Oil and gas extractions lead to the availability of natural gas consists largely of methane, which is volatile and gets lost during the processing stages causing harm to the environment and also lead to the loss of usable energy. Storing this gas is a tedious and expensive affair, and requires complex technologies at a vast scale.

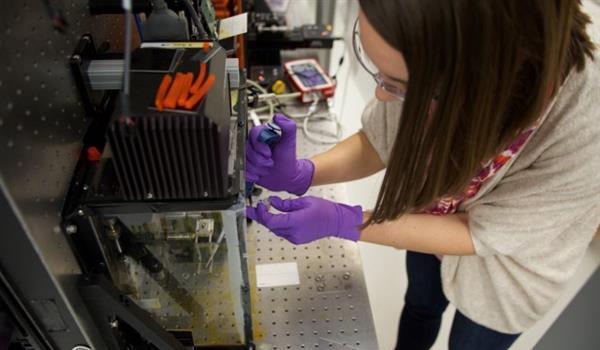

The 3D printed polymer created using a micro stereolithography 3D printer by scientists at LLNL University can be used to convert methane to methanol and save on the leaking methane in the transport pipelines. Moreover, it can be done at a much smaller scale and at low costs.

The 3D printed reactors are embedded with enzymes and can be used for a wide variety of applications like liquid gas reactions. The catalyst methane monooxygenese (MMO) is used to convert methane to methanol in normal conditions. Methanotrops are the methane-eating bacteria that require energy for sustenance and metabolic activities. Therefore, researchers separated these enzymes from the organisms to create more stable reactions.

The bio-reactors which were incapable of gas-liquid reactions could now be used for bigger output and utility by printing enzymes into a strong polymer structure.

These 3D polymers can be also reused and are capable of producing better output by utilizing a much lower amount of energy.

Source: 3ders.org