ABSTRACT:

The accurate placement of the implant is critical for achieving the results and as well as the exact alignment. SURGICAL GUIDE plays an important role in pre-surgical planning which then becomes simpler. The computed tomography (CT) imaging and CT-derived surgical templates are clinically significant improvements in accuracy, time efficiency, and reduction in surgical error, benefiting the patient, surgeon, restorative dentist, and the laboratory. Continued advances in software applications that enable enhanced planning give clinicians the vision necessary to deliver the desired results, while serving as an excellent communication tool between all members of the implant team. This article illustrates the advantages of using CT scan-based templates through various clinical presentations. Procedures were illustrated for single and multiple tooth applications in both mandible and maxillary arches.

INTRODUCTION:

A surgical guide is a medical device that is 3D printed based on the DICOM data which is patient specific. It is used for the accurate placement of the implant in the bone structure. It replicates the exact surfaces of the patient’s intraoral situation and assists the surgeon to perform the clinical application of drilling implants into the bone with optimal accuracy. The correct angulations are builted into the guide and the exact length is known from the top of sleeve to the ape of the implant.

PROCEDURE:

SCAN:

In order to plan the treatment and design a surgical guide, the inputs collected are in two forms:

⇒DICOM data

⇒ Ceramic data.

Ceramic data is 3D scanned data generated from doctor which is patients specific with the help of cone –beam computed tomography (CBCT).

DICOM DATA

CERAMIC MOLDS

DESIGN:

Design in surgical guide make sure to select software that offers open STL file export to ensure strong and durable results.

The exact step-by step in treatment planning and surgical guide design varies by software, but generally follow:

IMPORT SCANS:

The standard file format for optical scans is .STL, the standard form of CBCT is DICOM. Most of the software allows open import, of these file. Open CBCT DICOM data software then import .STL

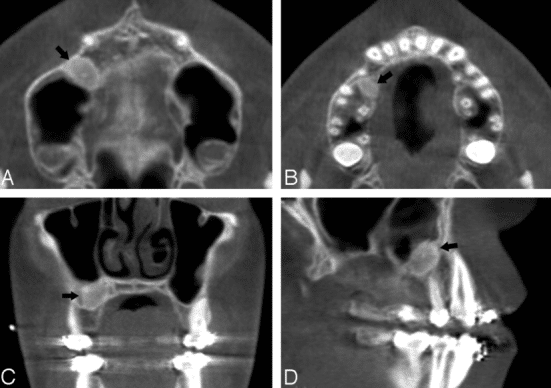

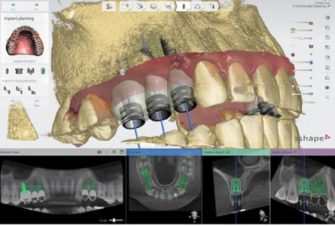

REVIEW SCANS:

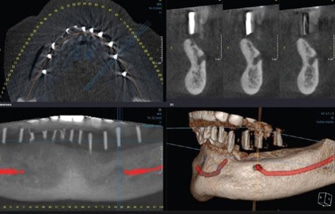

Review the CBCT scans, and identification of the mandible nerve.

ALIGN SCANS:

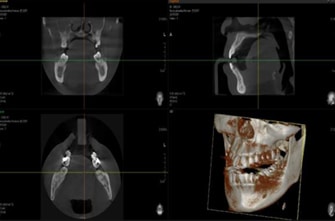

Select the implant and place it on the patient’s anatomy. Choose the position, angulations, depth and desired outcome. Surgical guide help to identify the desired area of the arch to cover. For the best retention and accuracy.

DESIGN TREATMENT:

Align the CBCT scan using both manual point of interest identification tools and automatic tools for detailed alignment. This allows both the detailed surface scan data and the CBCT bone data to be used in treatment design.

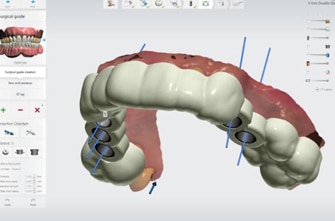

DESIGN SURGICAL GUIDE:

Surgical guides are used to improve the accuracy and safety of treatment so that implants can be placed correctly for the surgical outcome.

- Anatomy.

- Drilling holes with sleeves inserted, which comply with the treatment plan and guide the actual drills.

- Optional form features like screw holes, anchor pin holes etc screw holes, anchor pin holes.

Export:

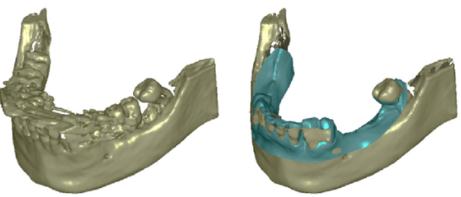

Once the design is created, export a digital model of the part in STL or OBJ file format.

PRINTING:

SLA (Stereolithography):

Stereolithography is also referred as SLA- is also one of the most popular and widespread techniques in the world of additive manufacturing. To create desired 3D shape this process converts photosensitive liquid into 3Dsolid plastics in a layer-by-layer using a low –power laser and photo polymerization.

Process includes the following steps:

- Select Material

- Import Model Files into Perform

- 3. Orient Models

- Generate Supports

- Upload the Print

- Prepare the Printer and Resin

POST PROCESSING:

BEFORE

AFTER

How this 3D does printed surgical guides help?

These 3Dprinted models help in pre-operative planning or for performing mock surgeries. It allows for pre-adaptation of surgical instruments such as fixation plates and thus shortens the operation and improves precision and allows for accurate reconstruction of anatomic relations as well as efficiently restoring function. A PSI spares the need for adaptation in the operating theater, thus resulting in highly resistant implants which can easily withstand physiological forces. The application of PSI is expanding rapidly, and we will see many more innovative treatment modalities in the near future based on this technology.

Advantages of using surgical guides in surgery:

- Accurate placement of dental implants with 3D surgical guide.

- Reducing the time of surgery because surgical plan was made on the computer before the surgery. You just have to use surgical guide and to place dental implants in appropriate position.

- To do dental implantation without additional cutting and suturing.

- Shortened rehabilitation period: without additional cutting and sutures, the pain, swelling and inflammation.

- With digital 3D modeling of surgical guide you can make surgery plan before implantation and to show the final result to the patient.

- With surgical guide you have the possibility to make dental restorations and to place them during surgical stage of dental implantation.

- You can use surgical guide as a temporary rehabilitation during prosthodontics process.

- Surgical guide for dental implantation makes the work of dental technician easier and orthopedist easier.

AUTHOR: ASHWINI VALLURI

4 replies on “SURGICAL GUIDES”

Hey, I am a medical student doing research on application of 3D printing in medicine. Could you please tell me what would be the rates of 3D printing a mandible(Lower jaw) using SLA?

Dear Mr.Rachit, thanks for contacting think3D. We are unaware of pricing, kindly drop a mail to info@think3d.in with your requirement or you can contact our technical person Ms.Lavanya on 8309413738 to know the same.

We are in to dental fabrication.. we are looking for a DMLS Machine for my dental lab in hyderabad. may i know the cost of the same

Dear Mr.Sreenivas, thanks for contacting think3D. Kindly email us at info@think3d.in regarding this so that our sales executive could get back you. For any other queries feel free to reach us on 8142896564.