3D DESIGNING SERVICES

- Take your ideas to the next level. Our designers take full advantage of the technological potential from 3D printing, without the constraints of conventional manufacturing methods. From concept to production, the Think3D team will help you unlock the full potential of your idea using today’s most advanced additive manufacturing design technology.

3d Designing services

Whether you are an architect, interior designer, building contractor, product manufacturer, or a designer, you require the help of a 3D designer to give life to your concepts. think3D offers various high quality 3D design, modeling, rendering services at a highly affordable price.

Quick Online Quote

Upload files in Get Quote section and get quote within 4 hrs

Technical Competency

Technically qualified team in various mfg. technologies

Competitive Pricing

Highly competitive price and bulk discounts also available

NDA & IP Protection

All designs and data are kept in highly secure private server

We have in-house

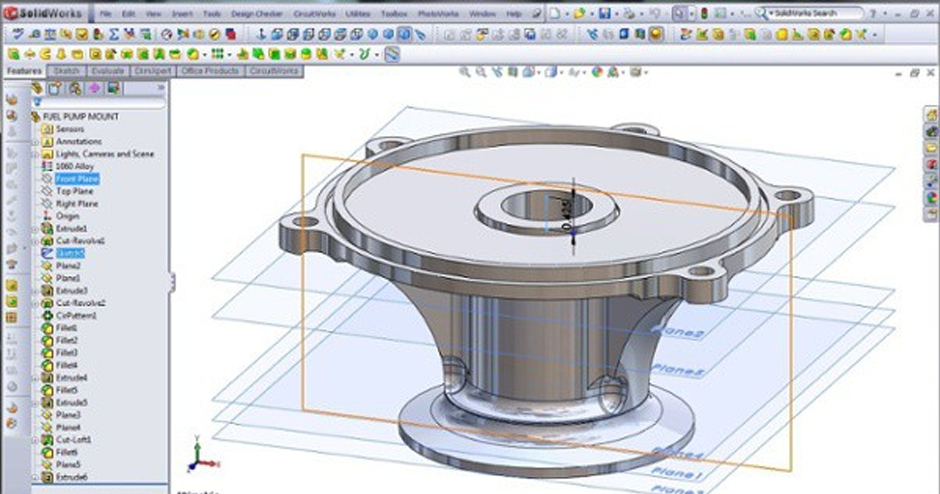

CAD Modelling

THINK3D offers CAD modeling services. While CAD is used mainly in engineering drawing and construction architecture, it can also used to accomplish preliminary design and layouts, design details and calculations, creating 3D models, creating and releasing drawings, as well as interfacing with analysis, marketing, manufacturing, and end-user personnel.

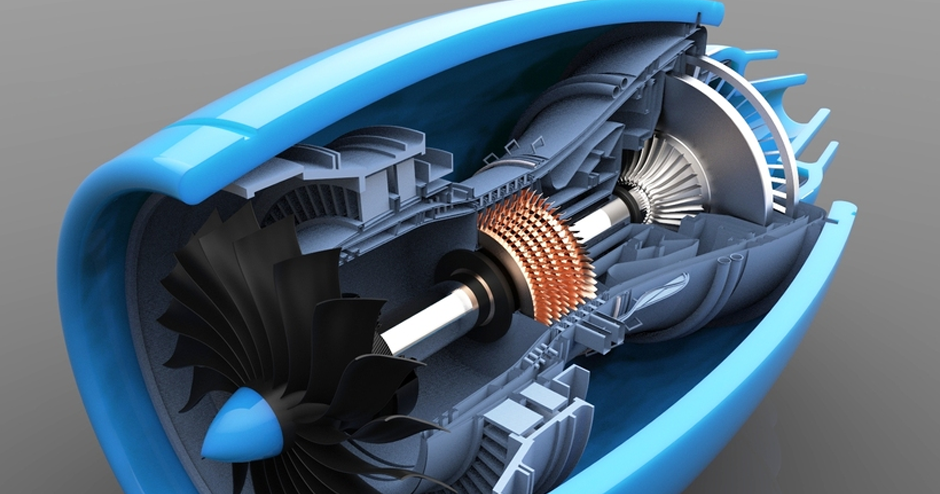

3D Rendering

With our team of experts in this field you can get the accurate 3D rendering of your design which is much better than using 2D designs. It can also avoid the short falls of the 2D designs. We are capable of making 3D CAD models from scratch or can also convert 2D designs into 3D according to our customer needs.

Miniature Design

We are specialists in creation of custom miniatures.With state of art modeling and 3D Printing services available in-house, we can offer end to end service to our customers. Our services include designing the miniature, 3D modeling and 3D Printing it. For large series, we can provide resin casting, plastic injection molding or metal casting.

Scale Models

think3D has one EOS M290 machine in-house to offer various metal additive manufacturing service. We can 3D Print various metals like Chromium Cobalt, Tool Steel, Maraging Steel, Aluminium

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL

Few Case Studies

What is Design For Manufacturing (DFM)

3D Printing of Silicon

Frequently Asked Questions

Get 3D design files in the choice of formats like STL/ IGS/ STP/Part/ Obj etc which can be used for 3D Printing/ Moulds and other applications.For rendering, we share high quality jpeg images.

We can comment on the same, only after going through the source design.

We can repair your 3D design file by correcting the mesh or by adding details or checking for non-printable areas and provide the required STL file ready for 3D printing in any of the technologies – SLS/ FDM/ SLA/ PJP/ MJP or more.

Do not worry! As a habit, we keep customer data very secure. Additionally, we sign a NDA confidentiality form, for projects requiring data security

You can upload a 3D file in any of the following formats:

.3DM, .3MF, .STEP, .IGS, .DXF, X_T, .PLY, .SLDPRT, .SLDASM, .VRML, .ZBR, MB/MA.

The inputs that you can give are rough ideas scribbled on a paper, any physical component, reference models of components, and images.

When you upload your 3D file in certain formats, for instance .obj, you should include colours, textures and the 3D model in a .zip archive. To upload your 3D model to the site, you can send the texture files like .VRML, .ZBD, .FBX files by .zipping from your computer.

When you upload a design to our gallery, you may find that some geometric issues prevent it from being built without modifications. The most common reason is that the design does not unambiguously represent a solid object. Another possibility is that some parts are too thin to be synthesized.

Many 3D software modelling tools currently available focus on creating models for rendering and animation. Most of the time, this type of software does not require the object to be solid and only represents its surface. This information is sometimes insufficient to reconstruct a solid object solely based on the 3D design.

If possible, our software tools will attempt to automatically fix the design. However, some issues require manual editing by the designer.

- One of the Benefits of CAD is to Draw to Scale.

- The ability to producing very accurate designs.

- Drawings can be created in 2D or 3D and rotated.

- Other computer programs can be linked to the design software.