It is a well-known fact that the emerging technology of 3D printing is creating wonders in every field but this one is all set to blow your minds. With the latest achievement of Rocky Tuan who is the director of the Center for Cellular and molecular Engineering and professor and executive vice chairman for orthopedic research at the university of School of Science it has become possible to create artificial cartilage with human cells. This research was carried out in order to find the cure for degenerative joint disease and similar joint-related ailments found in people but later it found its application for soldiers who suffer with similar injuries.

Osteoarthritis has always been difficult to be identified at its early stages because people often notice this ailment growing when it’s too late. Tuan says, ”There is therefore a great need for an osteochondral ‘tissue-on-a-chip’ system that will permit the study of both how the disease begins and progresses, and to discover potential therapeutic agents”.

Tuan’s Journey to create artificial cartilage using 3D Printing

In order to achieve the creation of artificial cartilage, there were three key elements that are to be targeted, namely, stem cells, biological factors and scaffold. Tuan managed to get all three elements on chip by molding thin layers of stem cells and then treating them with a solution that has the property of retaining its shape and providing growth factor. He did not use the common 3D printing methods that are believed to damage cells. Instead, he utilized the novel approach of 3D printing that uses visible light that help preserve human cell viability.

Tuan and his team is working continuously towards combining the 3D printing technology with novel nanofiber spinning method to offer stronger scaffold that can replicate human cartilage to a greater extent.

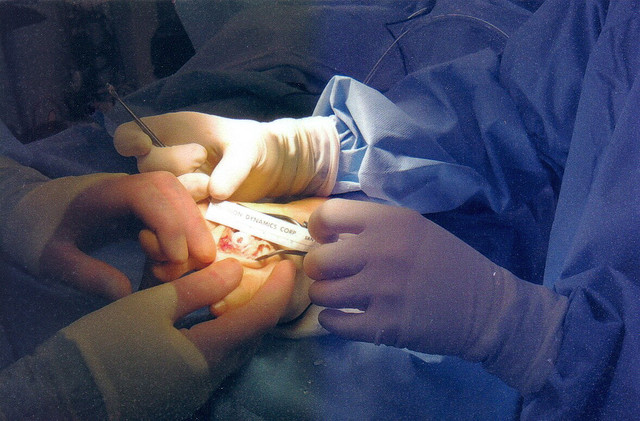

Image Credit: Michael (a.k.a. moik) McCullough (flickr handle: ex_magician)