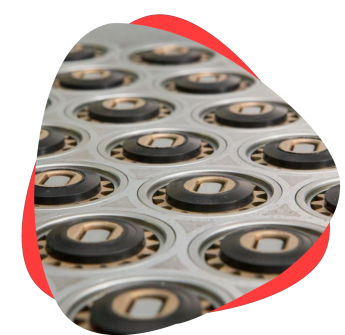

LIQUID SILICONE RUBBER (LSR)

- Liquid silicone rubber moulding is a thermoset process that mixes a two-component compound together, which is then heat cured in the mould with a platinum catalyst to produce a final LSR part.

About LSR Material

Liquid Silicone Rubber has excellent thermal, electrical, and chemical resistance properties, although it can be attacked by certain solvents such as gasoline or mineral spirits, which is why it can be used in high-temperature automotive applications but not for fuel lines. And it has low compression set—low permanent deformation when a force is applied and removed—making it ideal for elastomers. This allows for faster and most cost-effective tooling when compared to traditional steel moulds.

Since LSR is a thermosetting polymer, its moulded state is permanent—once it is set, it can’t be melted again like a thermoplastic. When the run is complete, parts (or the initial sample run) are boxed and shipped shortly thereafter.

Quick Overview

| Processes | Lead Time | Color | Tolerance | Price | Applications |

|---|---|---|---|---|---|

| Injection Molding | 20-30 Days | White & available in all major colors. | As low as +/- 0.08mm | Qty & Precision dependent | High strength, Good surface finish. |

Design Recommendations

| Services Name | Max Size | Min Size | Min Thickness | Undercuts | Radii Depth |

|---|---|---|---|---|---|

| For Molding | Max Part Size: 304mm x 203mm x 100mm | Min Hole size : 1 mm | Min Wall Thickness: 0.5 mm | Undercuts, such as those shown, can complicate and, in some cases, prevent part ejection, so eliminate them if possible. | Minimum draft angle of 0.5°, or up to 5°, for faces with medium textures |

Frequently Asked Questions

Transparent.

Biocompatibility

Durable

Chemical resistance

Temperature resistance

Yes, Liquid Silicone Rubber possesses a natural transparency, this attribute makes it possible to produce, colorful, custom, molded products.

Liquid Silicone Rubber has excellent insulating properties, which offer an appealing option for a host of electrical applications. Compared to conventional insulating material, silicone can perform in far higher and lower temperatures.

The injection molding of liquid silicone rubber involves a complex task that consists of numerous functional and structural factors the designer must address, including:

- The intended use of the part.

- How the part fits in an assembly.

- The loads the part will experience in use.

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL