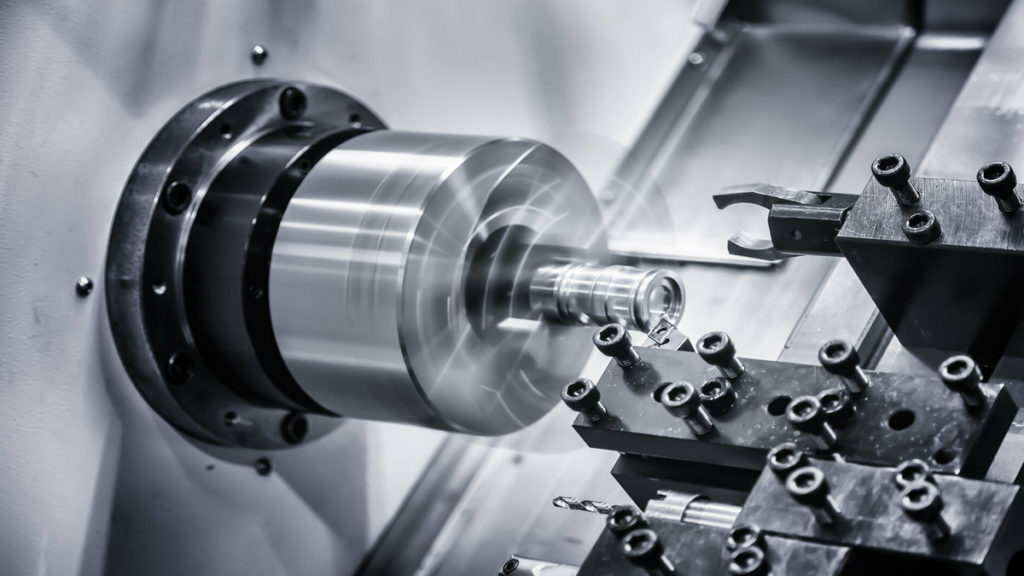

The standard blank refers to a material piece primarily laden to the CNC machining. These materials come in rods for turning or plates for milling purposes in varied sizes. However, both types have different standard sizes. Let us get acquainted with the standard blank dimensions of both the materials that are generally available.

Common Standard Blank Dimensions of Plates!

Plates are generally available in large sheets or as pre-cut to size. These sheets are cut into blank sizes, which limits the plate dimensions while considering the design.

The most common plate piece materials are steel and aluminum, which are easily available in every machine shop. Let us check out the thickness of these standard blank pieces in the form of mm and inches.

| S. No. | Thickness in Inches | Thickness in mm |

|---|---|---|

| 1 | 3/16” | 3 mm |

| 2 | 1/4” | 4 mm |

| 3 | 5/16” | 5 mm |

| 4 | 3/8” | 6 mm |

| 5 | 7/16” | 8 mm |

| 6 | ½” | 10 mm |

| 7 | 5/8” | 12 mm |

| 8 | ¾” | 15 mm |

| 9 | 1” | 20 mm |

| 10 | ½” increase | 25 mm |

| 11 | - | 30 mm |

| 12 | - | 10 mm enhancement thereafter |

Common Standard Blank Dimensions of Rods!

Rods are long stocks that are broken into blanks. The only restricting dimension in the case of rods is their diameter. Just like the plates, rods’ most common materials are steel and aluminum diameters that can easily be available in every machine shop.

Let us check out the diameters of these standard blank pieces in the form of mm and inches.

| S. No. | Diameter in inches | Diameter in mm |

|---|---|---|

| 1 | 1/8” | 3 mm |

| 2 | 3/16” | 4 mm |

| 3 | ¼” | 5 mm |

| 4 | 5/16” | 6 mm |

| 5 | 3/8” | 7 mm |

| 6 | 7/16” | 8 mm |

| 7 | ½” | 9 mm |

| 8 | 5/8” | 10 mm |

| 9 | ¾” | 12 mm |

| 10 | 7/8” | 14 mm |

| 11 | 1” | 15 mm |

| 12 | ¼” enhancement thereafter | 16 mm |

| 13 | - | 20 mm |

| 14 | - | 25 mm |

Essential to Note!

Around 0.3mm to 1.5mm of material is generally eradicated from each side of the piece during machining. So, this needs to be considered while designing the standard blank sizes.

How does THINK3D help?

THINK3D facilitates production of the CNC Machining end-use parts and prototypes within 3 to 4 days. Our team of experts in CNC milling and turning performs the entire process with the desired proficiency and accuracy levels.

So, which material best fits your requirement or delivers proficiency within the budget? Think 3D takes care of it all! With the enhanced proficiency levels, excelling in the field is no longer an issue! Below are the features that separate us from the rest!

1. Technical Competencies

We have a team of proficient professionals having years of experience with definite technical skills.

2. Competitive Pricing

High-quality materials are now accessible at highly competitive pricing with bulk discounts.

3. Quick Online Quote

Get the quote real quick from the professionals. We offer competitive quotes for the requirements with the assurance of higher quality materials.

4. NDA and IP Protection

All the data, information, and designs are stored in a highly secure and confidential manner.

Bottom Line!

Both CNC milling and turning processes require proficiency levels to deliver the appropriate size and accuracy to the materials. Being a preeminent destination in the CNC milling and turning process, THINK3D delivers excellence in the whole field. Based on the appropriate sizing and required materials, one can easily fulfil the customized sizes to cover the need.