Rapid prototyping is a way to quickly fabricate and visualize a solid model of a part or assembly using 3D CAD data. In other words, it is a fast and more cost-effective method for creating prototypes for product development.

It helps for a multitude of uses like functional testing, tooling, moulds, visualization and as a proof of concept. Deeper uses of Rapid Prototyping include decreased development time, reduce costly mistakes, give an effective communication to the end user and allow multiple variants if the product.

[button size=medium style=round color=red align=left url=https://www.think3d.in/3d-printing-on-demand-place-order/ text=”Get Started Now!”][/button]

[button size=medium style=round color=black align=none url=https://www.think3d.in/contact-us-at-think3d/ text=”Contact Us!” target=”_blank”][/button]

Steps in Rapid Prototyping Methodology

- CAD Model Preparation as per the required design

- Creation of 3D print ready file, in the form of .STL file

- Use of appropriate rapid prototyping/ 3D printing methodology

- Model finishing and post processing

Rapid Prototyping Services for customers across India

Rapid Prototyping Division of think3D prides itself in its ability to provide multiple Rapid Prototyping methodologies providing material options, involving multiple techniques to give the best possible outcome to its clients looking for good quality rapid prototyping services in India at a reasonable price. Our clientele come from a wide spectrum of industries including engineering, automobile, healthcare, manufacturing, construction, ranging from large corporations to nimble startups and even individual hobbyinsts.

Depending on the application, timelines and finish requirements, we use the following rapid prototyping techniques to bring the part to life.

Check Rapid Prototyping Techniques – Comparison for more details.

[button size=medium style=round color=red align=left url=https://www.think3d.in/3d-printing-on-demand-place-order/ text=”Get Started Now!”][/button]

[button size=medium style=round color=black align=none url=https://www.think3d.in/contact-us-at-think3d/ text=”Contact Us!” target=”_blank”][/button]

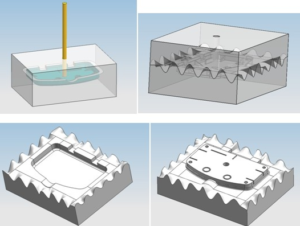

Vacuum Casting

Vaccuum casting technique helps in getting a small quantity of plastic pieces with the quality of injection molded components. The method uses cast silicone molds made with the help of a master model created using stereolithography (SLA) typically. Silicone material is cast around the carefully developed master model, partially under vacuum in order to avoid air bubbles being trapped in between the master and silicone. The surface quality and the dimensional accuracy of the master is a determining factor for the quality of vacuum casted components. After curing, the mold is cut according to the parting planes and the master is removed, leaving a cavity to make copies.

casting technique helps in getting a small quantity of plastic pieces with the quality of injection molded components. The method uses cast silicone molds made with the help of a master model created using stereolithography (SLA) typically. Silicone material is cast around the carefully developed master model, partially under vacuum in order to avoid air bubbles being trapped in between the master and silicone. The surface quality and the dimensional accuracy of the master is a determining factor for the quality of vacuum casted components. After curing, the mold is cut according to the parting planes and the master is removed, leaving a cavity to make copies.

Materials options provided by us: ABS, Rubber, PP

Object Characteristics: Good Surface finish and strength for prototyping and enduse

Typical Applications:

[button size=medium style=round color=red align=left url=https://www.think3d.in/3d-printing-on-demand-place-order/ text=”Get Started Now!”][/button]

[button size=medium style=round color=black align=none url=https://www.think3d.in/contact-us-at-think3d/ text=”Contact Us!” target=”_blank”][/button]

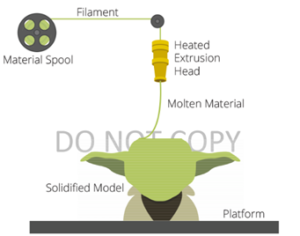

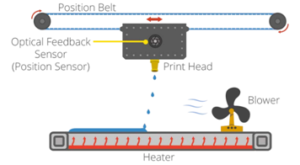

Fused Deposition Modeling (FDM)

The Fused Deposition Modeling (FDM) process creates  three-dimensional solid objects directly from 3D CAD model data. The FDM process starts with importing an STL file of a model into a pre-processing software. The slicing software generates a gcode comprising machine level instructions that are fed to a 3D printer. The temperature-controlled extrusion head, which moves as per the gcode instructions, is fed with thermoplastic modeling material that is heated to a semi-liquid state. The head extrudes and directs the material with precision in ultrathin layers onto a fixtureless base. The result of the solidified material laminating to the preceding layer is a plastic 3D model built up one strand at a time. Once the part is completed, the support columns are removed and the surface is finished. Depending on the requirement, post processing is possible for required finish.

three-dimensional solid objects directly from 3D CAD model data. The FDM process starts with importing an STL file of a model into a pre-processing software. The slicing software generates a gcode comprising machine level instructions that are fed to a 3D printer. The temperature-controlled extrusion head, which moves as per the gcode instructions, is fed with thermoplastic modeling material that is heated to a semi-liquid state. The head extrudes and directs the material with precision in ultrathin layers onto a fixtureless base. The result of the solidified material laminating to the preceding layer is a plastic 3D model built up one strand at a time. Once the part is completed, the support columns are removed and the surface is finished. Depending on the requirement, post processing is possible for required finish.

Materials options provided by us: PLA, ABS, Nylon, Wood, HIPS, PMMA

Object Characteristics: FDM parts will be the cheapest to be created and typically have good strength, and a range of engineering thermo plastics are available in this technique. The drawback include less speed, surface finish, slightly lesser accuracy compared to other 3D printing techniques. Postprocessing with Acetone/ Putty is applicable for achieving smoother watertight finish and . Painting is an option for monocolour structures

Typical Applications:

[button size=medium style=round color=red align=left url=https://www.think3d.in/3d-printing-on-demand-place-order/ text=”Get Started Now!”][/button]

[button size=medium style=round color=black align=none url=https://www.think3d.in/contact-us-at-think3d/ text=”Contact Us!” target=”_blank”][/button]

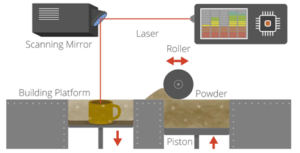

Laser Sintering (SLS/ SLM)

Laser sintering and laser melting are interchangeable terms that refer to a laser based 3D printing process that works with powdered materials. In the Selective Laser Sintering technique, successive powder layers are spread on top of each other, on which, a CO2 laser beam which is computer-controlled as per the Cad data, scans the surface and selectively binds together the powder particles of the corresponding cross section of the product in a process called sintering. The layered material consists of powder with particle sizes in the order of magnitude of 50 µm. Laser sintering can process plastic and metal materials, although metal sintering does require a much higher powered laser and higher in -process temperatures.

Laser sintering and laser melting are interchangeable terms that refer to a laser based 3D printing process that works with powdered materials. In the Selective Laser Sintering technique, successive powder layers are spread on top of each other, on which, a CO2 laser beam which is computer-controlled as per the Cad data, scans the surface and selectively binds together the powder particles of the corresponding cross section of the product in a process called sintering. The layered material consists of powder with particle sizes in the order of magnitude of 50 µm. Laser sintering can process plastic and metal materials, although metal sintering does require a much higher powered laser and higher in -process temperatures.

Materials options provided by us: PA Nylon (white), Stanless Steel, aluminium

Object Characteristics: In this process is that the powder bed serves as an in-process support structure for overhangs and undercuts, and therefore complex shapes that could not be manufactured in any other way are possible with this process. Parts produced with this process are much stronger than with SL or DLP, although generally the surface finish and accuracy is not as good. SLS parts have much higher better accuracy than FDM

Typical Applications:

[button size=medium style=round color=red align=left url=https://www.think3d.in/3d-printing-on-demand-place-order/ text=”Get Started Now!”][/button]

[button size=medium style=round color=black align=none url=https://www.think3d.in/contact-us-at-think3d/ text=”Contact Us!” target=”_blank”][/button]

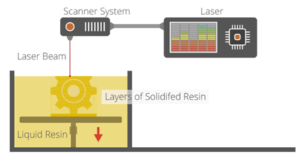

Stereolithography

Stereolithography is the first and now one of the most widely used rapid prototyping techniques for prototyping. In a SLA process, a thin layer of photopolymer (usually between 0.05-0.15 mm) is exposed above the perforated platform. The UV laser hits the perforated platform, “painting” the pattern of the object being printed. The UV-curable liquid hardens instantly when the UV laser touches it, forming the first layer of the 3D-printed object. Once the initial layer of the object has hardened, the platform is lowered, exposing a new surface layer of liquid polymer. The laser again traces a cross section of the object being printed, which instantly bonds to the hardened section beneath it. This process is repeated again and again until the entire object has been formed and is fully submerged in the tank. The platform is then raised to expose a three-dimensional object. After it is rinsed with a liquid solvent to free it of excess resin, the object is baked in an ultraviolet oven to further cure the plastic.

Stereolithography is the first and now one of the most widely used rapid prototyping techniques for prototyping. In a SLA process, a thin layer of photopolymer (usually between 0.05-0.15 mm) is exposed above the perforated platform. The UV laser hits the perforated platform, “painting” the pattern of the object being printed. The UV-curable liquid hardens instantly when the UV laser touches it, forming the first layer of the 3D-printed object. Once the initial layer of the object has hardened, the platform is lowered, exposing a new surface layer of liquid polymer. The laser again traces a cross section of the object being printed, which instantly bonds to the hardened section beneath it. This process is repeated again and again until the entire object has been formed and is fully submerged in the tank. The platform is then raised to expose a three-dimensional object. After it is rinsed with a liquid solvent to free it of excess resin, the object is baked in an ultraviolet oven to further cure the plastic.

Materials options provided by us: Clear Resin, white Resin, Castable Resin, tough Resin, Flexible Resin

Object Characteristics: Stereolithography is generally accepted as being one of the most accurate 3D printing processes with excellent surface finish. However limiting factors include the post -processing steps required and the stability of the materials over time, which can become more brittle.

Typical Applications:

[button size=medium style=round color=red align=left url=https://www.think3d.in/3d-printing-on-demand-place-order/ text=”Get Started Now!”][/button]

[button size=medium style=round color=black align=none url=https://www.think3d.in/contact-us-at-think3d/ text=”Contact Us!” target=”_blank”][/button]

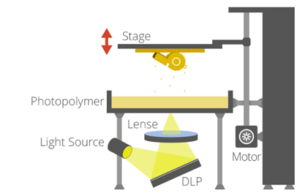

Digital Light Processing (DLP)

It is a similar process to stereolithography in that it is a 3D printing process that works with photopolymers. The major difference is the light source. DLP uses a more conventional light source, such as an arc lamp with a liquid crystal display panel, which is applied to the entire surface of the vat of photopolymer resin in a single pass, generally making it faster than SL.

Also like SL, DLP produces highly accurate parts with excellent resolution, but its similarities also include the same requirements for support structures and post-curing. However, one advantage of DLP over SL is that only a shallow vat of resin is required to facilitate the process, which generally results in less waste and lower running costs.

Materials options provided by us: Clear Resin, Castable Resin, tough Resin

Object Characteristics: Same as SLA

[button size=medium style=round color=red align=left url=https://www.think3d.in/3d-printing-on-demand-place-order/ text=”Get Started Now!”][/button]

[button size=medium style=round color=black align=none url=https://www.think3d.in/contact-us-at-think3d/ text=”Contact Us!” target=”_blank”][/button]

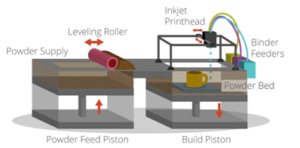

3D Printing (Binder-jetting or color jet printing)

3D printing or colour jet printing uses standard inkjet printing technology with additional dimension. Here, the 3D printer moves a print head to spray inkjets over a bed of powder, instead of feeding paper (as in a typical 2D Printer)

3D printing or colour jet printing uses standard inkjet printing technology with additional dimension. Here, the 3D printer moves a print head to spray inkjets over a bed of powder, instead of feeding paper (as in a typical 2D Printer)

In this technique, parts are created layer by layer by depositing a liquid binder onto thin layers of powder which spread uniformly on a build platform using roller mechanism that is fed with powder from a feed piston. The inkjet print heads then move on to the powder layer, and start printing the cross-sectional area as per the design data, binding the powder together. A piston then lowers the build platform by 0.1 mm, and a new layer of powder is spread on top. The print heads apply the data for the next cross section onto the new layer, which binds itself to the previous layer. This 3D Printing process is repeated for all of the layers until the physical model is created.

Materials options provided by us: PA Nylon (white)

Object Characteristics: Same as SLA

Typical Applications:

[button size=medium style=round color=red align=left url=https://www.think3d.in/3d-printing-on-demand-place-order/ text=”Get Started Now!”][/button]

[button size=medium style=round color=black align=none url=https://www.think3d.in/contact-us-at-think3d/ text=”Contact Us!” target=”_blank”][/button]

Inkjet: Material Jetting

In this 3D printing process, in contrast with binder jetting, the actual build materials (in liquid or molten state) are electively jetted through multiple jet heads (with others simultaneously jetting support materials). However, the materials tend to be liquid photopolymers, which are cured with a pass of UV light as each layer is deposited.

In this 3D printing process, in contrast with binder jetting, the actual build materials (in liquid or molten state) are electively jetted through multiple jet heads (with others simultaneously jetting support materials). However, the materials tend to be liquid photopolymers, which are cured with a pass of UV light as each layer is deposited.

Object Characteristics: The nature of this product allows for the simultaneous deposition of a range of materials, which means that a single part can be produced from multiple materials with different characteristics and properties. Material jetting is a very precise 3D printing method , producing accurate parts with a very smooth finish.

[button size=medium style=round color=red align=left url=https://www.think3d.in/3d-printing-on-demand-place-order/ text=”Get Started Now!”][/button]

[button size=medium style=round color=black align=none url=https://www.think3d.in/contact-us-at-think3d/ text=”Contact Us!” target=”_blank”][/button]

For more Details/ Estimate, fill in your details