3D printing has substantial advantages like speed, efficiency, customization, strength, durability, and affordability. Makers are constantly looking for newer designs and better technology that aids them in developing high-class 3D printing objects. But due to high costs and challenges faced in operating the equipment, makers are unable to reach the level of efficiency and outcome which they aim at.

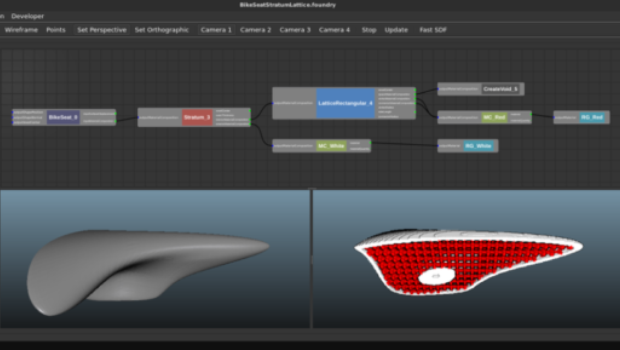

The ‘very busy’ team of MIT’s Computer Science and Artificial Intelligence Lab(CSAIL) stated that the production was complex and difficult in the case of multiple-material and multi-color 3D printing. Though processes are available, designing the products is a complex task. Foundry is a tool developed by them for creating objects in multiple materials.

The foundry tool works as-

• Design your object and export it

• Create a graph based on 100 fine-tuned actions.

• Subdividing objects in different materials

• Remapping the co-ordinates

• Giving different properties to various parts of a system

The foundry tools have preview setting to show the user the current settings of the printer. The operations can be linked in a chain as the user mixes the different combination of settings. The System can be tuned for finer printer with multiple materials at fine resolution.

In traditional manufacturing, and even the existing 3D printing processes, Different parts using multiple materials are printed separately and then assembled using adhesives. But now with systems like foundry, it would be possible to design products of new materials of optimal thermal, mechanical and conductive properties.

The team doing research on the foundry tool is headed by Vidimče. They have stated their findings in ‘Foundry: Hierarchical Material Design for Multi-Material Fabrication,’ which is authored by MIT professor Wojciech Matusik and his students of the Computational Fabrication Group: Ph.D. student Alexandre Kaspar and former student Ye Wang.

Source: 3dprint.com