Though the market for consumer level 3D printers is relatively new but among the ones that are present in the market have either of the two technologies Fused Deposition Modeling (FDM) or the Stereolithography (SLA). Among these two techniques the SLA technique is the oldest method used for creating 3D printed objects. In this method the liquid plastic is hardened with the help of Ultraviolet (UV) ray layer by layer and this process converts liquid plastic to solid objects.

Orange Maker, a 3D printing start up based in Los Angeles is aiming to bring about a revolution in the 3D printing arena with the help of a new technique called Heliolithography method (HL). With each passing day there is always something new in the 3D printing industry but this technique is as abridged version of the SLA technique. This new technique uses UV light which is directed with high precision to polymerize liquid resin into solid plastic. In contract to SLA, the HL method is a continuous printing process which in other words mean saving time. The other benefit is that the finished product has a high level of detailing with was not possible with the SLA method. Doug Farber, co-founder of Orange Maker said, “The HL innovation provides a solution for photopolymer based 3D printing that solves the adhesion issues that are common in SLA systems. In addition, HL technology represents a major breakthrough in process scalability, allowing the printing process to be carried out from the micro-scale through theoretical size limits greater than current large-scale industrial printers.”

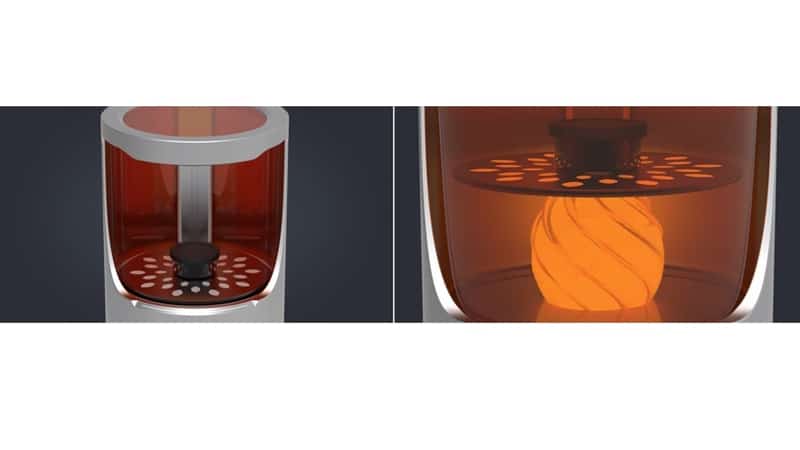

This new technique of HL has been applied to the Helios One a new 3D printer designed by Orange Maker. The company at present has proto-types ready for manufacturing and field testing. The Helios One is different from FDM and SLA type of desktop printers on the following grounds:

- Continuous and efficient build process

- Large scalable build area

- Ultra-high resolution

- Reliable printing process with fewer failed prints

Co-founder of Orange Maker Kurt Dudley said, “Quite simply, we’ve found a way to streamline efficiency, design, and material economy in 3D printing, a medium that has hitherto suffered from restrictions on variables such as size, speed, and availability of materials,” “We’ve reached an ideal—greatly expanding functionality while achieving elegance and simplification through design and engineering.”

Orange Maker is currently all set to manufacture a second generation of proto-types to field test the product. Moreover the company is interested in research and development stage for formulating optimized printing materials for usage in the Helios One 3D printer. The company is also interested in developing tools including desktop applications and mobile apps that are specifically designed for the HL 3D printing systems. The Helios One will be released in the market most probably by 2015 and people can purchase the machine directly through Orange Maker or from some third party. The printer models are yet to be known. The guessing game is one about the price and the kind of work that can be done by this printer.

Image Credit: http://www.orangemaker.com