Thanks to the huge publicity wave from the last 2-3 year, we all have started understanding the concept of 3D – three dimensions which mean length, breadth and height of an object. Now, researchers are trying to add a fourth dimension to this. 4D refers to models that represent the fourth dimension of any materials i.e. change. So 4D printer means printer that can create objects which can transform over time and in some cases they can self assemble.

Towards turning this dream into reality a collaborative effort is being made by Stratasys’ Education, R&D departments and MIT’s Self-Assembly Lab. This venture is being led by Skylar Tibbits who is a trained architect, a computer scientist as well as an artist. This research is focused on developing self-assembly technology for large -scale structures that can exist in the physical environment.

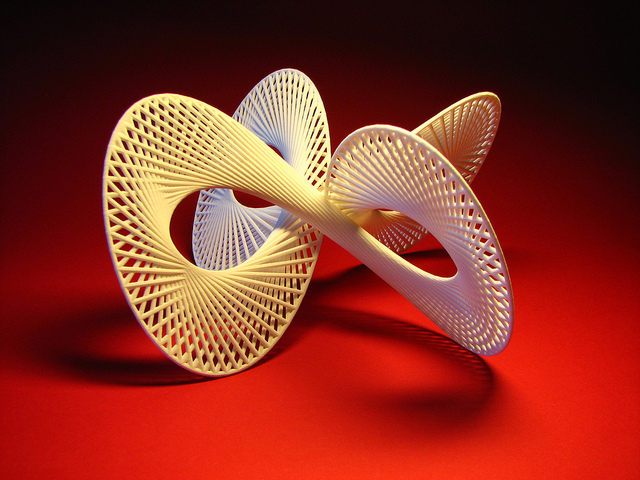

With the help of Stratasys’ Connex technology a single print with multi-material features can transform from any 1D strand into 3D shape, 2D shape into a 3D shape or replicate one 3D model to another 3D model. The Connex multi-material 3D printing technology is an important part of 4D printing which is used extensively. This machine allows the researchers to program different material properties into each of the other particles of the designed geometry. The self assembly process is activated by the harnessing of the different water absorbing properties of the material. With water as the activation energy, this technique has a lot of possibilities for embedding programmability and simple decision making into non electronic base material.

He also adds that his lab has been closely working with a number of industry partners on ways they could incorporate the concept of 4D in their businesses. As of now Tibbits sees this technology revising the furniture or the sportswear industry. To this he gives the example of sneakers that could change shape and functions according to the change in conditions. He says that “If I start running, [the sneakers] should adapt to being running shoes. If I play basketball, they adapt to support my ankles more. If I go on grass, they should grow cleats or become waterproof if it’s raining. It’s not like the shoe would understand that you’re playing basketball, of course, but it can tell what kind of energy or what type of forces are being applied by your foot. It could transform based on pressure. Or it could be moisture or temperature change.” Making all this happen on a human scale is very challenging particularly in more traditional industries such as construction says Tibbits. But he feels that there is potential of this technology in all the industries. For instance, he sees a future for what he calls “adaptive infrastructure” in space.

But this still is something that has not turned into reality, the reality at present stands at this technology not being commercially available. This is undoubtedly the beginning of an entirely new innovative world of manufacturing with minimum energy. 4D printing is the first technology that offers smart objects which is quite exciting. This surely is a gigantesque shift in our understanding of structures, which until today have been objects that have been static and rigid. It’s a mind boggling experience to imagine what this technology could do to industries like aerospace, automotive, building industries etc which could soon become dynamic, adaptable and could change according to the demand.