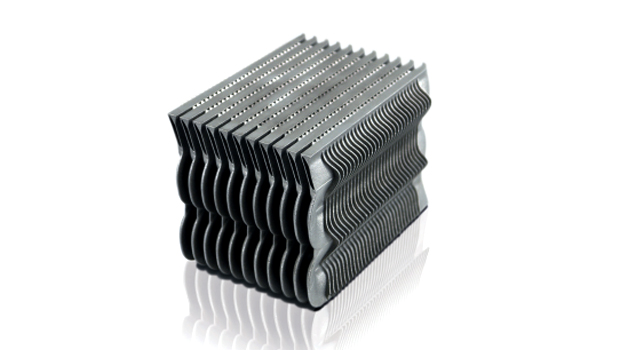

AlSi10Mg is a typical casting alloy with good casting properties and is typically used for cast parts with thin walls and complex geometry.

Material Composition

Al (balance)       Si (9.0 – 11.0 wt-%)

Fe (<= 0.55 wt-%)       Cu (<= 0.05 wt-%)

Mn (<= 0.45 wt-%)       Mg (0.2 - 0.45 wt-%)

Ni (<= 0.05 wt-%)       Zn (<= 0.10 wt-%)

Pb (<= 0.05 wt-%)       Sn (<=. 0.05 wt-%)

Ti (<= 0.15 wt-%)