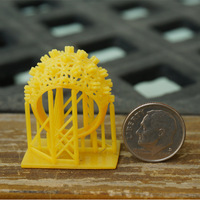

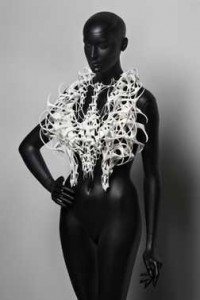

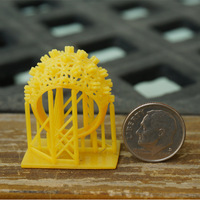

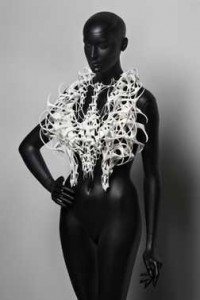

| Sample Image |  |  |  |  |  |  |  |

| Process | Material heated to a semi-liquid state, and 3D model built up one strand at a time | UV Laser beam hits a thin layer of photopolymer resin design, and solidifies it by curing | Conventional light source like an arc lamp is applied to the entire surface of photopolymer resin in a single pass for curing | Powder layers spread on top of each other, and selectively sintered by a CO2 laser beam as per the CAD data | Layer by layer by depositing a liquid binder onto thin uniform layers of powder via roller mechanism and a feed piston | Build materials selectively jetted through multiple ink jet heads | Silicone moulds created by casting material around the master model is used to create copies |

| Subject | thermo plastics | Photo polymer resin | Photo polymer resin | Powder | Powder | Photopolymer liquids | Silocine |

| Medium | Heat | UV Laser | DLP Light Source | CO2 Laser Beam | Liquid Binder | UV Light | Vaccum chamber |

| Material Options | PLA, ABS, Nylon, Wood, HIPS, PMMA | Clear/ Castable/ Tough/ Flexible Resins | Castable/ Pigmented Resins | Nylon, Aluminium, Steel | Sandstone | | Rubber, Plastics like ABS/ PP |

| Typical Layer Resolution | 100 Microns | 30 Microns | 40 Microns | 25 Microns | 50 Microns | 50 Microns | NA |

| Output Characteristics | Good Strength, lesser accuracy and needs post processing for good surface finish | Excellent Surface Finish

High Accuracy

Lesser Strength over time | Excellent Surface Finish

Good Accuracy

Lesser Strength over time

Faster turnaround | High Strength

Good Accuracy

Slightly rough Surface

High Complex shapes possibility | Textured surface

Full colour Output

Low Strength

| Smooth Finish

Multi Material Options

High Accuracy | Good Accuracy

Good Surface finish

Good Strength |

| Cost | Very cheap | Very high cost | High cost | Costlier than FDM

Very high Cost for Metals | High Cost | High cost | Economical |

| Typical Applications | -Mechanical Parts

-Architectural Prototypes

-Quick Proof of Concept | -High Precision parts for display

-Castable parts for Jewelry & Dental | -High Precision parts for display

-Castable parts for Jewelry & Dental | -Mechanical Prototypes

-Complex parts & Accessories | -Architectural Models

-Full Color Miniatures

-Display Parts | -Multi material parts for functional prototypes with exact characteristics | -Low volume production run

-High finesse requirements |

2 replies on “Rapid Prototyping Techniques – Comparison”

n nmhtiotfyti

page not scaled properly