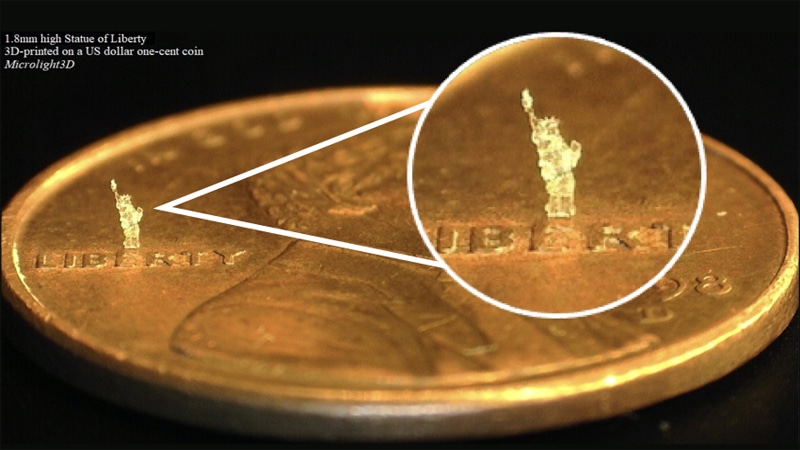

Image Source: 3d natives

One of the manufacturers of high resolution 3d printing is Microlight3D. They have 3D printed the smallest replica of the statue of liberty and showed their Long-Range Z feature. Last month they showcased the similar project, having 3D printed the smallest champagne pyramid using its microfabrication 3D printing technology. The pyramid was just 2 millimeters high. Now they came up with the new Z feature measuring 1.8mm high by 0.6mm wide. Using this feature enables users to create tiny structures up to 10mm tall. The material used in the statue is OrmoGreen. OrmoGreen is a polymer doped with silica nanoparticles which has the properties similar to that of glass.

Philippe Paliard, co-founder of Microlight3D said that ” Users will also be able to make alignments on a pre-existing pattern and print exactly where they want”. He continues, “researchers and industrial developers are looking to work on metallic or silicon wafers. Our enhanced 3D microprinting system, compatible with a wide range of materials and substrates, will allow them to micro-fabricate structures they couldn’t before; they will marvel at the ability of our µFAB3D – Advanced 3D-microprinter to align the laser and print on the tip of optical fibers for micro-optics applications.”

The world’s smallest replica may seem like a light-hearted achievement, as Paliard notes connotations are significant. This is true for those who are using microfabrication for medical devices, micro-parts and other applications. With the help of this micrometric resolution it is possible to make even the smallest designs. The Long-Range Z feature helps to fabricate mechanical materials and medical devices such as stents and micro-needles for transdermal injection. It is also used in lenses and many more.

With the advancement of new features and technologies everything is possible. So with the help of 3D printing technology Microlight3D is creating wonders one after the other.