INDUSTRIES

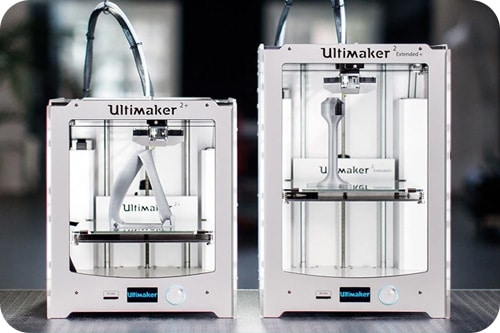

- One stop shop for all 3D Printing hardware

- Deep expertise in 3D Printing & allied industries

- Best-in-class customer service

We Represent

Medical

Medical is one industry that is getting rapidly disrupted through 3D Printing. AM is currently being used for vast variety of medical applications. Surgical guides, surgical models, medical implants, orthopedic implants, prosthetics as well are creation of patient-specific replicas of bones and blood vessels.

Automotive

For the automotive industry recent advances in Additive Manufacturing (AM) (or 3D Printing) have opened doors for newer, more robust designs; lighter, stronger, and safer products; reduced lead times; and reduced costs. In 2015, the annual Wohlers report stated that the automotive industry accounted for 16.1% of all AM expenditure.

Architecture

3D printing is set to revolutionise the way architects explore designs and innovate. 3D printing for architects empowers them easily create complex, accurate and durable scale models quickly and cost-effectively. Magnificent 3D printed architectural scale models can help architects impress their clients create and seize more opportunities. All of this can be done in-house, in a matter of clicks.

Manufacturing

manufacturing is currently the purest digital manufacturing technology available. It doesn’t require tooling or fixturing and has near-zero switching costs in moving a file from one printer to another and from one location to the next. That’s a radical departure from how manufacturing has been done over the last two centuries. Now 3D printing applications in manufacturing are transforming several industries.

Frequently Asked Questions

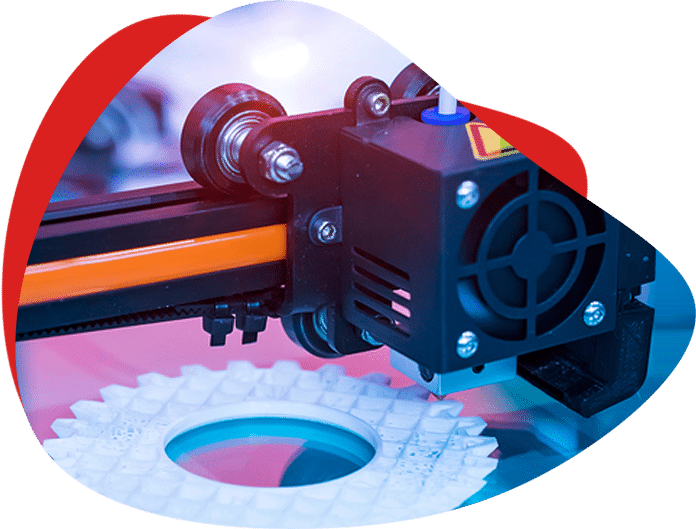

FDM stands for Fused Deposition Modeling, which simply means that material is deposited in single layers that fuse together to create a 3D object.

Stereolithography (SLA) printing was first invented in the 1980’s and works by curing resin with light. The light solidifies a liquid resin via a process called photo-polymerization and builds objects layer by layer.

Additive manufacturing, or 3D printing, is the process of turning digital designs into three-dimensional objects.During SLS, tiny particles of plastic, ceramic or glass are fused together by heat from a high-power laser to form a solid, three-dimensional object.

3D Printers and 3D Printing: Technologies, Processes and Techniques. 3D printing is also called additive manufacturing. This term accurately describes how this technology works to create objects. “Additive” refers to the successive addition of thin layers between 16 to 180 microns or more to create an object.

There are some common denominators, for example, both use a laser to trace out and build individual layers. For SLA a liquid resin is cured, where as in SLS powder is selectively fused together.

Because the sintering temperature does not have to reach the melting point of the material, sintering is often chosen as the shaping process for materials with extremely high melting points such as tungsten and molybdenum. The study of sintering in metallurgy powder-related processes is known as powder metallurgy.

To create your 3D print, a laser in the printer melts the powder together. So here’s how it works: A super-thin layer of Aluminum or Titanium powder is spread out by a roller. The print chamber of the 3D printer is then heated up.

The Powder Bed Fusion process includes the following commonly used printing techniques: Direct metal laser sintering (DMLS), Electron beam melting (EBM), Selective heat sintering (SHS), Selective laser melting (SLM) and Selective laser sintering (SLS).

MJP or MultiJet Printing is an inkjet printing process that uses piezo printhead technology to deposit either photocurable plastic resin or casting wax materials layer by layer. MJP is used to build parts, patterns and molds with fine feature detail to address a wide range of applications.

PolyJet is a powerful 3D printing technology that produces smooth, accurate parts, prototypes and tooling. With microscopic layer resolution and accuracy down to 0.1 mm, it can produce thin walls and complex geometries using the widest range of materials available with any technology.