design for manufacturing

- Design For Manufacturing is the most crucial exercise any product company should do before actual manufacturing for the product. At THINK3D, we offer free detailed DFM analysis. Our DFM analysis go beyond just manufacturing. We also provide most optimal materials, price estimates and recommended suppliers for manufacturing the product.

DESIGN FOR MANUFACTURING ANALYSIS

DFM is “the most important” exercise any product developer should do before going for manufacturing. Once DFM is perfect, rest everything is just a cake walk. With more than 8 years of rich experience in product development and low volume production, we mastered the art of manufacturing using various manufacturing technologies namely 3D Printing, CNC Machining, Injection Molding, Sheet Metal Fabrication, Die Casting. With a team of experts and rich experience in our kitty, we are now offering DFM analysis to our customers.

Quick Analysis

Upload files and get detailed analysis within 24-48 hrs

Technical Competency

Technically qualified team in various mfg. technologies

Competitive Pricing

Basic analysis is free and low cost for detailed analysis

NDA & IP Protection

All data is protected with a strong NDA & IP protection

we analyse on

Process

Manufacturing process is the first aspect to look into when designing a product. Different processes have different MoQ requirements, tolerance, materials, price points, secondary technologies and assembly requirements. We look in product design, industry, product stage and accordingly suggest the right process to manufacture the product.

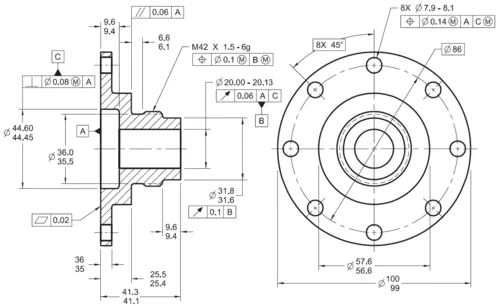

Design

Good design is essential for good product. The actual drawing of the part should conform to good manufacturing principles for the manufacturing process chosen. For example, in injection molding the following principles apply – constant wall thickness, appropriate draft, texture, ribs, simple transitions from thick to thin features, no undercuts or features that require side action, most optimal tolerances.

Material

It is also very important to select the right material for the product. Right material depends on the required properties for the part, physical environment it is placed in, cost & quantity. Certain properties to consider during DFM include mechanical properties, chemical properties, optical properties, thermal properties, color, electrical properties, flammability.

Compliance / Testing

All products must comply with safety and quality standards. Sometimes these are industry standards, others are third-party standards and some are internal, company-specific standards.

Environment

The product must be designed to withstand the environment it will be subjected to. Different materials have different properties like electrical conductivity, corrosion resistance and so on. Make sure the product is designed to function properly under its normal operating conditions.

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, THINK3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Jay Krishnan

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL

learning center

What is Design For Manufacturing (DFM)

3D Printing of Silicon

Frequently Asked Questions

Design for manufacturability (DFM) is the engineering practice of designing products to optimize their manufacturing ease and cost given form, fit, and function requirements. Because manufacturing processes are so numerous and varied, effective design for manufacturability may hinge on very different analyses for different products, including anything from cooling times for molded parts to the type of material or machine selected.

DFA (Design For Assembly) seeks to simplify the assembly to reduce the assembly cost. Applications of DFA principles to product design usually result in improved quality, reliability and reduction in production equipment and part inventory.

DFMA stands for design for manufacture & assembly. DFMA is a combination of two methodologies, namely DFM & DFA which means design of the product for ease of assembly deriving creative ideas at the same time.

Currently, we don’t provide DFA & DFMA analysis in particular. But our regular DFM analysis includes certain elements of DFA & DFMA analysis.

Yes, all the files you upload into the server are highly secure. All the data uploaded is secured by strong NDA & IP protection clauses you accept while placing the request.

Contracting with a service bureau to make your 3D printed parts is a good way to get introduced to the benefits of the technology. You gain the expertise and insight of a 3D printing specialist who can possibly guide you in optimizing the use of the technology for your specific purposes. Your out-of-pocket expenses are usually lower initially since you avoid the up-front expense associated with a printer purchase.

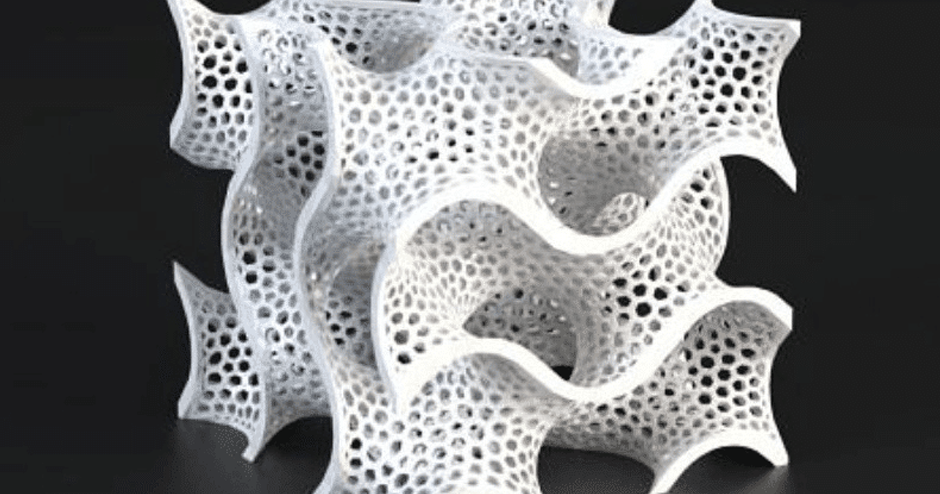

Additive manufacturing shows promise for the defense, energy, aerospace, medical and commercial sectors. Its alternative approach to machining, forging, molding and casting makes it a good choice for rapidly making highly customized parts. The technology also shows promise for creating parts on site, such as at forward-stationed military bases. Because of its potential, many companies are using the technology to get themselves into a position to use it. The growing field of companies using the technology includes makers of machine parts and novelty items.

We’ve been in the business of helping customers solve problems for over 8 years with our 3D printing solutions. We can help you determine what technology is right for your application, whether a printer or a service bureau is more appropriate, as well as answer any questions you might have.

Yes, lots of different companies across a range of industries use additive manufacturing, including the medical industry, aerospace and more. Additive manufacturing is particularly useful for making complex or bespoke parts – whether for a new application or to replace an old part that may no longer be available.