What Makes Stainless Steel Stainless

Steel is one of the most common materials used in engineering and construction. Steel is found everywhere in millions of items we see in daily life. Of this steel, stainless steel is one of the significant variants that is known for its anti-rust characteristics. Let’s understand stainless steel in terms of its composition and why rust does not form on the surface of stainless steel so that you can decide if stainless steel is a better option for your need.

What is Steel?

Steel is an alloy primarily containing iron with other alloying elements in minor percentage. Pure iron is very soft and brittle hence cannot be used for making usable parts. So carbon is added which gives the strength. Carbon atoms get embedded in the tiny gaps of iron atoms making them less likely to slip one on another under a force or impulse. This is how steel gets its strength more than pure iron. Typically carbon percentage in steels is 2% and alloy beyond 2% carbon is called as cast iron. The maximum carbon that can stay in the lattice structure is 6.67% by weight after which it forms cementite (Fe3C).

What is Rust?

Iron gets oxidized to iron oxide in the presence of oxygen and this is what is commonly known as rust. Rust not only deteriorates the surface appearance but also lowers the strength and mechanical properties of steel. Plain carbon steel is susceptible to forming rust if not coated with anti-corrosion paints.

What is Stainless Steel?

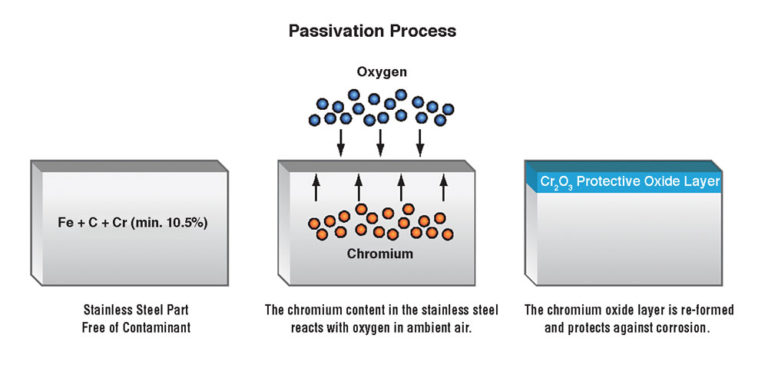

The way to prevent steel from reacting with oxygen is by adding any other element to steel so that it can more quickly react with oxygen thus leaving the iron in the steel as is. Chromium is more reactive than iron hence 11 to 18% chromium is added to steel that makes stainless steel stainless. The more chromium in the composition the more resistance it offers against corrosion. When there is oxygen in the environment of the part, the chromium atoms on the surface react with oxygen to form chromium oxide which further prevents it from reacting with oxygen. The process of exposing the surface to oxygen so that a quick layer of chromium oxide layer is formed is called passivation process.

How Stainless Steel is used in Manufacturing

Stainless steel is used in CNC machined parts and metal 3D printed parts. Stainless steel is also used in making tools and dies for plastic injection molding.

Grades of Stainless Steel

Type 303 – This has some sulfur added to make it soft and suitable for machining. 303 is mostly used in CNC machining. It is non-magnetic and does not change its structure upon heat treatment and hence is suitable for machining as the heat generated due to the cutting tool does not affect the strength properties of the steel.

Type 304 – This has less sulfur added than in 303 and hence it is relatively more corrosion resistant.

Type 316L – This is a special stainless steel alloy with low carbon content and added molybdenum. This makes it even more corrosion-resistant than type 304. Low carbon content does not carburize or give off heavy fumes making it suitable for welding and metal 3D printing. This type is mainly used in marine application parts that are in contact with salt water.

Type S136 – This is special high pure stainless steel. It is used mostly for plastic injection mold tools that need very high surface polish.