MOLDING & CASTING

- At THINK3D, we have injection molding and vacuum casting machines in-house offering various injection molding & casting services.

INJECTION MOLDING SERVICES

Turn your ideas to reality with our full fledged 3D Printing, CNC Machining & Molding service capabilities. Our facility is equipped with entire range of 3D Printing technologies, 10 CNC Machines, 2 Injection Molding Machines. We offer services in wide variety of materials and provide free design analysis with every quote. On top, we have a highly passionate team to serve you.

Quick Online Quote

Upload files in Get Quote section and get quote within 4 hrs

Technical Competency

Technically qualified team in various mfg. technologies

Competitive Pricing

Highly competitive price and bulk discounts also available

NDA & IP Protection

All designs and data are kept in highly secure private server

We offer in-house

Injection Molding

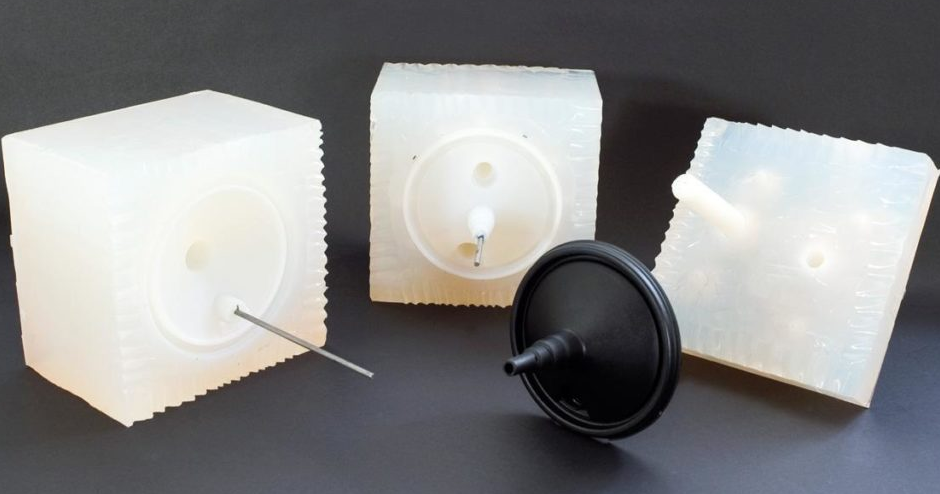

Vacuum Casting

THINK3D offers high quality industrial casting services in Vacuum Casting machine. Vacuum casting is a casting process for elastomers using a vacuum to draw the liquid material into the mold. With 3D Printing, CNC Machining, Vacuum Casting, Injection Molding services all at one place, we are a truly one-stop shop for your manufacturing needs.

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL

Applications Of MACHINING & MOLDING

Turn your ideas to reality with our full fledged service capabilities. No restrictions on creativity!

Few Case Studies

What is Design For Manufacturing (DFM)

3D Printing of Silicon

Frequently Asked Questions

- Electronics Parts Manufacturing.

- Engraving Machine Applications.

- Machining Composites.

- 5 Axis Machining.

- Dental Milling Applications.

- Micro Hole Drilling.

- Machining Aluminum.

- Machining Plastics.

There are basically five different types of CNC machines:

- CNC Plasma Cutting Machine.

- CNC Laser Cutting Machine.

- CNC Milling Machine.

- CNC Router Machine.

- CNC Lathe Machine.

We offer CNC Routing, EDM finishing, laser cutting services