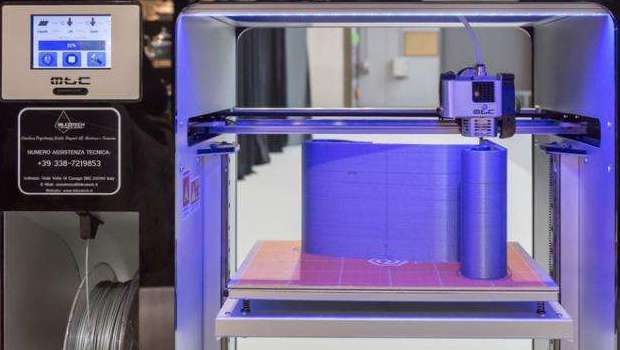

Additive manufacturing is a $4 billion venture that is all set to expand 4 times by 2020. In a few years, everything from clothes, shoes, medicines to cars will be 3D printed. The Federal Aviation Administration certified its first 3D printed component for GM jet engines and the Ford motors id using AM to create parts and accessories.

But just like the electronics sector, this segment also faces problems of untrustworthy parties that are a part of the global supply chain. This was reported by a group of cybersecurity and materials Engineers at NYU Tandon School of Engineering in JOM, Journal of Minerals, Metals and Materials Society.

The two areas that have been identified as susceptible to security issues is printing orientation and insertion of fine defects. These foci for attacks could result in weakening of the end product and lawsuits and recall. This was stated by Nikhil Gupta the associate professor at the NYU Tandon School of Engineering.

In the process of designing the CAD files are designed and sent by the designer to the manufacturer, the files are then deconstructed into slices by manufacturing software and read into the printer head. The printer then commences the printing. The orientation of the product in the printing process enhances the strength by 25%. But if the CAD files do not give orientation instructions the processes could get altered without being identified. The best printer would be the one that reduces the use of material and increases the production capacity.

The team comprised Gupta, Steven Eric Zeltmann, Ramesh Karri, Michail Maniatakos, Nektarios Tsoutsos and Jeyavijayan Rajendran. Karri, a researcher, stated that with cloud technology and decentralized environment, the additive manufacturing technology stands a big chance of potential harm on the reliability of its products.

They said that the hacker could hack into the system when the product was being 3D printed and create defects which could pass undetected by the common monitoring techniques. This would lead to weak product or eventually failure in the performance of the 3D printed materials.

Source: phys.org