dimension inspection

- THINK3D provides detailed inspection of both 2D & 3D providing a full range of easy-to-understand reporting. The GOM measurement systems used by our team deliver the full-field scan data and sufficient resolution needed for genuine full-surface inspection, allowing the delivery of complete surface color-deviation maps, GD&T inspection back to drawing FAI and LAI and trend analysis across multiple-part inspection.

Dimensional Inspection Services

We use our expertise and precision measuring equipment to provide actual measurements of your parts or fixtures compared to drawing, CAD model or customer requested standards

Quick Online Quote

Upload files in Get Quote section and get quote within 4 hrs

Technical Competency

Technically qualified team in various mfg. technologies

Competitive Pricing

Highly competitive price and bulk discounts also available

NDA & IP Protection

All designs and data are kept in highly secure private server

Overview

- Length, width, and height.

- Angles and perpendicularity.

- Roundness, flatness, and other geometric characteristics.

- Position.

- Shape profiles.

- Surface characteristics.

- Edge sharpness.

- Thickness and uniformity.

It’s critical to have viable and reliable means of accurately verifying your manufactured products and manufacturing processes. One of the primary ways to accomplish this is via an in-depth evaluation of the first piece from your production run — also called first article inspection. We take great care in comparing the actual condition of manufactured parts, components, tooling and dies to the nominal condition as expressed in 2D drawings, 3D Models,

Applications

- First Article Inspection: Element provides fast, accurate 1st article inspection and verification of your design and manufacturing processes, helping you maintain an aggressive time-to-market plan.

- Reverse Engineering: Element experts can take design models or new, modified or undocumented components and generate the engineering data files needed for precision reproduction.

- Mold Qualifications: Fragile or small parts are no problem for Element. Using special techniques and materials, our experienced inspection professionals are able to quickly provide accurate dimensions under the most adverse design conditions without destroying your part

- Process Capabilities: Studies In today’s competitive market, you need to continually monitor and improve your processes and services to meet your customers’ needs. Element offers the expertise, analysis, tools and data to help you develop a system that ensures continual improvement in quality and productivity.

Methodologies

In general, when dimensional measurement is required, the results must be both accurate and precise. Although multiple techniques and countless applications exist, there are four main categories of dimensional inspection.

First Article Inspection:

Implementing a manufacturing process requires extreme attention to detail, especially if the process is new or if the equipment has been specially designed. First article inspection is required to ensure that the equipment was properly installed and calibrated, and to verify the manufacturing process. Dimensional measurement is used to compare the first objects from the manufacturing line to 3D CAD models, engineering drawings with tolerances, and/or other specifications.

Quality Control:

When objects coming off a manufacturing line must meet certain quality standards, measurement equipment is used to confirm that the dimensions fall within the required tolerance levels. In some cases, when the tolerance levels are more rigorous, each object is measured automatically. In other cases, batches might be spot-checked for quality.

Regulatory Compliance:

In industries for which regulatory compliance is necessary, dimensional measurement ensures that the required specifications are met. Regulatory bodies such as the FDA or FAA often have requirements regarding the dimensions of certain components.

High-Precision Engineering:

When creating a larger assembly from smaller parts, high precision is often required. If a minor flaw or inconsistency can impact an entire process, ensuring that such imperfections do not exist is critical.

The entire purpose of manufacturing is to create a process that is repeatable, scalable, and reliable. When successful, it results in lower production costs and lower pricing for the end user. However, precise, accurate measurements are required for any manufacturing line to be successful.

Dimensional inspection during the production process can help prevent costly errors such as:

- Flawed Batches: A production line that creates duplicate products requires precision setup and alignment. Errors in the production line can lead to entire batches of flawed goods, which can be quite expensive in both time and cost to correct the production error. Dimensional measurement is worth the investment to prevent these expensive mistakes.

- Defective parts: Using dimensional inspection as part of the quality control process for high-precision manufacturing ensures that each part meets the required specifications.

Quality control is essential for producing consistent products, but implementing dimensional measurement even earlier in the process can help prevent costly manufacturing errors that can lead to problems.

Softwares

Geomagics:

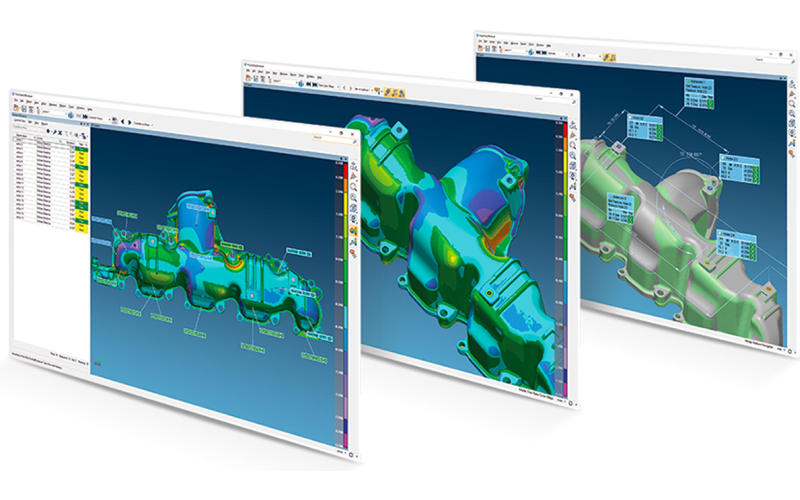

Geomagic® Control X™ is a professional 3D quality control and dimensional inspection software that lets you capture and process the data from 3D scanners and other portable devices to measure, understand, and communicate inspection results to ensure quality everywhere. Inspection isn’t just for metrology specialists. Geomagic Control X empowers everyone to measure, understand, and make decisions about their parts faster, more often, and more completely—from anywhere.

Polyworks:

PolyWorks|InspectorTM is a universal 3D dimensional analysis and quality control software solution to control tool or part dimensions, diagnose and prevent manufacturing and assembly issues, guide assembly building through real-time measurements, and oversee the quality of assembled products by using portable metrology devices and CNC CMMs.

Artec Studio:

Industry acclaimed software for professional 3D scanning and data processing. Artec Studio features the most advanced 3D data algorithms which give you high precision in your results, while at the same time make 3D scanning intuitive and user-friendly.

Hexagon Metrology:

PC-DMIS, Pro, CAD++, Touch PC-DMIS is the world’s most popular CMM software for the collection, evaluation, management and presentation of manufacturing data. Our software is standard on Hexagon Metrology measurement devices and is also available on a wide range of non-Hexagon equipment. Use it to fully leverage your manufacturing process and build truly lean systems. PC-DMIS Portable brings powerful metrology tools to the shop floor.

GOM Inspect:

GOM Inspect is a software for analyzing 3D measuring data from fringe projection or laser scanners, coordinate measurement machines (CMM) and other measuring systems. The GOM software is used in product development, quality control and production.

Case studies

Basic: Support Removal, Sanding, Smoothing

Add on: Primer, Coating/ Painting

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL

Frequently Asked Questions

ver the past two decades, 3D scanning has become a crucial tool in many manufacturers’ measurement and inspection arsenals. It’s an effective metrology technique that is trusted for its accuracy, reliability, speed, and ease of use.

3D measurement is a metrology process that uses different types of 3D measurement tools, such as 3D scanners, to collect 3D data from physical objects, such as their shapes, textures, geometries and colours. … 3D measurement is used in many different industries, such as: Aerospace. Transportation and automotive.

GOM Inspect is a free 3D inspection and mesh processing software for dimensional analysis of 3D point clouds and a viewer for data sets from the applications ATOS Professional, TRITOP Professional, GOM Inspect Professional and PONTOS Live.

Dimensional inspection is a big part of the manufacturing, and the end product of the process could be a finished product, a custom design component, and an R&D prototype. For the measurement of the equipment, dimensional inspection makes use of different values such as: The width, length or height.

A dimensional inspection report is an easy to read summary of the inspection. It will include a print with ballooned dimensions. This is usually a circled or squared number adjacent to each print dimension. The balloons should include each case of a multiple instance dimension referenced. So, a pattern of 5 holes will have a ballooned number for each of the five holes.

An image of the inspection set up with your part should be clearly shown to allow any repeat or future measurements. We find that having this included in the report answers many questions and improves the overall communication.

Accurate inspection dimensions are critical to the Manufacturing Engineer (ME). A large part of an ME’s job is to troubleshoot and correct issues that occur during manufacturing. Knowing the root cause of the problem is key to implementing a long-term solution and not having to fight the same issue again and again. Accurate and reliable dimensional information on the parts is critical to understand the baseline conditions. Use Think3D expertise to help satisfy these measurement needs.

Clients use our dimensional inspection services for numerous reasons. Many lack human resources, equipment resources or time resources. Some have unique capacity or capability needs we can meet. Others require a non-biased 3 rd party evaluation or need a discreet outside professional metrology service to assist with R&D or legal matters.

Satisfied inspection customers are found in all industries including military, medical, automotive, aerospace and appliance. Our experience measuring parts spans most manufacturing processes including injection molding, casting, CNC machining, forging, extruding, stamping and forming.

There are three primary types of dimensional inspection equipment: precision hand tools, contact sensor systems, and noncontact sensor systems.

Here is where knowledge and experience are paramount. Just making the measurement of certain dimensions possible is difficult enough, let alone making the measurements feasible. For every object imaginable, from a nanoscale surface to a rocket engine, there are numerous measurement opportunities. There are also multiple ways to execute each measurement technique, and multiple devices and manufacturers from which to choose.

When investing in dimensional inspection equipment, the primary objectives are to find a device or system that:

Allows for the inspection to be performed correctly, accurately and precisely.

Allows for the inspection to be performed as quickly as possible.

Serves the functions you require.

Is reliable and has a long lifetime.

Can be easily operated and maintained.

Fits the budget