In the last 2-3 years, 3D printing technology has suddenly caught the fancy of any one remotely following the technology industry due to the advent of consumer level printers. But, this wonderful technology has indeed been available to the manufacturing business for the past 2 decades. Most people relate 3D printing to FDM technology, wherein the plastic material gets extruded from the nozzle and deposited layer by layer on the build plate creating a 3D dimensional object. But truth is, FDM technology evolved later and SLA is the first technology that was invented. Charles Hull invented SLA technology and went on to build 3D Systems. Overtime, many new technologies emerged into the market. In total, there are 7 well accepted technologies. These technologies together is called 3D Printing. In simple terms, 3D printing can be defined as a process that can turn print 3D models into physical objects, in different raw materials using various additive manufacturing technologies. In this article, we shall look into various 3D printing technologies that are popular in the market now:

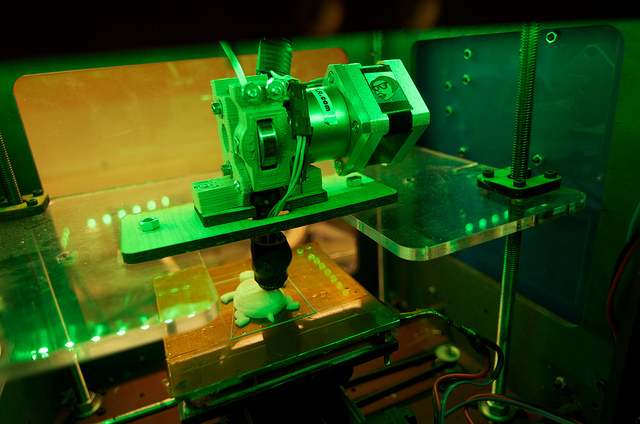

Fused Deposition Modeling (FDM)

FDM is considered to be the most common printing method. The FDM printers use thermoplastic filament which is heated till the plastic melts and then the molten plastic is placed layer by layer to form the model. This is the most widely used technique for 3D printing because it affordable, easy to maintain, uses real engineering grade thermoplastic. The bonding force of FDM type printers isn’t very strong. This leads to layer separation of resulting prints compromising on the resolution and surface smoothness. Also, if the diameter of extruded plastic line gets smaller, the printing speed will come down drastically. FDM is popular with companies from wide range of industries – from automotive to consumer goods manufacturing. These companies mainly use this technology to built proto-types. FDM was developed by Scott Crump in the 1980’s. He was the CEO founder chairman of Stratasys Limited. Stratasys Limited is currently the leading producer of 3D printers during this decade. Most desktop level 3D printers in the market currently are FDM based 3D printers.

The video below illustrates FDM technology in detail. If you wish to watch many such videos, check out youtube channel at https://www.youtube.com/user/think3dindia

Read: Comparison of various FDM printers

Stereolithography (SLA)

The Stereolithography or the SLA is a rapid proto-typing process which makes 3D models from photo-sensitive resins or photo polymers. It uses a UV/ laser that are controlled by the computer to make a 3D model layer by layer. The best feature of SLA technology is that it is fast and accurate. The quality of finish is much better than FDM technology. Also, the finished object has better mechanical strength than FDM technology prints. The only disadvantage of SLA technology is the price. SLA printers are very expensive in the market. Benefits of SLA technology are:

• The pieces are crisp and highly detailed

• The speed of production is very high

These two factors make Stereolithography the cutting edge technology that can be applied to any industry including oil refining, petrochemical, power, marine, and municipal and medical. This technology is widely used in the jewelry business. Unlike the FDM process, in this process after the production the model needs to undergo post-curing process to impart strength to the model. This process was patented as a rapid proto-typing method in the 1980s’ by Charles Hull, who was the co founder of 3D systems, inc., a leader in the 3D printing industry.

The below video illustrates SLA technology.

Read: Review of Form1 SLA printer

Digital Light Processing (DLP)

Digital Light Processing (DLP) is very similar to SLA technology except that in DLP uses projector (like the kind used for office presentations or in home theaters) to cure photo polymers. It projects the image of the cross section of an object into a VAT of photopolymer. The light selectively hardens only the area specified in that image. The most recently printed layer is then repositioned to leave room for unhardened photopolymer to fill the newly created space between the print and the projector. Repeating this process builds up the object one layer at a time. DLP is known for its high resolution, typically able to reach a layer thicknesses of under 30 microns, a fraction of a sheet of copy paper.

The below video illustrates DLP technology.

Selective Laser Sintering (SLS)

This process is one of the most affordable means of making proto-types, contributing to the wide usage of this technology among the inventors, hobbyists and in different types of businesses. But on the negative side, these machines cannot be used in offices as they need special environment. Like SLA, this machine also uses high powered lasers which are potentially dangerous for office or private usage. This process is extremely beneficial for industries that require production of proto-types in a small quantity having high quality. For example: the aerospace industry for building proto-types plane parts.

This is a similar process to Stereolithography, but in SLS a computer controlled laser beam is pulsed down on a platform, that traces the cross section of objects into small particles of plastic, ceramic or glass. The laser heats the powder either below its boiling point or above the melting point so that the powder fuses together to form a solid structure. This process continues till the entire model is finished. This makes it a largely accepted process for creating proto-types as well as final products.

The process was developed and patented by Cral Deckard, an undergraduate student at university of texas and his mechanical engineer professor, Joe Beaman in the 1980s.

Below video shows SLS technology in detail

Polyjet/ Inkjet 3D printing (PJP)

Poly jet process is very similar to the ink jet printing done on paper but in this process, instead of jetting drops of ink onto paper, the printer jets layers of liquid polymer onto a tray and then the UV rays instantly cure the model. This results in the creation of a perfect proto-type. The models that are created by these printers do not require any curing time. The models can be used after the printing is done with. While printing the model the printer jets out a gel like liquid that provides strength to the model and upholds any complex geometric design on the model.

The benefits of these printers are fine detail, smooth surfaces along with speed and precision. This machine can work on a vast array of materials right from rigid opaque materials to rubber like materials to clear and translucent materials to Simulated Polypropylene and specialized photopolymers for 3D printing in the dental and medical industries.

Below video shows PolyJet technology in detail

Laminated object manufacturing (LOM)

Laminated object manufacturing (LOM) is a rapid prototyping (additive manufacturing) technology developed by Helisys Inc. In this technology, layers of adhesive-coated paper, plastic or metal laminates are successively glued together and cut to shape with knife or laser cutter. Objects printed with this technology can be additionally modified by machining or drilling after printing. Typical layer resolution for this process is defined by the material feedstock and usually ranges in thickness from one to a few sheets of copy paper. These printers use thousands of standard A4 sheet papers that are cut by the machine and then glued together in order to produce the finished product.

Below video shows Laminated Object Manufacturing technology in detail

Electron beam melting (EBM)

Electron beam melting (EBM) is a type of additive manufacturing for metal parts. The main difference between EBM and SLS is that EBM uses an electron beam as its power source as opposed to laser in SLS technology. EBM technology manufactures parts by melting metal powder layer by layer with an electron beam in a high vacuum. In contrast to sintering techniques, both EBM and SLM achieve full melting of the metal powder. In EBM, the final product has a higher quality and hence making it a true replacement of standard manufacturing techniques.

Below video shows Electron Beam Melting technology in detail

STL Format

STL is an abbreviation of the word Standard Tessellation Language(STL). 3D printers use this file format for transforming a 3D image to a 3D model. The STL file format explains the geometry of a certain image. So it becomes easier for the printer to transform the image into model. These are basically open file standards and are widely used for Computer Aided Manufacturing (CAM) or rapid proto-typing.

Image Credit: Keith Kissel (flickr handle: kakissel)