3D Printing services

- THINK3D offers an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you on demand in as fast as a day. We are your one-stop-shop for accurate, precise, custom 3D printed parts at an affordable price.

Additive Manufacturing Services

Turn your ideas to reality with our full fledged 3D Printing, CNC Machining, Casting & Molding service capabilities. Our facility is equipped with entire range of 3D Printing technologies, 10 CNC Machines, 2 Injection Molding Machines and have a passionate team to serve you.

Quick Online Quote

Upload files in Get Quote section and get quote within 4 hrs

Technical Competency

Technically qualified team in various mfg. technologies

Competitive Pricing

Highly competitive price and bulk discounts also available

NDA & IP Protection

All designs and data are kept in highly secure private server

We have in-house

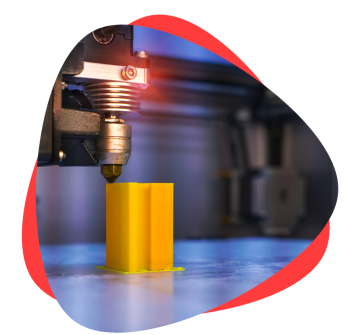

Fused Deposition Modeling

Fused Deposition Modeling (FDM) is a commonly used 3D printing technology and is famous for its possibility to print large parts, accuracy, wider material selection and competitive cost. With more than 15 FDM 3D Printers of various brands present in-house, think3D offers the best quality FDM 3D Printing service with least turn around time. We also offer various post-processing services too.

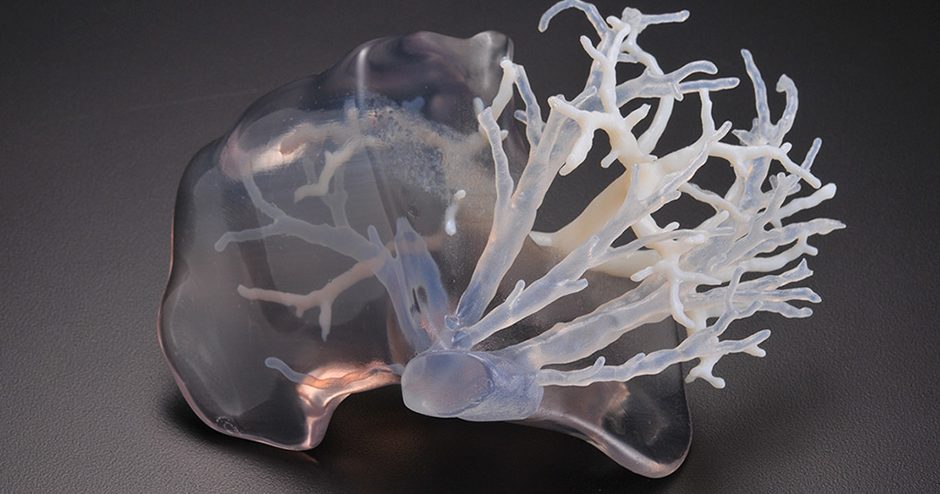

Stereolithography

Stereolithography(SLA) is a powerful 3D printing technology that give extremely accurate parts which can be used for direct end-use and rapid prototyping.think3D has 6 SLA / DLP / MJF machines of various resolutions and build volumes in-house. With these machines, think3D can offer some of the best resin based 3D Printing solutions to customers across various industries.

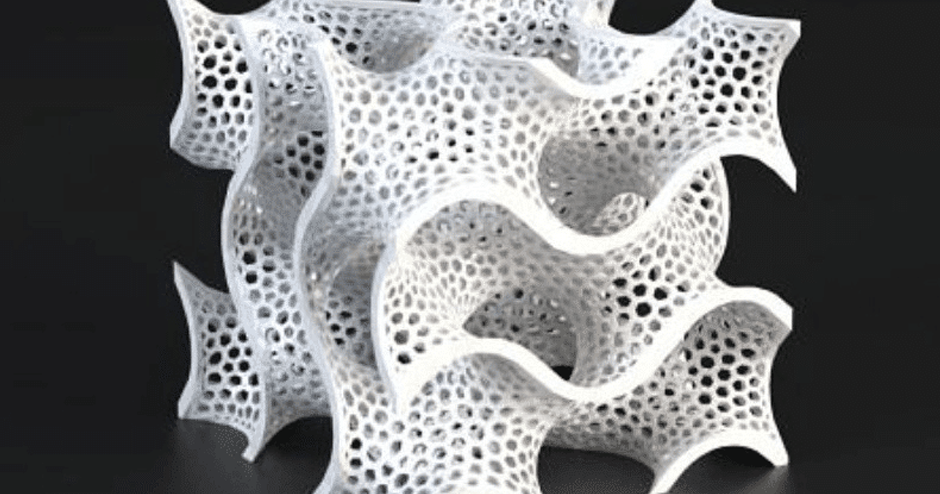

Selective Laser Sintering

Selective Laser Sintering (SLS) is one of the famous 3D printing technology which gives highly accurate and durable end use products. It is also one of the most inexpensive for industrial 3D printing as it can build parts in bulk without the support structure requirement. think3D has one EOS P110 machine in-house. We have the lowest turn-around time and highly competitive price in the market for powder based 3D Printing services.

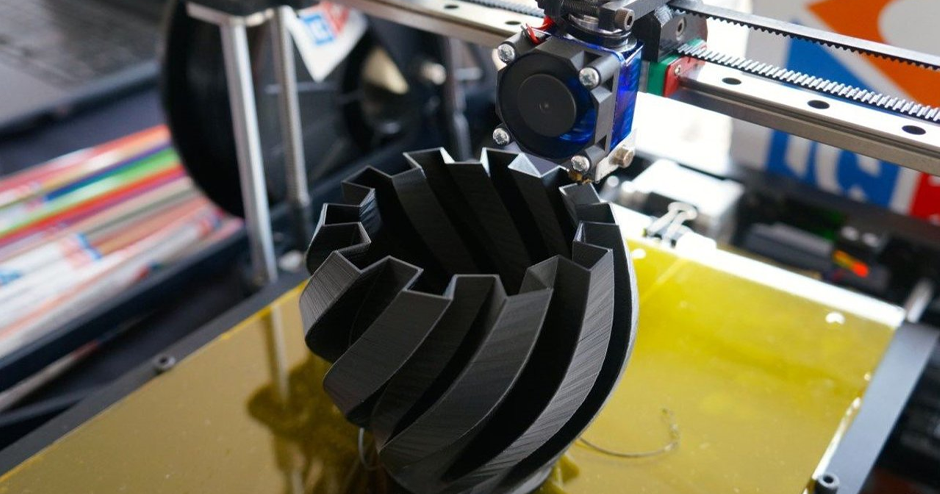

Direct Metal Laser Sintering

Direct Metal Laser Sintering(DMLS) is a metal 3D printing technology which selectively fuses fine metal powders. think3D has one EOS M290 machine in-house to offer various metal additive manufacturing service. We can 3D Print various metals like Chromium Cobalt, Tool Steel, Maraging Steel, Aluminium

Color Jet Printing

Color Jet Printing (CJP) is the most exciting 3D printing technology as the parts printed are like real life models. think3D has one Projet 660 PRO 3D Printer from 3D Systems. We can offer various full color miniatures through this machine. We have the lowest price and quickest turn around time in the market.

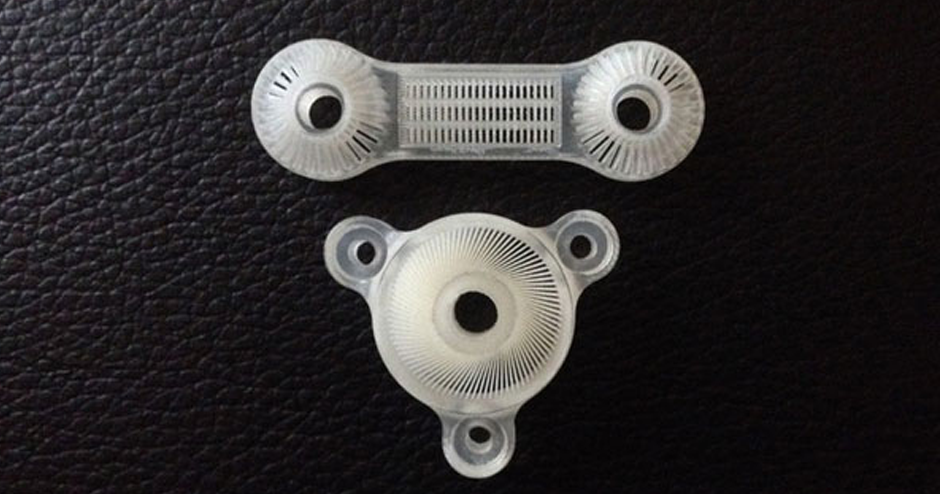

Poly Jet Printing

Poly Jet Printing (PJP) is a rigid photopolymer 3D printing technology that produces high-detailed models. This process injects liquid photopolymer material and cures it layer by layer using UV light. Polyjet is known for its speed and excellent surface finish. It is also capable of printing in multiple materials at once. think3D has one PJP machine in-house to offer the unique ability to print parts of multiple materials and colors, with different mechanical or physical properties.

Multi Jet Printing

Multi Jet Printing(MJP) is a 3D printing technology used to build parts, patterns, and molds with fine feature detail to address a wide range of applications. think3D has one MJP machine in-house to produces micro-detail wax patterns with outstanding surface quality and extremely fine features, ideal for intricate direct investment casting applications, such as jewelry.

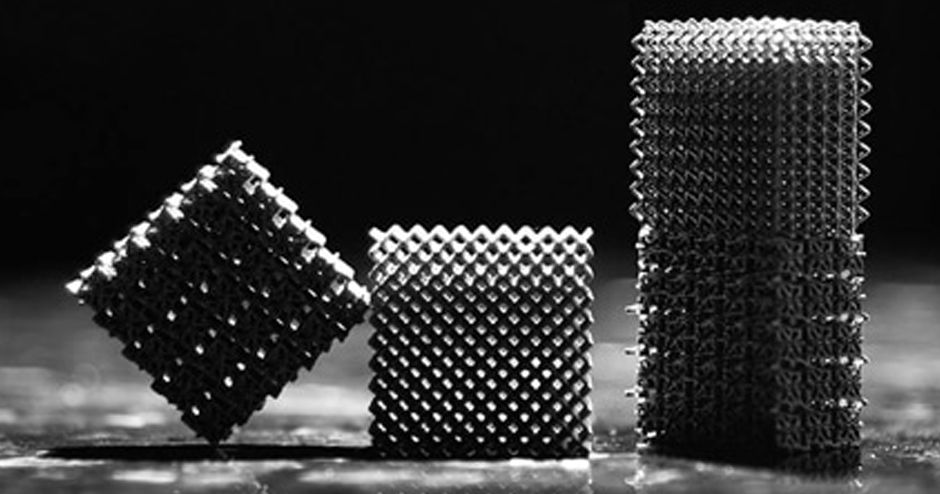

Multi Jet Fusion

Multi Jet Fusion (MJF) is a powerful technology that produces high accurate and durable parts at fast speeds when compared to other powder bed fusion technologies. think3D has one MJF machine in-house for models which require crisp textures, surface details or labels. It’s also a good material for highly complex parts with lattices and hinges.

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL

Applications Of 3D Printing

Turn your ideas to reality with our full fledged service capabilities. No restrictions on creativity!

Few Case Studies

What is Design For Manufacturing (DFM)

3D Printing of Silicon

Frequently Asked Questions

3D printing is an essential tool for accelerating the prototyping process. However, its applications stretch well beyond prototyping to other facets of the product lifecycle.

• Manufacturing – Design freedom and economically viable low-to-mid-volume production enable new possibilities for product design and operational improvement. Applied in combination, these two capabilities have the potential to transform decades-old supply chains and business models.

• Tooling – 3D printed tooling advantages include on-demand production, customization, digitization of designs and unrestrained design flexibility. This cuts out costly suppliers, compresses lead times, enables digital warehousing and accelerates manufacturing floor productivity.

• Sales and Retail – 3D printing gives retailers the ability to innovate, delivering highly customized, on-demand products and new experiences such as “co-designed” items developed in conjunction with the customers.

• Aftermarket Supply – Businesses that embrace 3D printing for spare and replacement parts can replace warehouses of spare parts with 3D printers or a contract 3D printing service bureau to produce parts on a just-in-time basis.

3D printing accelerates the process by reducing the time and cost associated with prototyping and refining the design. Many more 3D printed prototypes can be produced in the time needed to mold or machine them and for much less cost. Highly realistic prototypes printed on full-color multimaterial printers look like the final product, cultivating faster and better decisions.

3D printing gives designers the capability to drastically shorten the design process compared to traditional methods of hand-modeling or outsourcing to model shops.

Keep the design process entirely in-house. With 3D printing, designers gain full control over the design process. Creating models in-house saves the time associated with outsourcing. More timeline flexibility empowers designers to try new ideas and iterate often, resulting in better products that stand out.

Prototype faster and smarter. Outsourcing is often too expensive and time-consuming to allow iteration of more detailed prototypes, especially models that incorporate CMF (color-material-finish). The speed and streamlined workflow of 3D printing gives designers the freedom to create dozens of detailed prototypes while reducing the time to arrive at the optimal design.

Create beautiful, highly detailed models. With full-color, multimaterial printing, designers can create prototypes that look, feel, and even function like the real thing in just a few hours. The ability to assess the color, texture, and ergonomics of a product means better feedback and faster approval from clients.

3D printing is not a wholesale replacement for existing manufacturing methods like molding and machining. Its benefit lies in supplementing these other technologies at points where they can’t compete. For example, 3D printing’s additive nature is able to make structures that aren’t possible with machining or molding. It also makes low- to mid-volume production economically viable because there’s no need for the tooling investment. Similarly, it’s much faster to get started, which is why GM turned to 3D printing to retool its production line to produce ventilators in the pandemic. In short, 3D printing is another tool in the toolbox, but one that offers key benefits over traditional manufacturing practices when used strategically.

Contracting with a service bureau to make your 3D printed parts is a good way to get introduced to the benefits of the technology. You gain the expertise and insight of a 3D printing specialist who can possibly guide you in optimizing the use of the technology for your specific purposes. Your out-of-pocket expenses are usually lower initially since you avoid the up-front expense associated with a printer purchase.

Additive manufacturing shows promise for the defense, energy, aerospace, medical and commercial sectors. Its alternative approach to machining, forging, molding and casting makes it a good choice for rapidly making highly customized parts. The technology also shows promise for creating parts on site, such as at forward-stationed military bases. Because of its potential, many companies are using the technology to get themselves into a position to use it. The growing field of companies using the technology includes makers of machine parts and novelty items.

We’ve been in the business of helping customers solve problems for over 8 years with our 3D printing solutions. We can help you determine what technology is right for your application, whether a printer or a service bureau is more appropriate, as well as answer any questions you might have.

Yes, lots of different companies across a range of industries use additive manufacturing, including the medical industry, aerospace and more. Additive manufacturing is particularly useful for making complex or bespoke parts – whether for a new application or to replace an old part that may no longer be available.

- Freedom to design parts and sub-assemblies for the design, not for the manufacturing processes (DFM*)

- Have inventory on demand for both production and spare parts

- Eliminate costs of inventory and the time lag of supply chains

And!

- Gain the ability to quickly prototype with the same process with which you will manufacture — true rapid prototypes!

46 replies on “3D Printing”

I would like to make a 3d print of Che Guevara with a size of 6 to 7 feet. I don’t have any model with me. How much will this cost me to produce the 3d model

Thank you for contacting us for your prototyping/ 3D printing requirements. Our engineers will get back to you within 24 hours.

Hello sir , Hope you are doing great.

We need a Disc Brake with and without Radial Grooves, it is usually provided for maximum heat dissipation, It is a comparative study with and without radial grooves developed using 3D printed Disc.

Hope you help in this regard so that we can start working on this. i will be sending the CAD files which will be in SOLID WORKS.

we r looking for the disk Brake that must b 3D printed with Aluminium or titanium alloy not the conventional brake available in the market, The disc is having radial slots for maximum heat dissipation which is the key feature of our disc.

Technology must mentioned in the QUOTE as Direct Metal Laser Sintering or Metal 3D Printing.

Why titanium or Aluminium alloy we need to test this on test rig for extracting thermal characteristic with and without radial grooves

Please help me in this regard at the earliest. Can u check the dimensions on Toyota-COROLLA website for the same dimensions and give quotations for the disc.

Thank you for contacting us. Soon respective person will get back to you with the details.

I would like to know about the price for the type of metals and amount of metals used for simple component ( need for my main project )

Hello. Can I get a bust made of my late father? Say around 1ft height. What will be the cheapest and easy to maintain and long lasting material.

Hello, We will be happy to help with your requirement. The respective person will get back to you with the required information.

Hello,

We are looking after for rapid prototype for our various ceiling fans models. Kindly contact us so that we can talk in detail.

Thanks for contacting us. You will be contacted by our engineer within 24 hrs.

Hi, I have a 3D model that I need to get printed. Would you be able to design the supports, etc. in addition to 3D printing? Do you print in ABS? Also, do you deliver the products that you print?

Thank you for reaching out to think3D. We do provide design support, print with ABS material and ship throughout India.

Hi, I need a propeller guard for my done. Can it be designed by you and printed. I need it within one day. Thank you.

Thank you for considering us for your designing & 3D Printing requirements. Please share the inputs you have for propeller guard. Our team will get in touch and guide you on the next steps.

Need to print a 3D material with Poly Lactic Acid ,Nano Hydroxyapatite and Zirconia nano particles.

Thank you for considering us for your prototyping/ 3D Printing requirements. Materials we do offer 3d printing services with are ABS, PLA, PMMA, HIPS and flexible can be done in FDM technology. Nylon(PA 12) can be done in SLS process and Resin material and translucent can be done in SLA process, rubber material and silicon can be done in the vacuumcasting process, resin material can be done in poly jet process. We can also provide services with metal printing also.

Am currently designing an urban scale project. Which includes more cantilivers and rooms with large slabs does this.. messup the interior room space with support material ? Do i need to make different models to make printing easy or can i directly export my whole sketchup model to STL ? Please contact me and i need a quotation.

Dear Mr.Naren, thanks for contacting think3D. Kindly drop an email to info@think3d.in regarding this and with your contact details in it, so that we can arrange a call for you from the technical person who can address you with all the details. For any other queries feel free to reach us on 8142896564.

Hello,

I am working on corrugated horn antenna and circular waveguide.

I want to fabricate the corrugated horn antenna and a corrugated circular waveguide in aluminium or copper for research purpose.

my lowest dimension is 0.1 mm groove width of the corrugation.

can you fabricate these devices?

Thank you for reaching out think3D for your prototyping requirement. Our team shall get back to you with more details

Hello,I wanted to use your rapid prototyping service.So can I know what are the payment options available like net banking,debit card???

Thank you for considering us for your prototyping/ 3D printing requirements.

We have received your request and our team shall get back to you with the complete details.

Thank you

I wish to print my model but didn’t know how to proceed for it process.

Greetings from think3D.

Please share your design files to info@think3d.in so that we shall give you the quotation for the same.

The acceptable file formats are STL/OBJ.

We also accept STP/IGS formats we have a design team to assist you.

Thank you.

Hello

I would like to get prototypes of titanium (including alloying metals impurities) with different combinations of printing parameters. let me know whether it is possible or not?

Thank you.

Greetings from think3D.

We have forwarded your requirement to the concerned department they shall get back to you at the earliest.

Thank you.

I would like to print a case for my Asus tinker board but I don’t know how to make a file or et cetera for it could please help me I only have a ✋ made rough wooden model of it

Greetings from think3D.

We have forwarded your request to the concerned department they shall get back to you at the earliest.

Thank you.

Hello,

What is the minimum dimension you can print?

Thanks

Greetings from think3D.

The minimum thickness of the wall should be 1 mm.

Thank you.

Hi , I am looking for 3D design for a product. Please contact me

Dear Mr.Masthan, thanks for contacting think3D. Kindly drop a mail to info@think3d.in with some images of the product attached so that we can proceed further.

Hi There, I want to 3D print the stopper of Money box that I got for my kid from a trip abroad, as we have lost it.

I do have a prototype a hard copy (of the stopper) and will need to print another copy of it, on a plastic or like material will that be possible?

And what will be cost involved ?

Dear Bikash Mishra, thanks for contacting think3D. Kindly drop a mail to info@think3d.in with the design files attached of the stopper so that we can get back to you with a quote or else you can send the image of the stopper if you have it so that our design team can get back to you.

I would like to have a 3d print statue of 1 feet height of my mother how much it costs and time. Kindly provide the details

Dear Mr. Arun, thanks for contacting think3D. Kindly drop a mail to info@think3d.in with the images attached for the reference, so that we can get back to you with the quotation.

Hi

I need a water tank to fit in the spare wheel space in my car.

Dear Mr.Asher, thanks for contacting think3D. kindly drop a mail regarding this with some images or 3d design files attached for the reference, so that we can get back to you with feasibility. For any other queries feel free to reach us on 8142896564.

Dear think3D,

I want to ask whether fountain pen body and ink mechanism can be made through 3D printing as per different calligraphy nibs.And what would be its approximate costs.

Regards

Dear Mr.Harish, thanks for contacting think3D. We are sorry to inform you that we couldn’t fulfill your requirement, as we are not into it. For any other queries feel free to reach us on 8142896564.

I want a metal 3D proto for which i can share the 3D model. Would it be possible to make it either in Cooper or Brass?

Dear Mr.Tushar, thanks for contacting think3D. Kindly share the 3D design files of the part on the link below, so that we can let you know the feasibility. For any other queries feel free to reach us on 8142896564.

https://www.think3d.in/placeorder/

I am working on a G+ 4 storeyed Residential Building (total built-up area around 8000 sq.ft.) adjacent to a Hospital Building. I need a detailed 3d model of the Residential Building and a sketchy block print of the adjacent Hospital Building. Please contact me.

Thank you for reaching out to us. Please send an email to info@think3d.in and our team shall reach out to you with further information.

Hi, Looking for color changing 3d printing service. Please reach out at 9970347400

Hi, I fear we don’t offer such color changing 3D Printing service. If you need regular FDM, SLA, SLS, MJF, DMLS 3D Printing services, please do reach out to us.

Do you print spare parts for cars.