It has been believed by Mihai Chiriac, from DS 10 Studio at Westminster University that the concept of Aquaponic housing will be able to create mini-ecosystems in well established living areas. These can also sustain the growth of vegetables and fish.

This momentous idea achieved the spotlight of the Inhabitat’s Biodesign Competition, in the end accepting a decent say as a finalist – with green growth ideas bringing home the gold towards the beginning of October. Be that as it may, Chiriac’s idea is particularly engaging as it imagines home development utilizing straightforward reused plastics and making a totally independent living environment.

Key to that arrangement is a shut circle aquaponics framework, “an advantageous interaction amongst hydroponics and aquaculture.” The three-level 3D printed home basically houses a hydroponic domain, in which plants can be developed without soil in a develop bed situated over a water tank. In that tank, you can discover the aquaculture or the cultivating of consumable fish and other amphibian life frames. The waste from the fish tank (counting uneaten nourishment produced using the plants) is changed into the key smelling salts rich supplements that the plants require, making a shut circle of sustenance development. Truth be told, it could yield more sustenance per square foot than whatever other types of farming.

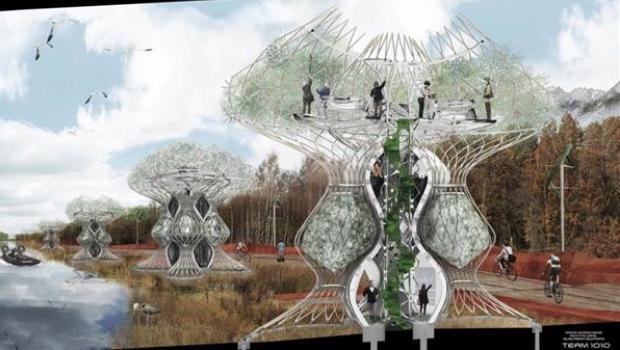

In the meantime, the plants make a sound, green living environment for the real inhabitants, and give an approach to get away from the disregarded urban spaces of today’s reality. Be that as it may, as Chiriac clarifies, the choice to settle on 3D printed bioplastics is additionally a legitimate one. “The building utilizes novel structures and creation, proposing lightweight twist dynamic aquaponic towers, which support developing harvests and angling,” he says. “The towers encase inhabitation units which are 3D printed utilizing bioplastic made as a part of the house from vegetable starch. This adaptable place without bounds goes about as a Rep-Rap 3D printer utilizing mechanical manufacture for both weaving carbon upgraded bioplastic poles and additionally expelling bioplastic layers.”

It’s a captivating idea that puts a totally extraordinary turn on the solid based development 3D printing arrangements we have seen as such. For while more financially savvy than existing development approaches, those solid based projects do nothing to recover urban brownfield destinations or make more effective utilization of constrained accessible spaces – which will go under expanding weight to the house a quickly developing populace.