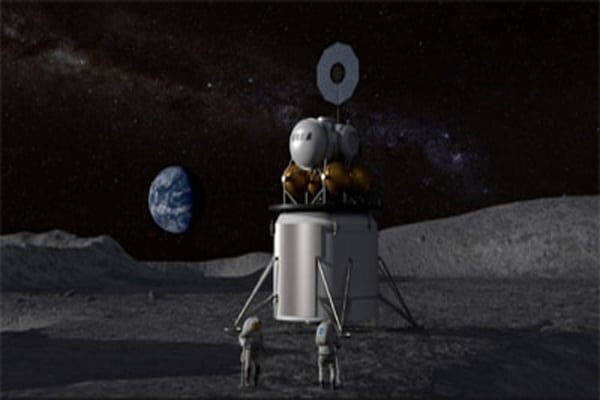

Image Source : 3d natives

3D printing applications cover various sectors. Now let us know about its advancements in the aerospace industry. Recently COSM, a leading developer and supplier of Electron Beam Wire Feed Additive manufacturing systems, announced that it will begin working on the development of 3D printing systems for a variety of future. This is funded by SBIR (Small Business Innovation Research) contract from NASA to support the Artemis program. Last September NASA selected three more small businesses for exploration of the Moon. So COSM was contacted to support its needs. The technology advanced by COSM is based on Direct Energy Deposition (DED) technology. It uses an electron beam to deposit metal from a spool of wire into a complex part. COSM also explained that it has decades of experience using charged particles beam systems in the semiconductor industry. Their new systems will monitor the whole process automatically.

“Producing large metal parts autonomously to verifiable specifications and quality in-space will be enabling part of man’s permanent presence on the moon and further mission to mars ” explained Richard Comunale, Founder and CEO. NASA will land the first woman and next man on the moon by 2024 using innovative technologies to explore more of the lunar surface. NASA aims to build sustainable elements around the moon so that it allows robots and astronauts to explore more. One of the key technology in space exploration is additive manufacturing. COSM was selected in September 2020, after NASA acquired more funds ($11.9 million) for Artemis. Its technology was selected because of its high degree of active process control, real-time inspection and flaw detection.

Producing large metal parts autonomously “is made possible by fundamental technology developed by COSM with support from NASA’s Langley Research Center. The next step in technology development will result in the core system components validated for launch and operation in transit, on the Moon and Mars,” adds Richard Comunate. COSM has been working with NASA on other projects too. “We are excited by the prospect of adding COSM’s high precision electron beam capabilities into the EBF3 process to enhance in-space welding and additive manufacturing for future exploration missions. COSM’s experience enables integrated visualization and sensing in real time to control and inspect work being performed in remote areas,” concludes Karen Taminger, Senior Materials Research Engineer and Technical lead for Metal AM Research at NASA Langley. So in this way additive manufacturing has evolved so much in the aerospace industry.