Introduction

3D Printing & 3D Scanning helps in reverse engineering of various products. This enables growth and provides a clear competitive advantage to companies incorporating reverse engineering technology.

Here is a case study on how 3D Printing & 3D Scanning help cooking & cutlery industry. It is very common to see the cookware handle breaking down. In many such cases we have to replace the entire cookware as the spare handle isn’t available. This is more so common when the product reaches the end of its life cycle. With the help of reverse engineering we can actually create a replica of the handle. Below case study illustrates the same.

Case Study

This case study illustrates the advantage of 3D Scanning and 3D Printing over conventional processes in Crockery and Cutlery industry. Here , by taking an existing cooker-handle as reference , we create a new cooker-handle with a few design modifications.

(a) Original Product:

Below is the original product that we are going to scan and reverse engineer.

(b) Pre-processing:

In this stage, the component is made ready for 3D Scanning by painting the cooker-handle with a removable spray. This process helps avoid light reflections and enhances accuracy.

Time taken for pre-processing: 45 minutes

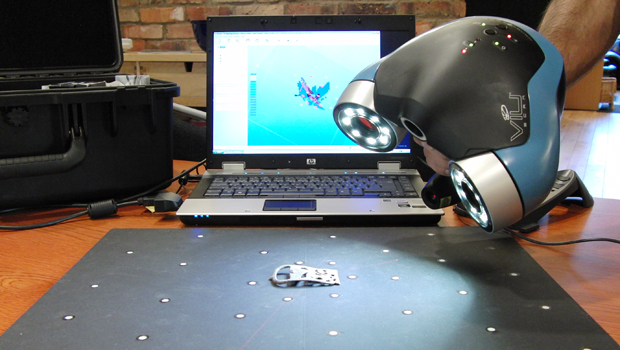

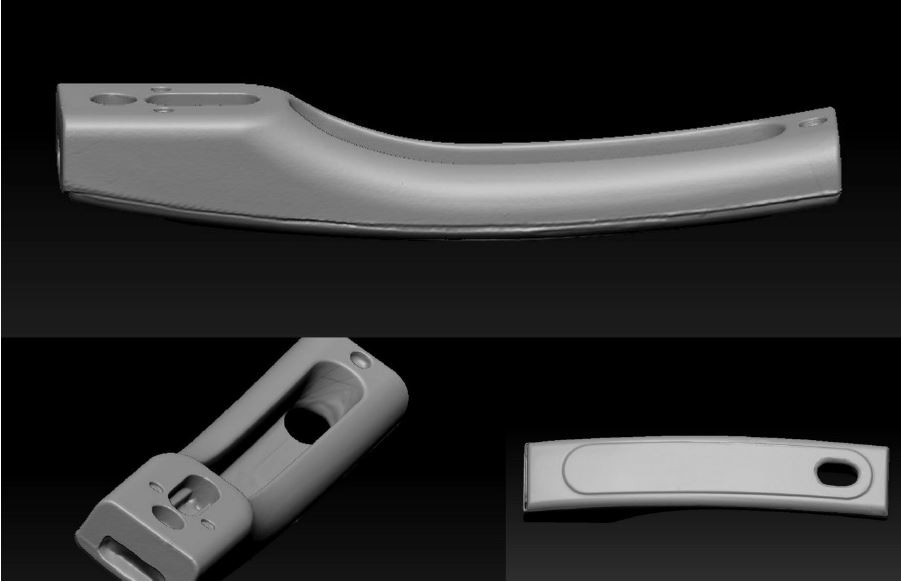

(c) 3D Scanning:

Here, the handle is scanned using a 3D Scanner. The 3D model of the handle obtained from scanning is used for further modifications.

Time taken for 3D Scanning: 30 minutes

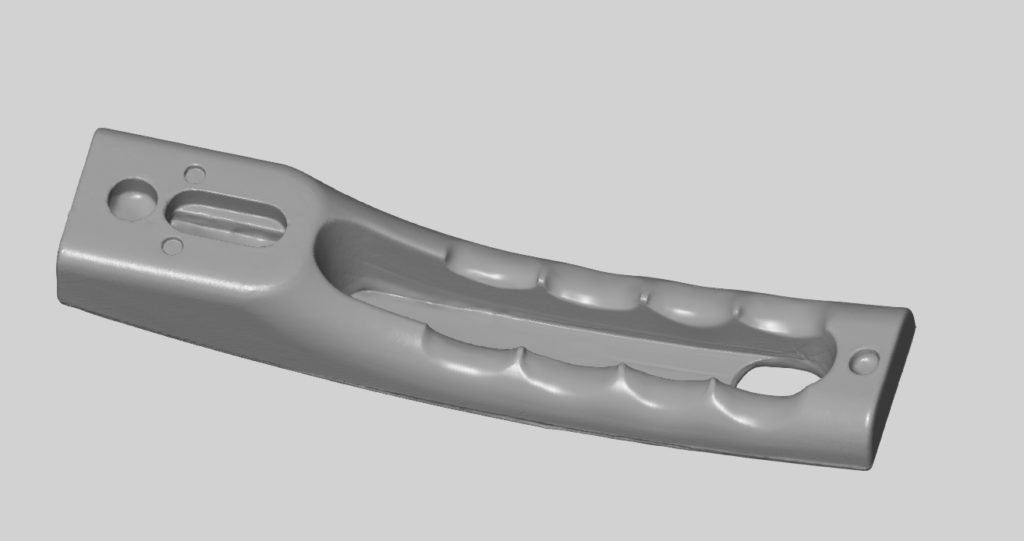

(d) Re-Designing

Here, the 3D model from the scanning is exported into appropriate designing software to modify the scan to add pattern for better grip.

Time taken for re-designing: 90 minutes

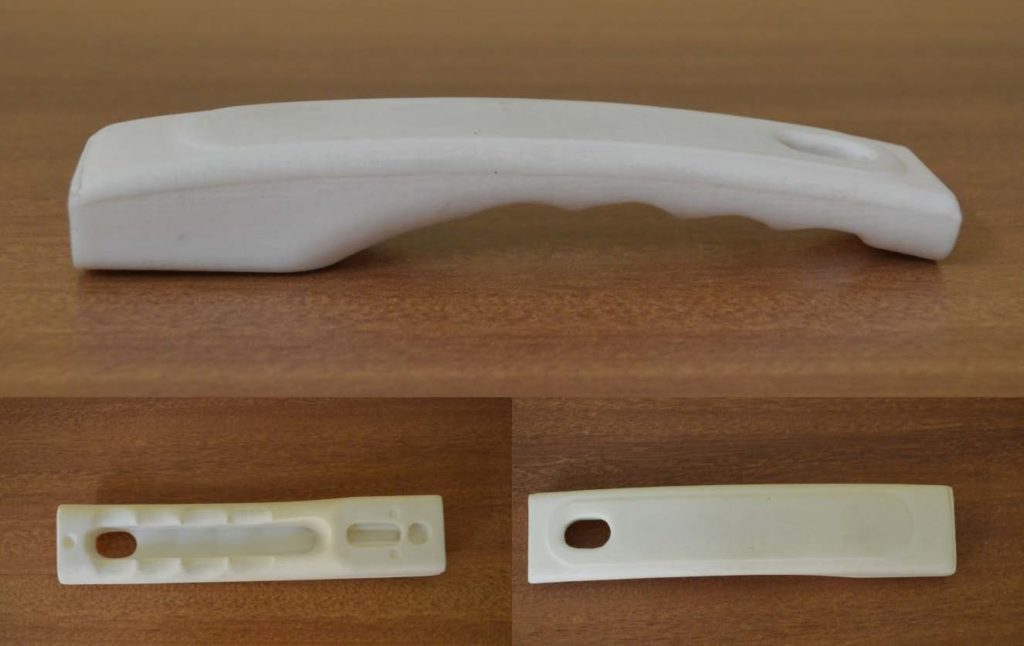

(e) Prototyping

The re-designed cooker-handle is printed using 3D Printers.

Time taken for 3D Printing: 180 minutes

The entire exercise took less than 6 hours from inception to prototype of a new design.

Adopting these technologies into your process gives you flexibility at a fraction of cost to experiment with new designs as the turnaround time is reduced from weeks to hours.

How think3D can help you adopt these technologies in your company?

Think3d – India’s largest 3D printing platform – partners with you and aids in enabling you to use these technologies to your advantage. In addition to providing sales and services of 3D printers and scanners that suit your need and budget, we also provide 3D Designing, 3D Scanning and 3D printing services. Our highly qualified team will train you in using this equipment ‘in – house’ and our dedicated support team makes sure that your equipment is always up and running.