There has been a phenomenal growth in the use of 3D printing technology to develop new products in the healthcare sector. It initially occupied a minute segment of the 3D print technology and has now become a full grown industry with great potential. There have been developments in the prosthesis manufacturing, bioprinting, and medical implants, but there still lies tremendous scope in this area and is expected to grow leaps and bounds till 2020.

As per the recent findings of the IndustryArc, the growth in the health care 3D printing sector has led to the bifurcation of this industry into various categories and segments. The technology segment has subcategories like fused deposition modelling (FDM), Stereolithography, laser beam melting (LBM), and electron beam melting(EBM), to name a few. The raw materials like metals, resin, biological materials, and more, used in this technology also occupy an entire section.

Based on the findings of the IndustryArc, the worldwide medical 3D print market had revenues worth $487 million in 2014 and is expected to grow at the rate of 18.3% annually till 2020. This growth could be attributed to the adoption of the 3D print technology in the numerous medical applications. The sectors that have seen huge growths in 3 D print technologies are dental and medical implants, which use metal and ceramic materials for making 3D dental crowns and varied types of biomaterials, which are used by the health research industry.

The material segment of the medical 3D print technology earned revenue of $284.7 million in 2014 and is expected to grow further at the pace of 19.1 % till 2020. The materials used in this segment are metal, plastic, ceramics, donor cells, bone cement and other biomaterials. These raw materials are extremely expensive but with the widespread use and technological advancements, the costs are expected to decline.

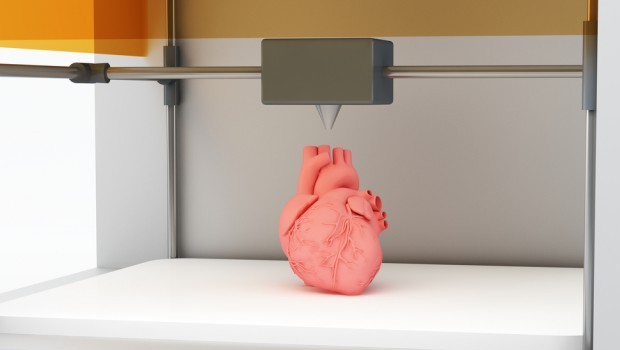

There is a growing demand for customised patient products for orthopaedics and maxillofacial surgeries. Further, research is ongoing in the field of tissue engineering and it is predicted that the tissues evolved from bio 3D printing could be used in the manufacture of new organs and tissues for transplants. Government subsidies and medical research grants would go a long way in reducing 3D medical technology costs.

North America is the largest market for 3D print health care and occupied 39.7% of the market share in 2014. It is followed by Europe and then APAC (Asia Pacific) subsequently. The Asia Pacific market is the fastest growing market with a growth rate higher than North America and Europe.

As per the IndustryARC market research reports, the companies engaged in medical 3D applications and products are 3D systems, Stratasys, Digilab, MicroFab Technologies, nScrypt, Envision TEC, Invetech, and Tevido BioDevices.

Learning and anatomical replicas

While the focus has been on 3D printing implants and medical devices used by patients, one of the largest areas of application is the fabrication of anatomical replicas. Doctors are currently utilizing models produced by 3D printing from patient scan data to enhance the diagnosis of illnesses, clarify treatment decisions, plan, and, in some cases, even practice chosen surgical interventions in advance of the actual treatments. The models enable doctors to understand patient anatomy that is difficult to visualize, especially when using minimally invasive techniques. Models also assist in precisely sizing medical devices. Doctors can also utilize the models to explain an upcoming medical procedure to patients and their families and to communicate the surgical steps to their colleagues.

To help reduce cost, some facilities have developed procedures where surgeons practice and plan operations on cheap mannequins that are transplanted with patient-specific 3D printed models. Surgeons can now obtain an even better understanding of precisely how a procedure needs to be performed right down to the touch and feel of the distinctive parts of a patient’s anatomy. FDM printers are perfect for geometrically basic surgical models that don’t require a high level of detail or include intricate features.

Surgical tools

Doctors use tools to assist in surgery. These were conventionally made of titanium or aluminium. With 3D printing in healthcare, doctors can create tools that accurately follow a patient’s unique anatomy. 3D printed tools are used to make the placement of restorative treatments (screws, plates and implants) more precise, resulting in better postoperative results. The FDM 3D printing technology is ideal for iterative, low-cost prototyping to optimize the design of a tool.

Prosthetics

In the United States close to 200.000 amputations are performed each year. Replacement or alterations can be time consuming and expensive. Because prosthetics are such personal items, each one has to be custom-made or fit to the needs of the wearer. 3D printing changed all this and is now regularly being used to produce patient specific components of prosthetics that match perfectly with the user’s anatomy.

Source: 3Dprint.com