Optomec’s Aerosol Jet technology has been devised to give out greater benefits of 3D printing technology. It enables the use of additive technology over varied surfaces using different materials.

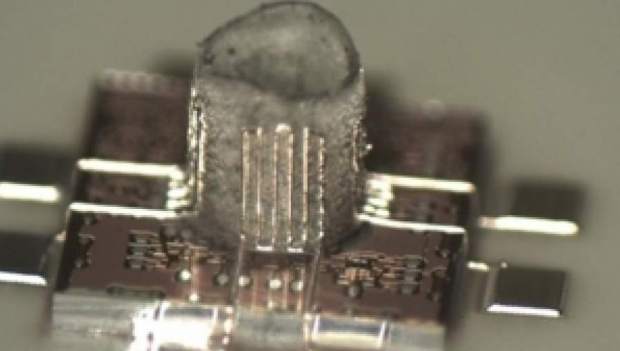

With the launch of Aerosol Jet, micron-scale 3D structures can be easily printed without the support of materials like photopolymers and composites. The latest technology will aid the users in making 3D parts from a single machine, as new structures can be printed with essential components like antennas and sensors.

This breakthrough technology enhances the fabrication process by minimizing the processing steps and reducing the quantity of materials used. This makes the Aerosol Jet 3D micro-structure printing a reasonable and environment-friendly technology.

The Aerosol Jet fine feature printing capabilities were combined with the proprietary in-site curing to achieve this Jet 3D printing technology by Optomec. This process allowed for quicker solidification tasks. This jet printing allows local material deposition and local curing processes, which is a requisite for creating high-resolution products.

The electronics and biomedical industries will be the best gainers of this technology. The output of the jet printing results in microstructures which can be printed onto semiconductor chips, industrial parts, medical devices, and a host of other existing products for all these fields.

Optomec –

Optomec is a private organization that deals in Additive Manufacturing systems. Aerosol Jet Systems has been patented by Optomac for printed electronics and the LENS 3D Printers for manufacturing metal parts are used by industry to improve performance and minimize the production costs. All these 3D printing technologies work with a huge array of functional materials like electronic inks, structural metals, and biological components.

Optomec has rapidly prospered and has 200 marquee customers around the globe. It produces components that can be used in the Energy, Life Sciences, Electronics,and Aerospace industries.

Source: 3dprintingindustry.com