Day: March 2, 2017

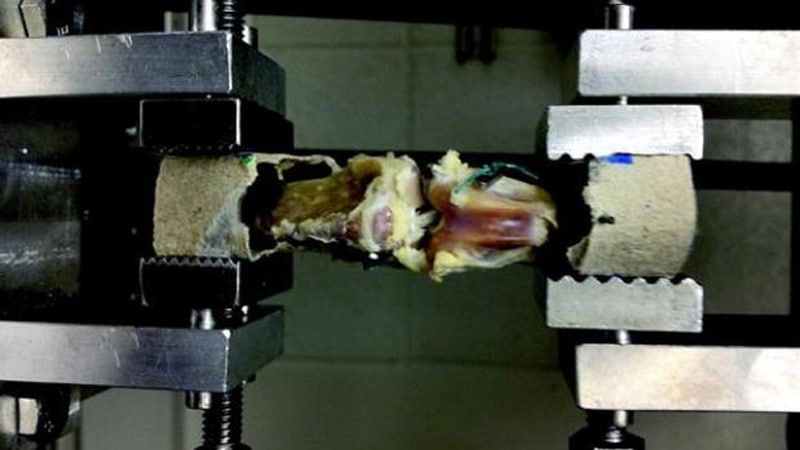

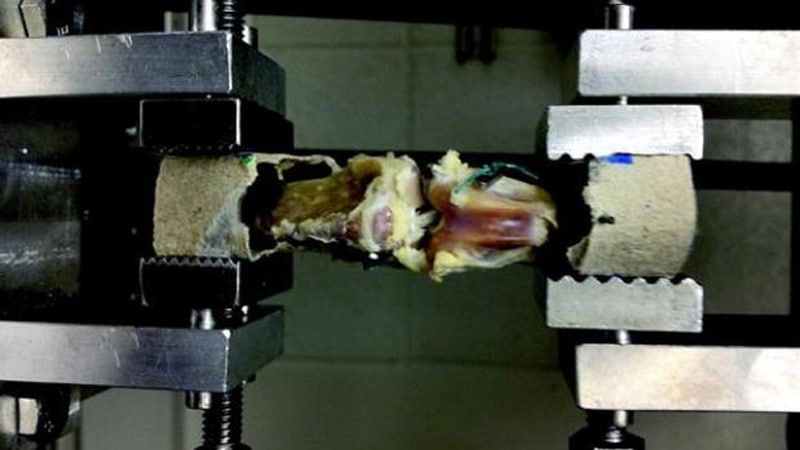

University of Tasmania Prof receives $630k as grant for his contribution to 3D printing

March 2, 2017

No Comments

Read More »

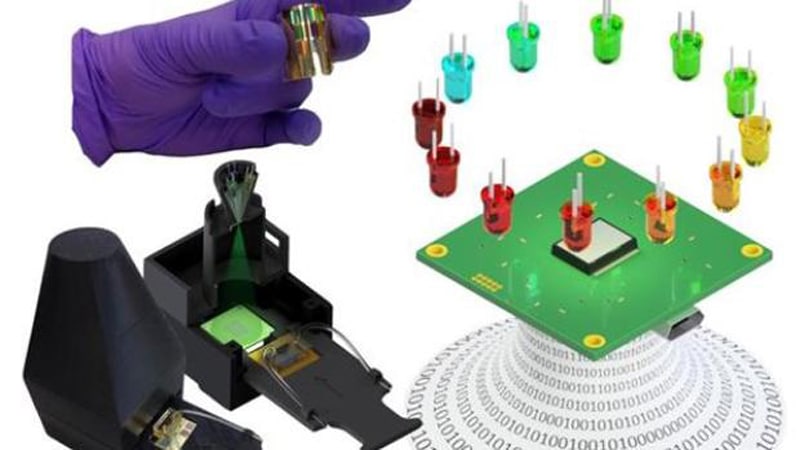

Researchers at UCLA develop medical sensors using machine learning and 3D printing

March 2, 2017

No Comments

Read More »