Day: September 16, 2016

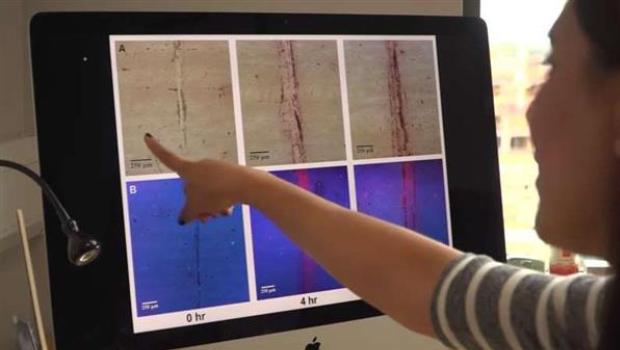

New 3D Scanning Techniques of the Bones using Gold Particles

September 16, 2016

No Comments

Read More »

KLM Airlines Serve Fresh Draught Beer from the First ever 3D Printed Beer Trolley

September 16, 2016

No Comments

Read More »

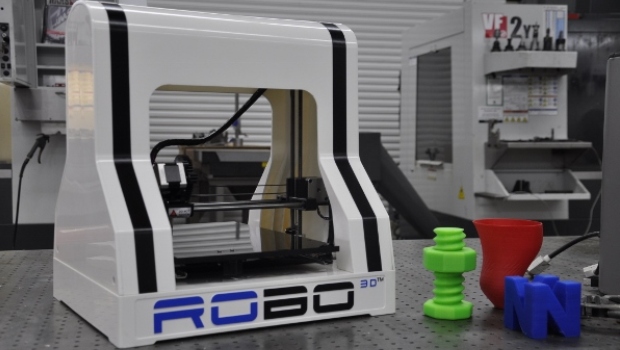

Winbo Smart Tech- A leading 3D Printing and Manufacturing Company

September 16, 2016

No Comments

Read More »

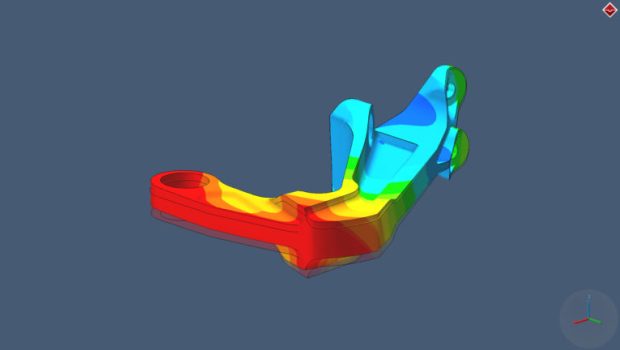

Simufact Additive Technology will Aid 3D Printing for Better Performance

September 16, 2016

No Comments

Read More »