When it’s about the most productive and quality 3D printer brands, Ultimaker is hard to miss. Ultimaker is a Dutch brand that has managed to make huge name and fame for itself with its invincible 3D printer range.

There is no denying the fact that 3D market has many other competitive brands available out there like Makerbot, Zortax, BCN3D, etc. but, Ultimaker has established a name that is beyond any competition. Ultimaker has recently launched the next version 3D printer series name Ultimaker 3 & Ultimaker 3 Extended.

Ultimaker 3 was in news since the launch of Ultimaker 2 back in 2013. Ultimaker 2 is modeled for dual extrusion but in the end only single extrusion version is launched. Dual extrusion is implemented in Ultimaker 3. Ultimaker 3 has a build volume of 215 x 215 x 200 mm. It offers a maximum resolution of 20 microns and can support various kind of files including STL, OBJ & newly launched 3MF formats.

Ultimaker 3 Technical Specifications:

| Shipment Weight | 15.5 Kgs |

|---|---|

| Technology | FDM |

| Layer Resolution | 20 Microns |

| Product Weight | 10.6 Kgs |

| Product Dimensions | 342 x 505 x 588 mm |

| Power Requirements | 100-240V ,1.4 AMPS |

| Storage Temperature | 0-32°C |

| Operating Temperature | 15-32°C |

| Extruders | Dual |

| Build Volume | 215 x 215 x 200 mm |

| Supported Filament | PLA, PVA, ABS, CPE, Nylon |

| Nozzle Diameter | 0.4 mm |

| Filament Diameter | 2.85 mm |

| Print Speed | 30 – 300 mm/s |

| Travel Speed | Up to 300 mm/s |

| Connectivity | Wifi, ethernet, stand alone via USB-drive |

Ultimaker 3 Extended Technical Specifications

| Shipment Weight | 16.8 Kgs |

|---|---|

| Technology | FDM |

| Layer Resolution | 20 Microns |

| Product Weight | 11.3 Kgs |

| Product Dimensions | 342 x 505 x 688 mm |

| Power Requirements | 100-240V ,1.4 AMPS |

| Storage Temperature | 0-32°C |

| Operating Temperature | 15-32°C |

| Extruders | Dual |

| Build Volume | 215 x 215 x 300 mm |

| Supported Filament | PLA, PVA, ABS, CPE, Nylon |

| Nozzle Diameter | 0.4 mm |

| Filament Diameter | 2.85 mm |

| Print Speed | 30 – 300 mm/s |

| Travel Speed | Up to 300 mm/s |

| Connectivity | Wifi, ethernet, stand alone via USB-drive |

Product Features

Here is what you can expect in Ultimaker 3 series 3D printers.

Dual Extrusion:

Earlier in 2013 when Ultimaker 2 was released, many expected it to have dual extrusion capability. However, it wasn’t implemented in Ultimaker 2 series 3D printers. The Ultimaker 3 offers a new dual extrusion system. With Ultimaker 3 series 3D printers, it is very easy to create print products using dual materials.

Because of dual extrusion capability, more intricate parts can be printed using Ultimaker 3 series 3D printers. You will be able to use full range of engineering materials such as two color, dissolvable PLA and Nylon materials. The extrusion system is crafted on one of the print heads and it is easy to reach out to it. The nozzles are easily detachable, so you can easily replace the older nozzle with the newer one as per your need. As it is open ended, you can also add custom nozzles to suit various new materials.

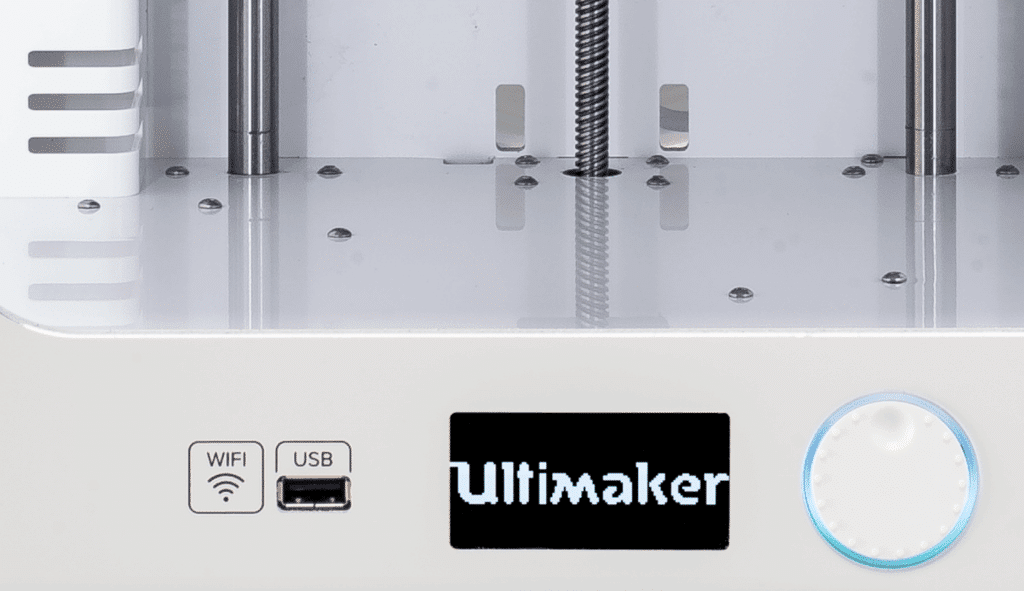

More Connectivity Options:

For the longest time, Ultimaker provided only SD card option for transferring GCode files to the 3D printer. With Ultimaker 3, wifi and USB option are provided for the same purpose. This printer can be connected to Cura software with the help of wifi or LAN network. On the downside, this machine does not come with proper touch screen. It could be disappointing for some people because the machines that cost way less than this one come with amazing touch controls. However, the controls are exceptionally simple to operate and are very spontaneous.

Professional Material:

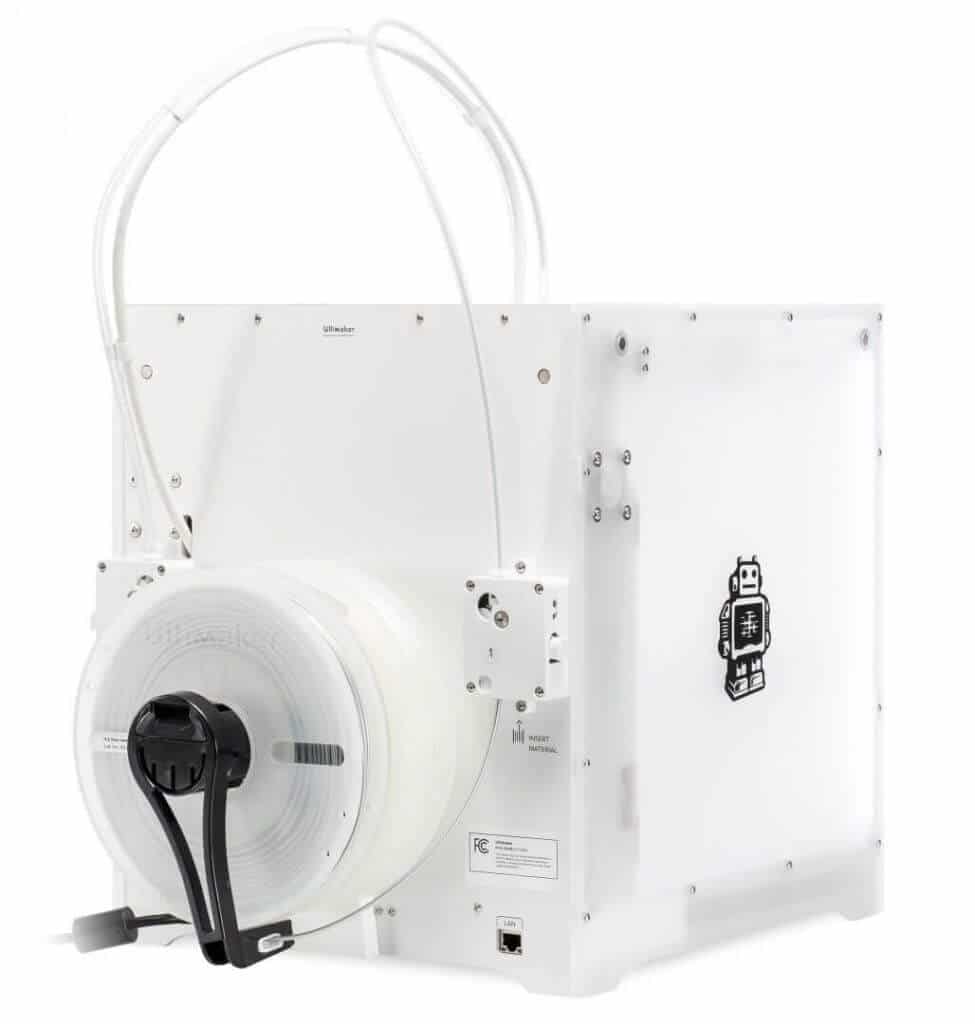

Ultimaker 3 comes up with a “Smart Material Detection” feature. It requires a special material spool that contains NFC chip and the filament holder can read the properties of the filament and configure the 3D printer accordingly. These properties can be overridden in the Cura software. This means other open ended filaments can also be used with the 3D Printer.

In Built Camera:

What we like the most in this printer is its high-end inbuilt camera. This camera assists in remote monitoring of the print output and it is connected to the open source Cura software. With the help of this feature, big organizations can increase the productivity of their work and it will also boost efficient workflow. Other than that, you can free yourself from the frequent trip to the printer and constant monitoring it if the print is still sticking to the bed.

Conclusion

As with every new launch, Ultimaker doesn’t stuff the 3D printers with lots of features but just focus on improving the quality and reliability of the machine. In many other brand machines, there are lots of features but most of the times these features don’t work. Ultimaker makes sure the features it adds to its machines just work. Ultimaker series has increased its bar in providing better features to the users. The machine is very easy to operate, tweak and set up. The print quality is amazing and due to its 3rd party material compatibility, this machine has become most liked model among the competitors. After exploring all its amazing features we would say that this printer is crafted to deliver.

Click on the below links if you wish to purchase this 3D printer in India –

https://www.think3d.in/product/ultimaker-3-extended/