A heatsink is a device that is used to direct the heat of the CPU to the other parts of the computer. This is done to preserve the equipment from damage and keep the data intact. Metals make very good heatsinks and they are in various sizes and prices. Maintaining the temperatures of electronic devices is as crucial as maintaining our body temperatures.

There are two upcoming projects in the US that are aimed at improving the quality of heatsinks by using the 3D printing technology. Researchers at the Oak Ridge National University are working to experiment that the 3D printed aluminum might be a better option for making a heatsink than the traditional metals. Experts at the University of Tennessee Knoxville are engaged in designing algorithms that can be used in metals customized by 3D printing to make viable heatsinks.

The two research are linked and aim at generating better raw materials that can dissipate heat and be used for electronics. The research at ONRL concluded that they could make components that could offset heat well. The researchers also stated that with increased intensities of power in the electronics, they would need better heatsinks, and additive manufacturing could be combined with thermal annealing to meet this goal.

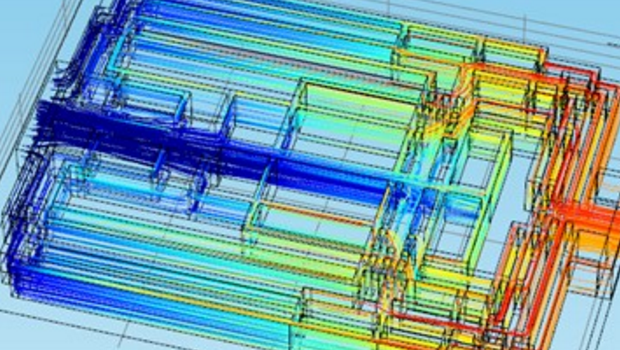

Experiments were conducted to establish the theory that 3D printed metals were better options for heatsinks. Next was the designing of the heat sinks. Designs were made of aluminum, which had grooves, and experiments were conducted with water flowing between these grooves. They added the temperature of the hottest part of the heatsink into a force that was required to achieve the water flow.

Cold water was routed from the transistors in the front row to those behind. The research team favors the cooler components in this respect and many more changes have to be made to achieve correct results.

Source: 3dprint.com