A 3D printer was recently delivered to the International Space Station (ISS). Read more about it here.

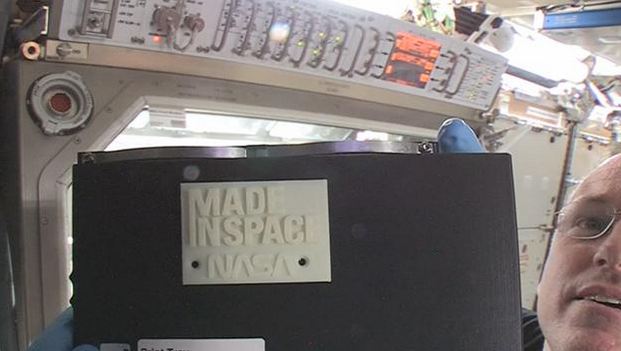

Now, a printhead faceplate has become the first object in the history to have been manufactured in the space. The 3D printed print head face plate is engraved with names of the organisations that collaborated on this space station technology demonstration, including Nasa and Made In Space.

The 3D printing device was built by California based company Made In Space. This 3D printing device will allow astronauts to test how 3D printing works in microgravity. If successful, this would make orbital output partially independent of spare parts from Earth.

As per Niki Werkheiser, project manager for International Space Station 3D printer at Nasa’s Marshall Space Flight Centre in Huntsville, Alabama, “This first print is the initial step towards providing an on-demand machine shop capability away from Earth. The space station is the only laboratory where we can fully test this technology in space”.

The commands to print an object were beamed from ISS ground control team. Mr. Niki Werkheiser mentioned “This is the first time we have ever used a 3D printer in space and we are learning from these initial operations. As we print more parts, we will be able to learn whether some of the effects we are seeing are caused by micro gravity or just part of the normal fine-tuning process for printing”.

The adhesion of the part on the print tray was stronger than expected. One possible explanation for this phenomenon is the bonding between individual layers of 3D printed obejct is different in micro gravity from what it is on Earth. More parts will be printed to figure out if the adhesion is because of 3D printing in micro gravity or just an accidental phenomenon. Werkheiser said “We chose this part to print because if we are going to have 3D printers make spare and replacement parts for critical items in space, we have to be able to make spare parts for the printers. If a printer is critical for explorers, it must be capable of replicating its own parts, so that it can keep working during longer journeys to places like Mars or an asteroid”

The first batch of made-in-space objects will be brought to Earth in 2015 for closer inspection to see how they compare with parts printed on Earth. If the printed objects prove good, then it is going to further the space exploration by reducing the need to send spare parts along with the satellite. The required spare parts can be directly printed in the 3D printer at the space station. So, no need to carry huge spare part inventory with every expedition and also it helps in proper disaster management if anything untoward happens in space.