On Monday, New Balance announced the limited commercial availability of running shoe with a 3D printed midsole, marking the first time the general public is able to get its feet in a pair. The Boston-based sporting goods manufacturer will release only 44 pairs of the Zante Generate shoe on Friday, April 15 at 09:00 am at the New Balance Experience Store on Boylston Street in Boston.

The shoe sells for $400, twice the rate of the most expensive shoes available in the market now. “Cost is still one of the barriers to mass production” explains New Balance Global PR Manager Mary Lawton. New Balance is using Selective Layer Sintering (SLS) technology to print the in-sole.

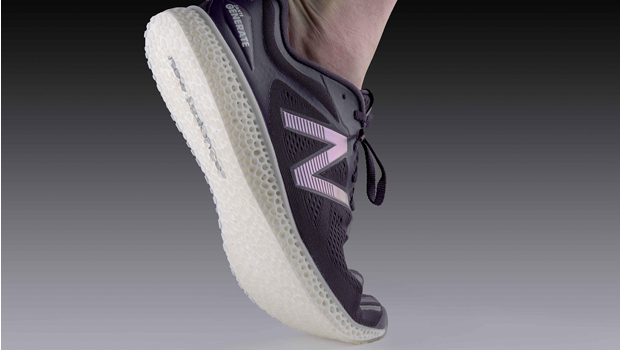

The Zante Generate features the same engineered-mesh upper found on the Fresh Foam Zante v2, a lightweight trainer, but in place of that shoe’s springy midsole foam, the Generate gets a full-length cushioning layer filled with bubbles or cells. These hollow spaces are what actually compress to reduce impact. Beneath that is a heel-to-toe clear rubber outsole for traction and durability.

The advantage in using 3D printing technology is really a matter of efficiency, saving time and money in the development process. In a traditional model, it takes about a month to build the injection molds that create the parts.

“By eliminating molds, we are able to save an enormous amount of time in prototyping,” said Katherine Petrecca, New Balance’s General Manager of Studio Innovation. “Printing also provides the flexibility to easily produce multiple designs at the same time. We can print over a dozen different midsole designs per day in one machine. This allows us to easily test multiple concepts against each other rather than follow the traditional, iterative testing process.”

Not just New Balance, many other shoe companies also started using 3D printing technology to manufacture shoes. Nike recently revealed a track spike designed for Allyson Felix, which underwent more than 30 iterations thanks to 3D printing. Adidas announced its Futurecraft 3D project last fall, while Under Armour turned out a training shoe for gym-goers called Architech last month.

Aside from the speed of developing prototypes, 3D printing offers some advantages over the old molded process. It allows the fit and cushioning to be customized to the wearer, and it offers the manufacturer the ability to vary the amount of cushioning throughout the shoe. “We can control the size and density of cells, and also the thickness of walls in individual areas, to deliver different properties within one part,” Petrecca said.

New Balance’s new midsoles represent a real breakthrough in balancing flexibility, strength, weight and durability in 3D printing. Previous models have tended to be rigid or heavy and not really suitable for walking or jogging. Given the limitations of cost and material, we believe it takes some more time before we all shall walk around in 3D printed kicks.