Image Source: 3d natives

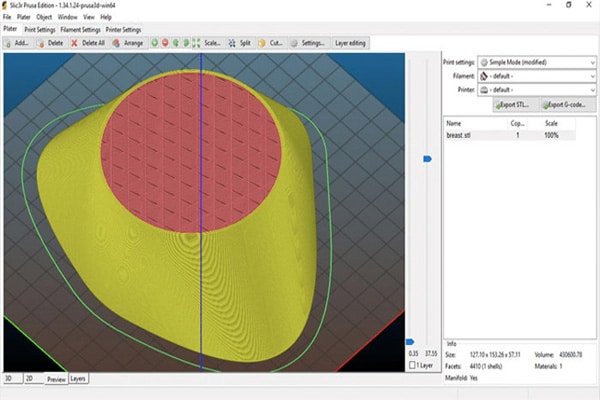

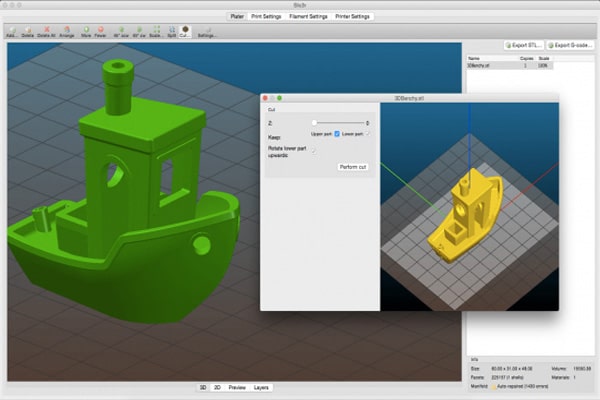

Introduction: A slicer or slicing software acts like a bridge between the 3D model and 3D printer. The task of the slicer is to cut the 3D model into layers. Instructions given to the machine are converted into a special language called G-code. Now let us take a close look at Slic3r software. Slic3r is an open-source software which works with CAD files to generate the G-code. It was launched in 2011 within the Reprap community and is a non-profit project, so it can be downloaded for free. Since its creation, the Slic3r software has been released in 48 official versions. However, the open-source software hasn’t been updated in the last two years, thus the latest version is 1.3, released in 2018.

First Step: To use the software, you must first download it from the official website or via Github. Pre-compiled versions are available for Windows, Mac OS X and Linux. After downloading all you need to do is install Slic3r. Before the first printout it is necessary that your 3D printer is correctly calibrated, as the software and print quality depends on it. For example, if the extrusion speed is not set correctly, the machine will not produce the amount of filament that has been determined.

Slic3r configuration: For the manufacturing process to work optimally, not only must the 3D printer be correctly calibrated, the configuration parameters should also be correct.

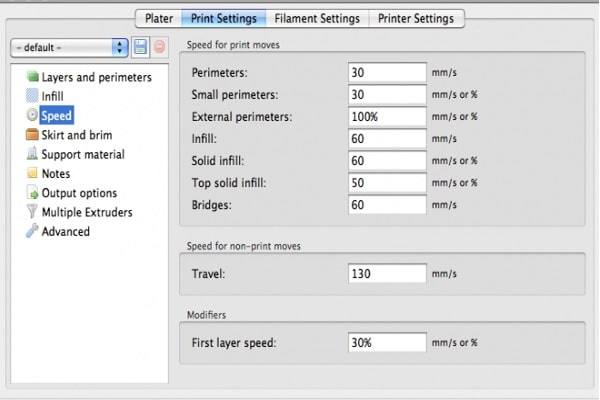

Print settings: Now let us know about the general configuration of the print, which consists of height and perimeter. The layer height represents the thickness of each extruded layer and is influenced by the desired resolution and printing speed. Generally lower layer height results in better print quality. The perimeters are limits of each layer, which is fixed value for all layers. You can also choose infill parameters i.e material used inside the model. This serves as a support for the surfaces. Another group of parameters is speed. Slic3r adjusts the extrusion speed according to the parameters specified by the user.

Filament settings: These are used less frequently. The software will fill the values in the filament settings. You have the possibility to add or update them. These values are related to the setting of diameter, flow rate and temperature. Slic3r can calculate the weight and cost of manufacture.

Conclusion: Slic3r is software for all levels. Another advantage is that the software is free, open-source and compatible with many printers. It allows you to preview the printout but it doesn’t calculate the printing time. If you compare it to Cura which is similar but the regular updates and upgrades make it a desirable slicer. But still Slic3r is still a good option for setting up 3D print jobs.