CNC TURNING

- Our CNC turning process produces prototypes and end-use parts within 3 - 4 days. We use lathes and turnmill processes to manufacture parts from more than 30 engineering-grade plastics and metals.

CNC TURNING

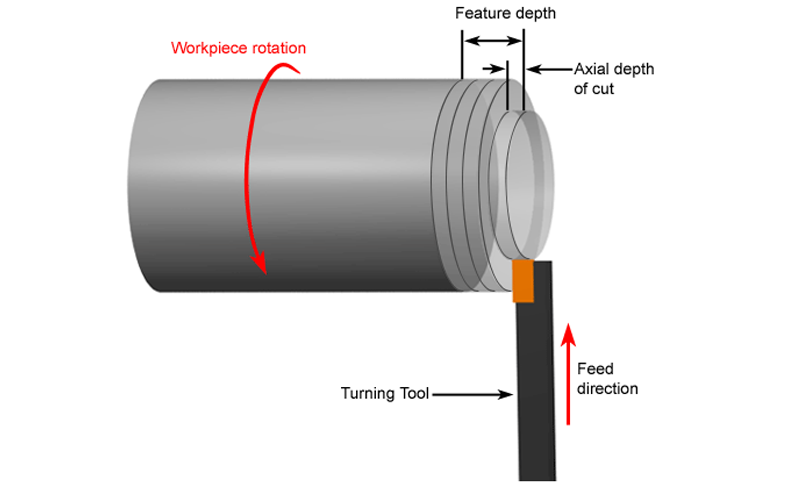

Our CNC turning process produces custom prototypes and end-use production parts in as fast as 1 day. We use a CNC lathe with live tooling so features like axial and radial holes, flats, grooves, and slots can be machined.

Quick Online Quote

Upload files in Get Quote section and get quote within 4 hrs

Technical Competency

Technically qualified team in various mfg. technologies

Competitive Pricing

Highly competitive price and bulk discounts also available

NDA & IP Protection

All designs and data are kept in highly secure private server

Overview

CNC turning is a subtractive manufacturing process that rotates a metal rod while a cutting tool is held against the stock to remove material and create final parts. Our CNC lathes are also equipped with live tooling that can machine flat features and holes into the workpiece. Outside diameter (OD) and inside diameter (ID) threading is also available.

Turned parts can then be left as-machined, with visible tool marks, or bead blasted. When the run is complete, parts are inspected, boxed and shipped shortly thereafter

Applications

- Functional prototypes & end use parts

- Parts with cylindrical features

- Parts with axial and radial holes, flats, grooves & slots

materials

PLA

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

ABS

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

PETG

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

Nylon

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

Poly Carbonate

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

Wood

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

Flexible

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

HIPS

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

PVA

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

specifications

Maximum Diameter: 300 mm

Minimum Diameter: 5 mm

Maximum Length: 400 mm

Minimum Length: 2 mm

Tolerance: 5 – 10 microns

Lead Time: Minimum 5 working days for despatch

Surface Finish: As per the drawing given

post processing

Basic: Deburring, Buffing, Tapping, Lapping, Sand Blasting

Anodizing: Anodizing is an electro-chemical process that converts metal surface into a decorative, durable, corrosion resistant anodic oxide finish.

Chrome Plating: Chrome plating helps protect parts from corrosion while adding electrical conductivity and the ability to paint the part. Steel and iron based metals require pretreating with zinc before applying chromate.

Spray Painting: Spray painting is a painting technique in which a device sprays coating material (paint, ink, varnish, etc.) through the air onto a surface

Powder Coating: Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL

Frequently Asked Questions

Turning capabilities of up to 380 mm in diameter.

1. Cylindrical parts

CNC turning machines are ideal for creating round or cylindrical parts. Lathes create these parts quickly, accurately and with excellent repeatability.

2. Range of processes

Although generally used for parts of a certain shape, CNC turning can still be used to carry out a variety of cuts, including drilling, boring, threading and knurling.

3. Professional quality

To discover the more general advantages of CNC machining with Think3D, see our CNC machining services page.

While potentially any solid, stable material can be turned, we work with hard plastic and metals such as aluminum, many kinds of mild and stainless steel, titanium, magnesium, brass, copper and other alloys.

Note that some tool steel may be too hard to cut on a lathe or mill or else will require special treatment and a longer production time. Soft elastomers or plastics may also be impossible to turn since they cannot be held in a fixed position or would change in shape under the pressure of the cutting tool.

We have many additional services to provide you with a complete manufacturing solution to support your most sophisticated applications. These include CNC milling, surface grinding, laser etching, media blasting, EDM machining, hardening and more. And we can finish your parts with a world-class paint job, anodizing, chrome and nickel plating, surface passivation and printing. If you have additional requirements our team is standing by to find the solution that’s right for you.

Common tolerances for CNC turning services are .005 inches. In many cases, tolerances of +/- .0005 are possible.

Rough turning removes as much material as possible without a focus on accuracy and surface finish, getting the workpiece close to the desired shape. Finish turning “finishes” the process, producing the desired smoothness and accuracy.

CNC lathes are most often only 2 axis machines with one spindle. They also don’t have high production capabilities and typically don’t have a protective enclosure around the machine. CNC turning centers are more advanced versions of CNC lathes with up to 5 axes and more versatility in cutting ability. They also offer the ability to produce higher volumes and usually integrate milling, drilling, and other capabilities.

CNC turning is used for creating a variety of parts, including auto parts, knobs, tubes, gears, toy parts, flywheels, crankshafts, hubs & disc cams. It is most often used to manufacture parts for automotive, aerospace, medical, and other industries.

We serve the medical, aerospace, oil and gas, energy industries, and others.