SELECTIVE LASER SINTERING (SLS)

- One of the most widely used prototyping technique for functional parts and components due to its ability to create complex geometries very easily. Accurate prototypes and functional production parts with high durability, using multiple nylon based powders.

SLS & MJF 3D Printing Service

Think3D has one EOS Formiga P110 SLS machine and one HP MJF 4200 machine in-house. We have the lowest turn-around time and highly competitive price in the market for nylon based 3D Printing services.

Quick Online Quote

Upload files in Get Quote section and get quote within 4 hrs

Technical Competency

Technically qualified team in various mfg. technologies

Competitive Pricing

Highly competitive price and bulk discounts also available

NDA & IP Protection

All designs and data are kept in highly secure private server

Overview

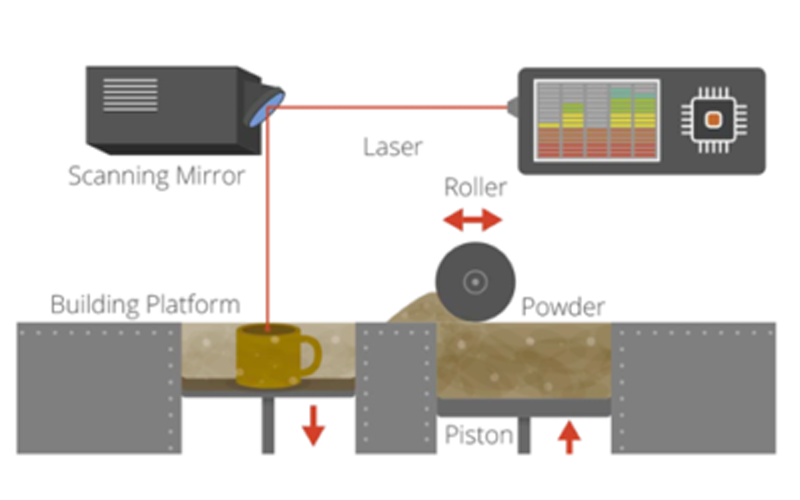

In SLS, a laser selectively sinters the particles of a polymer powder, fusing them together and building a part layer-by-layer. The materials used in SLS are thermoplastic polymers that come in a granular form.

During the 3D printing process, the SLS machine preheats the bulk powder material in the powder bed somewhat below its melting point, to make it easier for the laser to raise the temperature of the selected regions the rest of the way to the melting point. A roller will apply a layer of polymer powder, then the laser will sinter the powder according to the 3D file and the build platform will lower before applying a new layer of powder. The process will be repeated until the desired part is created.

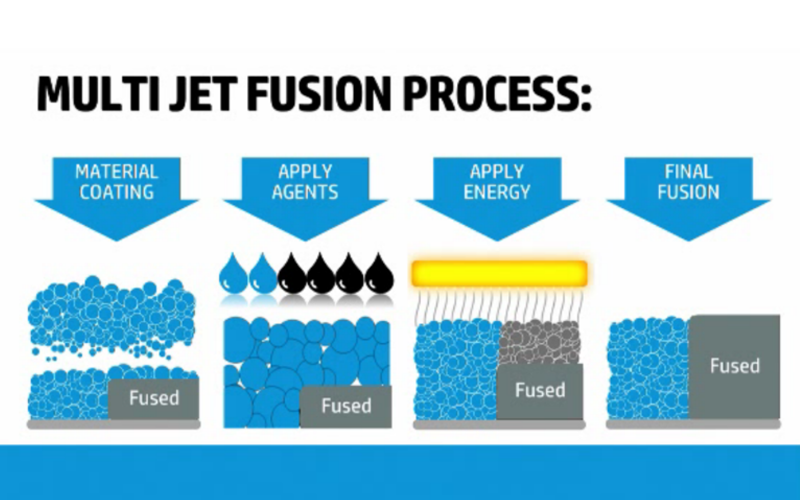

Multi Jet Fusion is a powder-based technology but does not use lasers. The powder bed is heated uniformly at the outset. A fusing agent is jetted where particles need to be selectively molten, and a detailing agent is jetted around the contours to improve part resolution. While lamps pass over the surface of the powder bed, the jetted material captures the heat and helps distribute it evenly.

The process continues layer-by-layer until a complete part is formed. After the print is finished, the build unit with the material and parts are rolled onto a processing station for cooling and powder excavation

SLS & MJF does not require support structures because unsintered powder surrounds the parts during printing. SLS printing can produce previously impossible complex geometries, such as interlocking or moving parts, parts with interior components or channels, and other highly complex designs.

These technologies also empowers designers to consolidate complex assemblies that would normally require multiple parts into a single part. This helps alleviate weak joints and cuts down on assembly time. SLS & MJF can take generative design to its full potential by enabling lightweight designs that employ complex lattice structures impossible to manufacture with traditional methods.

Applications

- Prototypes with good mechanical properties

- Small parts in limited volumes as end use parts

- Spare parts and complicated art forms

- Light weight designs

materials

Nylon PA12 White (PA2200)

| COLOR | PROPERTY | TENSILE STRENGTH (MPA) | HDT |

|---|---|---|---|

| Translucent | 930 kg/m3 | 95 | 176 |

Nylon PA12 Grey MJF

| Tensile Strength (MPa) | Density | HDT | Melting Temperature °C |

|---|---|---|---|

| 48 | 1075 | 95 | 175 |

Nylon PA12 Glass Filled (PA3200)

| Tensile Strength (MPa) | Density | HDT | Melting temperature °C |

|---|---|---|---|

| 51 | 65.02 | 176 | 175 |

Design Rules

Minimum Wall thickness:0.8 – 1 mm

Minimum details size: 2.5 mm (for text/ hole diameters etc)

Layer thickness: 0.08 mm – 0.1 mm

Max dimensions: 380 x 284 x 380 mm. Large parts can be created with assembling individual parts by interlocking designs or glueing together.

Standard Accuracy: ± 0.3% (with lower limit on ± 0.3 mm).

Lead Time: Minimum 2-3 working days for dispatch

Surface finish: Grainy matt finish

post processing

Basic: Powder removal, Bead blasting

Add on: Primer, Coating/ Painting

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL

Frequently Asked Questions

SLS/MJF is suitable for any stage of product development, from a functional prototype, to a single-use part, or to create operational pieces.

Yes we can do tapping after printing. We can also fix brass inserts if required.

Parts printed with Nylon PA12 material are biocompatible.

Parts strength wise both has similar properties.

MJF parts has slight advantage on surface finish

Yes, we can do.

Yes. But we need to give escape holes to remove unsintered powder.

120-130 Degree Centigrade

No

SLS/MJF parts are 100% dense.

SLS/MJF printed parts are 3 times costlier than FDM.

Extra cost gives more complex & quality parts.