions

You may not bother too much about the weight of the machine or the volume of the printer frame, but typical desktop printers weigh around 10-15 kilograms and occupy the space of a tiny refrigerator!

Remember that the desktop printer you are about to buy can only build an object measuring a few inches on each side. If you shell out more money, you might be able to build objects of the size of a basketball. Hence, carefully read the print dimensions before you buy, if it suffices your requirement.

Large print platforms of at least 9 x 9 x 9 inches are quickly becoming an industry standard. The advantage of having a huge build volume is that you can print large parts without having to digitally cleave the model. In addition, you can also print lots of different parts at once. But, printing bigger objects will take a lot of time, and most of the objects you are interested will be accommodated in a size of 200×200. So, it’s a tradeoff between capacity and cost.Makerbot mini can build objects of dimensions up to 100 L x 100 W x 125 H in mm, while Ultimaker 2 can yield up to 230 x 225 x 205 mm.

Material / Filaments

Typically 3d printers use 1.75 or 3mm filaments, which are widely available on rolls in a range of colors. Majority of desktop printers use FDM technique and have only a few plastics in use, ABS and PLA being the most popular. ABS is tough and requires a heated print platform, while PLA is compostable, glossy and offers more variety in color. PLA and ABS have different operating muzzle temperatures. Choose your application and go for the printer that supports the material of choice. Most of the printers can support a range of temperatures from 180° – 260° C and can operate with both the materials, but the best performance can be obtained by the material recommended by the manufacturer.

Most 3D printers use filament spools that are interchangeable. The exceptions are the printers from the bigger companies like Makerbot or Cubify Cube from 3D Systems, which lock you in, and require special (costlier) cartridges, as they and do not support other filaments. Open filament system, allows you to choose and swap out any filament type and is cheaper. Lock-in filament system offers ease of use and low maintenance.

Printer Software

Do have a look at the software support offered. Few of the major manufacturers like ultimaker, Cube and makerbot are offering proprietary softwares for slicing and printing. Most of the other printers have a recommended software, and often are compatible with a host of open softwares like slic3r, meshlab, cura and other paid softwares like kisslicer, meshmixer, netfabb etc.

Another point to look at is the OS compatibility. Most of the printers are compatible with windows and macintosh, while few of them support linux environment as well.. Hence, you need to take a call based on the computer you want to operate with.

Other Printer Features

The loading of the design is also an important consideration. All the printers can print when connected to the desktop software. Some of the printers can print untethered via USB flash drive. Fewer printers like makerbot 2 offer an option to print over Wi-Fi. Some printers like ultimaker 2 may not work over Wi-Fi currently but have that provision so that you can upgrade later.

Many printers also have LCD display and even touch screen options to control the bed leveling, nozzle, filament and 3d design loading. LCD display can improve your interaction with your 3D printer, with more control on settings and easy navigation. Features like filament left, time estimated for printing etc will help you to use the printer better.

Keep an eye on the accessories included as they make your life easier, reducing the need to run round for small parts. Typical accessories offered include USB cables, power supplies, tools for cleaning and maintenance, filament cartridges etc.

Print Speed

There are different speed parameters that you can have a look at while executing your print. They are:

a) print speed–how fast the toolhead moves when it’s extruding the plastic,

b) travel speed – how fast the toolhead moves when it’s moving between printing areas in vaccum; without laying down plastic

c) Z axis speed

d) Bottom layer speed – to control adhesion related problems.

The first two speeds are more machine level capabilities while the next two speeds are controlled from the software.

While buying your machine your first priority speed parameter will be the print speed. You should realize that print speed and quality have an inverse relationship. Though not a thumb rule, faster speed will mean lower quality. However, some printers can be tuned to print quicker and without loosing quality. 3D printers that are well known for the speed are the the Ultimaker and the TrinityOne Aluminatus Pro, both having a speed of around 400 mm/s. You can even get many firmware with the help of which you can achieve higher printing speed. For example, the Makerbot Replicator’s official print speed is 40 mm/s, but the speed can accelerate up to 80 mm/s without a decrease in print quality if a firmware is added to the machine.

Output Quality

Printer resolution is also a very important parameter that determines the output quality. Layer height or resolution, is the vertical size of each extruded layer of filament. The smaller the layer height, the higher the resolution and the finer are the details. Also, the higher the resolution of the print, the more time it takes to finish the print. So, choose a printer which can print with very small layer heights and can also support a range of resolutions, so that you have an option to select lower resolutions for prints where you do not require very high quality. Among FDM printers, Ultimaker 2 can support a layer resolution of 20 microns, while Makerbot Replicator 2 and Cube can give a resolution of 100 microns (0.1mm) and 70 microns respectively. To give an idea, a common piece of paper has a thickness of 0.1mm. But the FDM machines cannot match the resolution possible by the more expensive SLA machines.

Another parameter related to resolution is the Printer tolerance, which refers to the accuracy with which a printer can extrude the filament. A smaller tolerance indicates a more precise print.

Community & Support

Irrespective of your expertise in 3D printing, you will definitely need the support of others to get great output from your 3D printers. Once you start your adventures with your dream machine, Blogs and forums are will prove extremely useful on matters ranging from filaments to extruders, software to hardware. These forums are a hub for exchanging ideas and life-saving hacks. Hence it is important to have a vibrant community discussing about the problems/ issues with your printer.

Do not forget to check if a warranty is provided by the company. Many 3D printing companies do not offer warranties just yet. Also, check the support offered by the manufacturers. Though Email and phone based support are the most popular methods, a few companies are going a step further and offering live chat or Skype based support. Some companies engage their customers through blogs and forums.

If you’ve gone through this article in entirety, we assume that you are ready go to the next articles in the series, which will delve on Printer categorization and Printer Comparision. If you are confused with the terminology, you can have a glance at this article to look at the basics.