cad modeling

- We offer a range of CAD and 3D modelling services. Our technical team have a wealth of knowledge and experience to undertake any 3D modelling or drafting projects. we use experienced and degreed engineers to create well thought out CAD modeling services that are designed to help your company succeed.

CAD Modelling services

One fundamental reason to choose think3D over other CAD modeling services is our expertise in CAD modeling. We have a highly specialized team that can delivery high quality CAD models within the stipulated time period. As we work with customers from various industries, we have clear idea of customer requirement and deliver output accordingly.

Quick Online Quote

Upload files in Get Quote section and get quote within 4 hrs

Technical Competency

Technically qualified team in various mfg. technologies

Competitive Pricing

Highly competitive price and bulk discounts also available

NDA & IP Protection

All designs and data are kept in highly secure private server

Overview

3D modeling or CAD (Computer Aided Design) allows engineers and designers to build realistic computer models of parts and assemblies. These models can be then 3D Printed or CNC machined as well as used to run complex simulations. A wide range of parameters can be simulated such as strength or temperature resistance before any physical models have been created, enabling a much faster and cheaper workflow.

Solid modeling creates solid 3d models as if they are actual parts, with a logical workflow which is similar to the processes which would be used to manufacture the part. Some of these operations include extruding, drilling and threading operations. Solid models can intersect, join and subtract objects from one another to create the desired part.

Another advantage of solid modeling is that it is usually parametric, meaning that changes, or parameters are saved at every stage of the modeling processes and can be edited at any time during the design. This is very useful as it allows features of the model to be quickly modified without needing to create the part from scratch.

Assembly modeling is also an important stage in solid modeling, allowing individual parts to be assembled together, forming complex models. Assemblies can be used to insert standard components such as fasteners or bearings, that have been downloaded directly from the manufacturers. Motion elements can also be applied to assemblies, allowing detailed motion analysis to be used to evaluate the mechanical performance of the design.

Surface modeling is usually used for more aesthetic features of a product. It is much easier to create more organic and free-form geometry using this type of CAD software. Many of the constraints found in solid modeling are not an issue with surface modeling, however, this comes at a cost of sometimes being less accurate.

As the name suggests surface modeling only contains surfaces of the part, with no solid interior. However, once the part has enough surfaces to close the part, it can be filled and then used for 3D printing. When developing designs using surface modeling, it can be hard to go back and make changes because usually it is not parametric.

Each type of modeling software has benefits and drawbacks, depending on the type of design being produced this needs to be considered. Sometimes using both solid and surface modeling is needed to combine the benefits of each.

Applications

- 2D drawings to 3D models conversions

- Concept visualisation

- 3D models preparation for production or prototype

- CAM or a 3D printer compatible input 3D models can be generated.

Methodologies

Drawing Philosophy :

Drawings should be laid out in an easy to understand format with proper notations and a clean look. To help ensure that our standards are met in our CAD drafting services, we use some of our other internal engineers to perform checking of these drawings.

Design :

Our product design knowledge and ability carries directly over to our CAD modeling service and drawing layout service. We have the ability to easily integrate our customer’s product-specific ideas into their 3D CAD design as well as make significant innovative contributions to the final product.

GD&T :

All of our engineers are certified in Geometric Dimensioning and Tolerancing (GD&T). Since each engineer is also trained and gains experience through our inspection service, we have gained practical knowledge in print interpretation and application of good GD&T practices in our modeling and drafting work.

Model and Drawing Checking :

Do you already have a design and drafting team and just need support checking their work? We also support that work. Often times, the CAD design cycle leaves little time for proper model and drawing checking.

software's

UG NX :

Siemens NX software is a flexible and powerful integrated solution that helps you deliver better products faster and more efficiently. NX delivers the next generation of design, simulation, and manufacturing solutions that enable companies to realize the value of the digital twin.

Supporting every aspect of product development, from concept design through engineering and manufacturing, NX gives you an integrated toolset that coordinates disciplines, preserves data integrity and design intent, and streamlines the entire process.

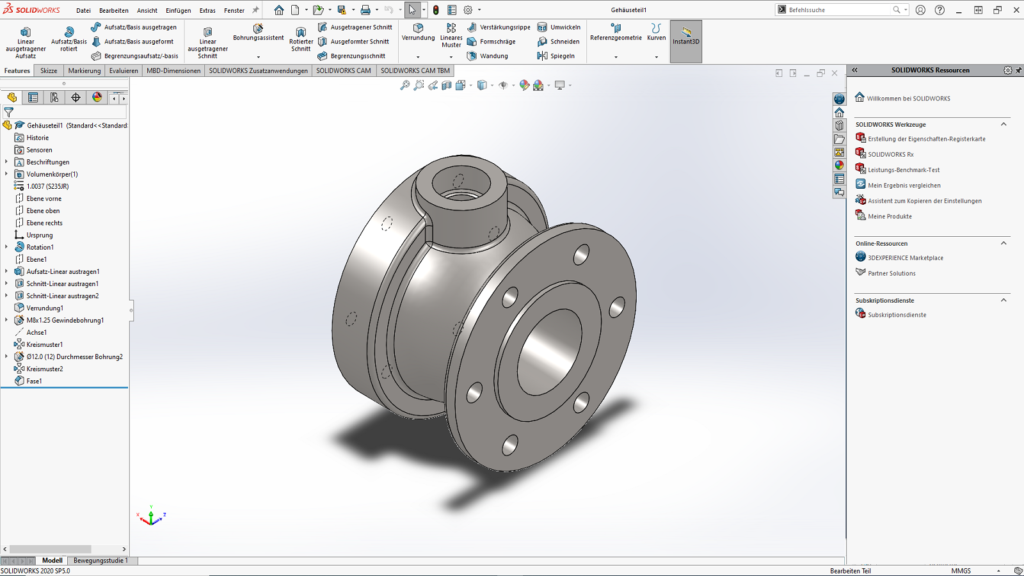

SolidWorks :

SOLIDWORKS 3D CAD has the most efficient and powerful CAD design collection available for product and part assembly designers. The SOLIDWORKS CAD suite of tools allows you to grow your business out of an intelligent, effortless SOLIDWORKS seed, so your organization can scale, flourish, and adapt to the 3D modeling changes for decades to come. Industry standard engineering software used for part and assembly modeling, includes simulation features as well as drawing and assembly tools.

AutoCad :

Autodesk AutoCAD, a software package for 2D and 3D CAD, has been used since 1982! AutoCAD is used across a wide range of industries, by architects, project managers, engineers, graphic designers, and many other professionals.

Case Studies

Basic: Support Removal, Sanding, Smoothing

Add on: Primer, Coating/ Painting

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL

Frequently Asked Questions

Fundamental driver for outsourcing CAD services is the same as that for any other business process outsourcing. Outsourcing is done if the company doesn’t have core competency in CAD services, if the company has an one-off requirement and doesn’t want a full time employee, if the company wants to bring down the cost by outsourcing non-core activities and focus only on core activities. Any of these reasons can propel the company to outsource CAD services. From our experience, outsourcing the CAD services will result in much better quality output and 30% – 40% lower cost to the company.

Hoping that you have decided to outsource you CAD modeling services, one fundamental reason to choose think3D over other CAD modeling services is our expertise in CAD modeling. We have a highly specialized team that can delivery high quality CAD models within the stipulated time period. As we work with customers from various industries, we have clear idea of customer requirement and deliver output accordingly.

Each project is very unique and requires varying timelines. Thus we can’t provide costing without knowing the customer requirement. Therefore for every project we provide a proposal for client’s approval. Projects are generally billed on a lump sum based on our estimation of the total number of hours it takes to finish the project.

For time being, we don’t have plan to provide on-site CAD technicians. Our competitive advantage lies in having a centralized services center where regular know-how transfer happens between teams. If you have any such requirement, just let us know. If it is a very long term assignment, we may consider it.

All export formats supported by Solidworks & NX can be accepted

Preferred formats are

.PRT

.STP

.IGES

Our email system can handle file up to 20Mb. If the size of the files exceeds this, an ftp site is available to aid in the transfer of files. Additionally, we use the Dropbox cloud based ftp system for fast efficient sharing of files.

This is a necessary step in the process and also creates the opportunity to work out the functional details of the design in the computer before building anything physically. All of the prototyping and manufacturing technologies we use are run off the digital file created in the 3D CAD software.

We understand our client’s concerns regarding confidentiality. All data provided by the client will be kept confidential and will be the property of the client. Our firm and staff agree that no information regarding the project will be disclosed to any third party, without the prior consent of the client. If requested by the client, we have no issues signing a non-disclosure agreement for any project.

Solidworks & NX

Yes, we will use your existing CAD background files.

One reply on “CAD Modeling”

Linear pattern