Research is ongoing to determine the most effective and viable means to reduce costs in operating the 3D extruder desktop printers. The Radik Delta 3D printer has been launched via crowd funding and is in the stage of prototyping and seems to be the best solution to the problems faced by extruder printers.

Daniel Kurnianto, founder of DK Automation said that the 3D printers can be technically developed to engineer the right design for manufacturing. It makes the processes be more reliable, cost effective and involves low maintenance. He hoped that the technology could be beneficial to businesses.

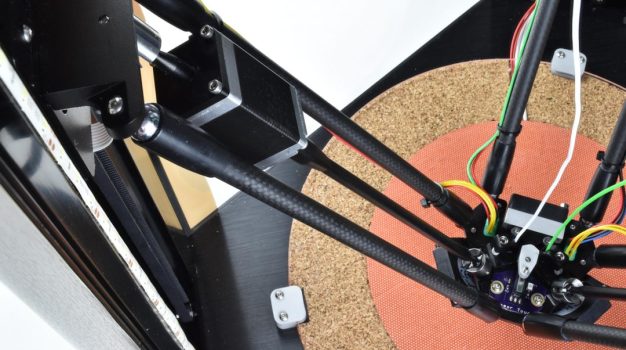

So what are the exclusive features of the Radik 3D printer? It is constructed using all industrial-grade CNC machined parts and involves a simple modular design, a rigid extrusion frame (allowing for higher speed 3D printing). The Radik 3D printer has a patent-pending for Direct Delta Extruder technology designed for high-quality filament control.

The extruder printer uses a remotely located motor, making the print head light and free to move. Although direct drive extruder systems have been prevalent, Bowden extruder systems have their own patent pending systems. This 3D printer technology uses a direct system on a delta 3Dprinter.

Though the extruder system has simple operations and features, yet the built-in dual filament system, heated bed, open-source firmware, self-leveling and fully enclosed casing make the printer a well-equipped device.

Once the crowd-funding commences, it will determine the success of the Radik 3D printer. If the printer has potential and will prove beneficial to the current operating business, it could be a long surviving product that finds its place in the market. That is yet to be seen.

Source: 3ders.org