Imagine if you could replicate a replicator or a machine creates a copy of an object! Sounds awesome right? The RepRap is the very first self replicating machine which is capable of printing plastic objects. Rep Rap is the abbreviated version of the idea that lies behind this technology which is Replicating Rapid Prototype. The RepRap itself is made of plastic and it also prints in plastic. So, the RepRap replicates itself by making a kit. This kit is user friendly and anyone can assemble it in a matter of minutes. This means that if you have this machine you can print another machine out of it and gift it to a friend!

The founder of this amazing machine, Dr. Adrian Bowyer is also the head of this movement which is popularly known as the RepRap movement. This movement aims to circulate low cost 3D printers among the masses. The RepRap can be considered as the first low-cost 3D printer. The idea of creating a printer that was designed to popularize the technology of 3D printing among the masses came to Bowyer when the University of Bath in England got its first 3D printer. Bowyer has been using this machine since 2005. When Bowyer first saw the 3D printer he felt that the technology of 3D printing was exceptional but the price rendered to buy the device was very steep. According to Bowyer the first time he saw the machine, he felt: ‘This is really neat technology, pity that it costs so much money’, when I looked at how they worked it seemed there was nothing much in there that was worth £30,000. I reckoned that I could probably do it for a few hundred pounds, and as it turns out I was right.” This is when he decided to make a 3D printer that was low on cost, could print in plastic and also replicate itself. The first RepRap replicator was named Darwin which was out in the market way back in 2007. Bowyer kept the source design open to all so that anybody could build their own version of the machine.

The working of the machine is quite similar to the process that is employed by most 3D printers. RepRap printers print typically by layering molten plastic onto a base. The time consumed to build a small plastic joint takes about 30 minutes. The type of plastic used in the machine is ABS, Polylactic acid (biodegradable plastic derived from plants), Nylon (possibly not all extruders capable), HDPE and similar thermo polymers. These RepRaps can be customized so the material that is being used in the machine can also be changed. In the past, people have used materials like clay and ceramics in their RepRaps. The machine in the near future is expected to use different types of materials like metals and rubbers at once. Once this is accomplished complex objects like cell phones, laptops etc can be fabricated in matter of hours.

So, by this it is clear that the RepRaps are not only cheap 3D printers but are also all set to be omnipresent in the constant changing world of technology. The father of the RepRap- Bowyer aims to make the machine so useful that people will be eager to build new copies of this machine for themselves. Bowyer says, “I have made about 300 machines for other people and my co-workers in my company have made getting on for 1,000. You don’t need very many people making hundreds of machines for there to be an awful lot of machines out there.” This machine at present can print around half of the parts except for the nuts and bolts that are required to set this machine up but according to experts the machine would print 90% of the parts by itself in the next five to six years.

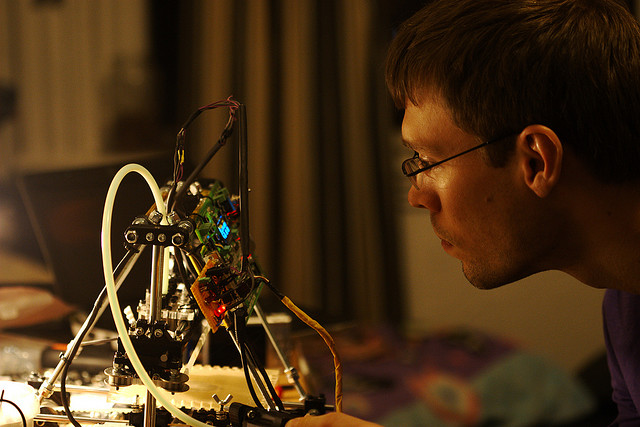

The assembling of the machine could be complicated as bolting together the scaffolds, connecting the print heads and wiring it up requires some expertise in electronics, computing or engineering. To help those who do not have any firsthand experience in setting up a printer is an online community that comprises of wikis, forums and chat channels which provide information on how to build, maintain and improve the machine.

Taking print outs from the machine is quite simple, users can download the blueprint of the object from the internet or develop a blueprint themselves and drop it into one of the open source packages like Skeinforge, Slic3r, pronterface, Cura or Repetier host, which format the blueprints for the RepRap and then sent it to the machine and press the print button. Within a few minutes the desired object will be printed.

Today there are almost 20,000 people who are using this RepRap machine and also the schematics which are freely available online. Many people and groups have taken the design and have created successful low cost 3D printers. Among such organization are the now big shots of 3D printing industry such as MakerBot and Bits from Bytes. The RepRaps have definitely come along way now, with the introduction of RepRaps in schools by GADGETS3D. GADGETS3D has introduced a new RepRap Printer G3D which is small in size and also small on the pockets of many. It has been specially designed for schools, small businesses and individual customers. The name of this project is “3D Printer in every school”, for $245 each school will be able to buy these printers along with a special set of educational kit. Slowly the RepRaps are capturing the market.

The ultimate goal of the team of this project is to produce a self replicating device for everybody by giving minimal stress on the pockets of people. The team wants to generate something which is like a desktop manufacturing system so that anyone can print the objects that are used in everyday life. The replicating nature of the RepRap could bring about a huge change in the design and manufacturing of consumer products. The project surely is a revolutionary step taken to bring this technology to the common people but the negative side of this technology cannot be neglected. If the RepRap becomes a common household item then a major setback will be faced by the manufacturing industry as the RepRap project aims to amalgamate different materials so that a complex object can be printed will ruins the market for many.

Some popular variants of RepRap 3D printers include Prusa I3, Mendel, Darwin, Huxley, Prusa Mendel, Printrbot, Simpson, Wallace, Wilson, Mendelmax etc

Image Credit: Mika (flickr Handle: soulfish)