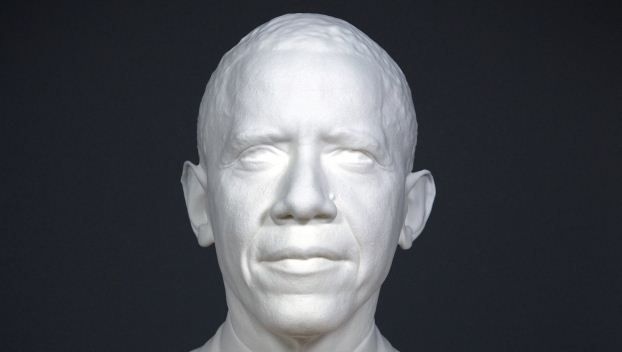

‘Selfies’ are the current trend and no matter our gender and age group we belong to, we all love to take selfies. So far, selfies mean the 2D pictures. Taking this concept of selfies to the next level, 3D selfies have now become a fad. But it is not common that 3D scanning and 3D printing are used to make one of the world’s famous and influential political leaders, Mr. Barack Obama, the President of the United States. Obama is one amongst the powerful and forward thinking leaders of the world today and he is widely recognized person. 3D tech was used to create an emblematic 3D printed bust of Obama for the first time ever. The portraits are on display in the commons gallery of Smithsonian Castle Museum till this month end.

Two years ago, Adam Metallo and Vincent Rossi from Smithsonian Institution had a vision named ‘Next Generation 3D Portraiture: A Digital Life Mask of President Obama’. Later, OSPT (The White House Office of Science and Technology Policy) heard about the concept and had invited the team to produce a bust in actual likeness of the President. With the help of University of Southern California (USC) Institute for Creative Technologies, who used their Mobile Light Stage, the Smithsonian team spent quite some time taking pictures of the President.

Primarily, the USC assembled the Mobile Light stage that includes about fifty light sources, eight high quality digital single lens reflective cameras with an augmentation of additional sources to the system of a top-down panoramic view. The scanning system captured about eighty pictures in a second.

The whole process, from the start to the finish, took about seven minutes of the President’s time. A vast amount was read and converted into a deep resolution digital model and this was done with the Mobile Light Stage and hand-held three dimensional scanners. The bust is indeed the highest resolution digital model produced with about 15,000,000 triangles.

The team form Smithsonian said that as their stated goal was to produce a full bust of President Obama they augmented the light stage technology with an additional process to capture a part of the torso, the top and the back of the head. For the second stage of the portrait, they asked Obama to sit still while Vince and Adam circled him with hand-held scanners. These scanners captured a video of light pattern which deforms when it was projected on a subject. Based on the deformation, the algorithms reconstructed this data into color 3D geometry. They added that as the Adam and Vince proceeded with the scan, those who were in the room saw the image emerging on the laptop screens that were connected to the scanners. A hand-held photography ensured that the detail that was difficult to resolve was not lost.

Selective Laser Sintered 3D print was used to print the final digital render of Obama. After the scans and photographs taken by the team, they analyzed and reconciled the data. The team checked through each of the many detailed images individually for optimal rendering and missing data area and this was a whole night process.

The next day, the team transferred this data to 3D software company Autodesk and they put together a 3D model by normalizing the unified color information and registering various data source geometrics into single space. The last stage included the addition of the output models plinth base to create the bust profile. After two days, the 1:1 scale final bust was transferred to 3D systems which used nylon powder based SLS (Selective Laser Sintering) to 3D print the bust that is nineteen inches tall. The printing took forty-two hours and the result is pretty amazing.

Mr Barack Obama was very impressed with the final bust and it was first displayed at the White House MakerFaire. Currently it is in Smithsonian Museum and is on display from 2nd to 31st December.

The President, in 3D