Medical Designing & 3D Printing Service

Specialists in manufacturing patient specific implants

THINK3D MEDICAL is the medical division of THINK3D, one of India’s largest integrated digital manufacturing service provider based out of AP MedTech Zone, Vizag. THINK3D MEDICAL is borne out of our deep understanding of 3D Printing space and how it can help reduce some of the major pain points in medical industry. We offer an end-to-end solution for surgical planning, guides creation, patient specific implants manufacturing. With a state-of-art manufacturing unit, deep expertise in medical and strong advisory panel, we can be your most reliable partner in deploying 3D Printing technology in medical space.

ISO Certification

Upload files in Get Quote section and get quote within 4 hrs

One Stop Shop

Technically qualified team in various mfg. technologies

Technical Consultancy

Highly competitive price and bulk discounts also available

NDA & IP Protection

All designs and data are kept in highly secure private server

Soft Tissue & Bone Modeling

Cutting & Drilling Guides

Custom Implant Design & Manufacturing

Educational Models 3D Printing

Orthopaedics

Spine Surgery

Oral & Maxillofacial

Neurosurgery

Cardiology

Input for mfg. guides, models, implants is CT, MRI scan. The scans can be uploaded using below form or sent via courier or our rep shall come and collect it.

Post data acquisition, our design team and specialists shall sit with doctor and using state-of-art modeling software, will prepare the required design.

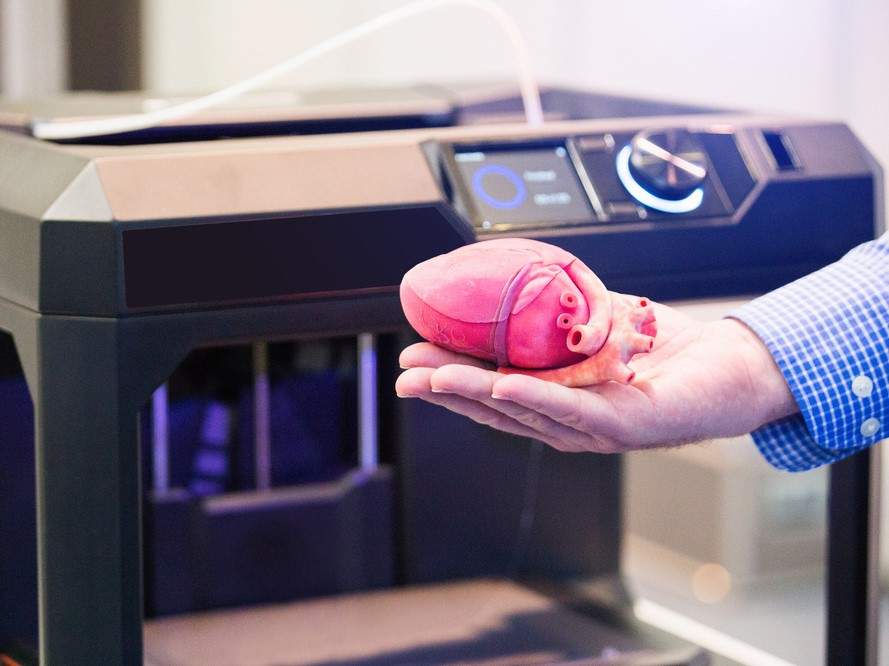

Once design is finalized, it is converted to STL format and handed over to the mfg. team to 3D Print the model using material grade material.

The 3D Printed model / guide / metal implant along with accessories are then handed over to the doctor for operational procedures.

Turn your ideas to reality with our full fledged 3D Printing, CNC Machining, Casting & Molding service capabilities. Our facility is equipped with entire range of 3D Printing technologies, 10 CNC Machines, 2 Injection Molding Machines and have a passionate team to serve you.

Turn your ideas to reality with our full fledged 3D Printing, CNC Machining, Casting & Molding service capabilities. Our facility is equipped with entire range of 3D Printing technologies, 10 CNC Machines, 2 Injection Molding Machines and have a passionate team to serve you.

Turn your ideas to reality with our full fledged 3D Printing, CNC Machining, Casting & Molding service capabilities. Our facility is equipped with entire range of 3D Printing technologies, 10 CNC Machines, 2 Injection Molding Machines and have a passionate team to serve you.

Turn your ideas to reality with our full fledged 3D Printing, CNC Machining, Casting & Molding service capabilities. Our facility is equipped with entire range of 3D Printing technologies, 10 CNC Machines, 2 Injection Molding Machines and have a passionate team to serve you.

- Dr. Mahender Reddy

Turn your ideas to reality with our full fledged 3D Printing, CNC Machining, Casting & Molding service capabilities. Our facility is equipped with entire range of 3D Printing technologies, 10 CNC Machines, 2 Injection Molding Machines and have a passionate team to serve you.

Turn your ideas to reality with our full fledged 3D Printing, CNC Machining, Casting & Molding service capabilities. Our facility is equipped with entire range of 3D Printing technologies, 10 CNC Machines, 2 Injection Molding Machines and have a passionate team to serve you.

Latest News