PHOTOPOLYMER

- Photopolymers are compatible with a number of additive manufacturing processes. In all of these processes, a resin is cured with light, then a full part or prototype is built up layer by layer until completion.

About Photopolymer

Photopolymers have applications in a wide variety of industries, but these applications are generally highly specialized. Photopolymer resins aren’t particularly strong or durable when compared to similar high-strength injection molding materials, and they’re susceptible to creep after carrying heavy loads for a long period of time. However engineers can build small, high-resolution prototypes with even surfaces and complex geometries using this resin.

Photopolymer types avaialble

| Type | Description | Color | Process | Advantages |

|---|---|---|---|---|

| Veroclear | VeroClear is a transparent material that simulates PMMA (polymethyl methacrylate), commonly known as acrylic. Like PMMA, VeroClear is used as an alternative to glass and is ideal for concept modeling and design verification of clear parts such as eyewear, light covers and medical devices. | Translucent | Polyjet Printing | Can get transparent parts |

| Digital ABS Plus | Digital ABS Plus creates realistic, precise parts and tools that are tough and heat resistant. Designed to simulate durable production plastics, Digital ABS Plus delivers high impact strength with high-temperature resistance and superior finish. | White | Polyjet printing | High-temperature resistance with toughness |

| VisiJet CR-WT 200 | Opaque white material for parts that looks & feels like injection molded. | White | Multi Jet Printing | Extreme durability, smooth surfaces and high rigidity. Class VI capable for use in certain medical applications and delivers moderate mechanical performance. |

Quick Overview

| Processes | Lead Time | Color | Tolerance | Price | Applications |

|---|---|---|---|---|---|

| 3D Printing | 2-4 Days based on size | Available in all major colors. | 100 - 150 Microns | Lowest in market | Transparent, Smooth & Multi color parts |

Design Recommendations

| Services Name | Max Size | Min Size | Min Thickness | Features | Angles |

|---|---|---|---|---|---|

| 3D Printing | Max Part Size: 200x200x150 mm | Min Hole size : 5 mm | Min Wall Thickness: 3 mm | Min Feature Size : 3 mm | Recommended fillet & Chamfer angles : > 45 Deg |

Frequently Asked Questions

Materials required to actually ‘print’ are expensive.

Typical photopolymer materials used for SLA-based 3D printing are acrylic and epoxy resins.

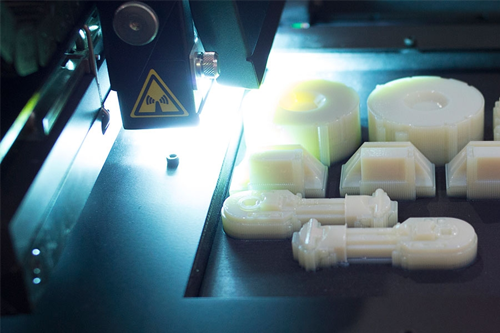

Additive manufacturing, or 3D printing, is the process of turning digital designs into three-dimensional objects.During SLS, tiny particles of plastic, ceramic or glass are fused together by heat from a high-power laser to form a solid, three-dimensional object.

3D Printers and 3D Printing: Technologies, Processes and Techniques. 3D printing is also called additive manufacturing. This term accurately describes how this technology works to create objects. “Additive” refers to the successive addition of thin layers between 16 to 180 microns or more to create an object.

There are some common denominators, for example, both use a laser to trace out and build individual layers. For SLA a liquid resin is cured, where as in SLS powder is selectively fused together.

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL